Fiber Cement board for villas,high building-003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

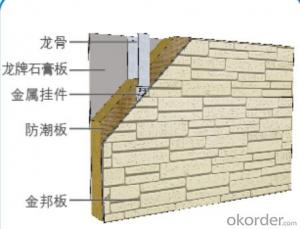

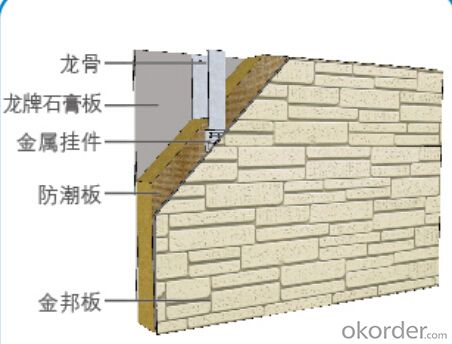

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: Can cement board be directly approved for cement?

- If the direct batch of cement once the surface of the water oxidation. The practice of this situation should be clean water with cement board, then brush a layer of cement paste, cement paste on the basis of cement mortar or other surface layer.

- Q: What exactly are fibre cement nails and what are they used for and a description.

- Not sure your spelling is correct, but cement board such as DUROCK uses special screws for installation. No fiber cement board uses nails they all get installed with SCREWS

- Q: I have an existing hardwood floor that I want to tile over (it's not in good condition). Can I put cement board then tile directly onto the hardwoods or do I need plywood on the hardwoods then cement board then tile? I don't want the floors to be 2 thick in addition to the hardwoods.

- Hillbill gave you good advice. I went to the site he recommended. It's straight up. I would add this; what you're looking for when you're done with the cementatious board is level. And, screws are better than nails on a wood floor.

- Q: Lightweight composite wallboard can not be attached to the wall

- Light, economical, cost-effective. Infrastructure design began to use lightweight partition, can greatly reduce the structure and the basis of cost, and optimize the beam and column structure, the overall layout of the room more reasonable, more use of the function. Increase the use of area, improve the construction period. Economic benefits are more superior. After the use of lightweight composite wall panels, the weight of the building is reduced, the cross-section of the component is reduced, the seismic force is reduced, so that the overall force has improved, the internal force of the beam and the column is reduced accordingly, so the reinforcement is also reduced , And reduced the structural cost.

- Q: Light steel keel cement board is what

- Cement board is a cement as the main raw material processing and production of a building plate, is a between the gypsum board and stone, free cutting, drilling, carving of the building products, with its superior to gypsum board, wood fire , Waterproof, anti-corrosion, pest control, sound insulation and far lower than the price of stone and become the construction industry widely used in building materials. The cement board is prefabricated and also cast.

- Q: What is the fiber used for cement foaming?

- Cement foam fiber called polypropylene short fiber, also known as PP fiber or short fiber to polypropylene as raw material, with a special production process and surface treatment technology to ensure that it has excellent dispersion in the concrete and the cement matrix grip Force, and anti-aging is good, can guarantee long-term effect in the concrete.

- Q: What is a cement board?

- Cement board of his material is made of cement can basically say that no advantage is not afraid of water equipment can do with the best home Do not fool yourself that thing is generally used in the kitchen bathroom package with water column with the above can be attached to the wall, but can not take long and wall The connection will appear where the cracks will be very ugly if the column would like to stick that small red brick and then tiling

- Q: What does the glass wire add to the cement?

- In the cement board plus glass fiber to improve the flexural strength of compressive strength, will not be easy to break

- Q: Its a baffle over an old fireplace where a gas heater has been installed. A cement based repair was hopeless, builders glue lasted a while but eventually busted when heater used on high for lengthy period. Crack getting bigger so need to get it fixed before a re-installation becomes necessary. Thanks.

- you could use a fire cement, that they use to seal coal and wood stoves,it comes already mixed,so you just spread it and level it,and it dries in no time at all,and it is designed for high temperatures

Send your message to us

Fiber Cement board for villas,high building-003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords