Fiber Cement board for villas,high building-004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

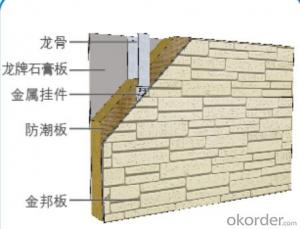

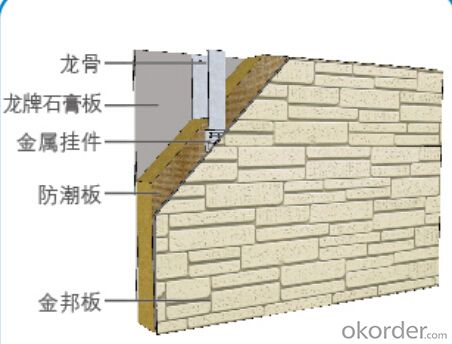

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: We recently hired a contractor to remodel the entire bathroom due to water damage. We are getting close to tiling. There is a tub going in then the walls will be tiled for the shower.The contractor put green board in the entire bathroom first. Then he put water barrier paper over the green board in the areas that will be tiled. Then put hardy backer cement board over that. Is this a good way to do it? There is no cement board below a certain height because the tub will be there. I wasn't sure if this is a good way to do it?

- Excellent way to do it.. The green board, vapor barrier and the cementrous board is one of the best tiling techniques for water protection. edges must be treated for the tile , either in a special tile trim ( most are called an A 4200 but there are other trims, depending on the type of tile you have) or the metal edge to finish it off. The person is doing it correctly. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Do you have to tape and fill seams on cement board when applying ceramic tile over it like when doing drywall?

- Yes, you'll use fiberglass mesh tape to tape the seams and a coating of thin-set mortar

- Q: how do I drywall over cement in a basement? How do i attach the drywall to the walls?

- May I suggest that you seal the basement walls before beginning the rock job? (sheet rocking)

- Q: Does the cement board go over the lip of the tub, or does it sit on that lip?

- it needs to go over it so water doesnt get behind it

- Q: I'm redoing the deck in my back yard. I've discovered the possibility of using deck tiles (wood slats, or slate, etc.) but not until after I ripped up the existing boards. There is a cement slab under my current deck. Could I just install the deck tiles on that, or would there have to be some sort of drainage system underneath? Thanks for the help!

- put them on the cement no drainage required

- Q: 60 thick foam cement board Ⅱ how much noise

- Foam cement board is A-class non-combustible inorganic insulation materials, have good fire performance, 1200 degrees high temperature baking 3 hours, still maintain integrity, used in buildings, can improve the fire performance of buildings. Because of its closed cell rate of> 95%, which has a good thermal insulation properties.

- Q: I need side and rear clearance for a 15 year old wood stove. The 2x4 walls are covered with cement board and ceramic tiles. Behind that is a foundation wall.

- That information should be on the stove, on a little plate on the back, and it should also be available from the stove manufacturer. Every stove is a bit different. You can also check with your local building inspector or a woodstove installation guy to find out what the local regulations say. I hope you're not planning to install this stove without a permit. That will void your insurance if there's ever a fire.

- Q: How do I remove dried cement from door & running board?

- Try good ole' WD40 it's know to take tar and alot of other road grime off cars.

- Q: The original floor pull up the steel in the layer of cement mortar, safe?

- Laying of steel on the concrete floor is not much of the load on the receiving plate, and the laying of steel on the 4 m wide plate is helpful only to the limitations of the board near the wall

- Q: I'm installing a stone back splash behind my bathroom sink - 16 SF. The wall is currently painted and I want to make sure that the stone and thinset adhere properly. Should I sand the wall with 80 grit sandpaper and apply the thinset/stone or should I put 1/2 or 1/4 plywood down for better adhesion? Perhaps cement board?

- Ideal way is to do a cement board as a backer board but since its in a non wet area,( not exposed to direct water) you really don t have to.Roughing the area up is always a good idea and won t hurt a thing. I d never do a wood backer in a moist and humid environment, It can expand from moisture and break the bond. Any questions you can e amil me through my avatar and check my qualifications there. GL

Send your message to us

Fiber Cement board for villas,high building-004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords