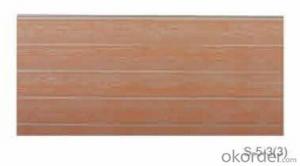

Fiber Cement board for villas,high building-013

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: What do you use under the tiles, and do you still use grout as well?

- Normally you install tiles over a concrete slab using modified thinset for exterior use. Regards, Dale

- Q: As an artist, I'm experimenting with plaster and cement.As a resident of a temperate zone, I'm wondering about temperature, curing times, and bonding to substrate.I'm working on square pieces of particle board. I rough up the surface with a wire brush to improve bonding to the substrate.Both plaster and cement create heat as they solidify. Are either impaired by a low (and possibly sub-freezing) temperature? I have a makeshift oven that can reach 110 to 120 degrees (F) regardless of the outside temperature. Will heating cement or plaster to this extent improve its ability to bond to wood? Might it only reduce setting time?

- The British give this name to modern day cement. Ordinary Portland cement,sulphate resistant cement, white cement and Grey cement and so on. Most have chemical name but Portland is a patent name.

- Q: What is the cement pressure plate, what is the use of it?

- With light, high strength, waterproof, anti-corrosion, fire, large format, good processing, improve construction efficiency and so on. Widely used in civil and industrial buildings. Can be used for building floor, interior wall panels, exterior panels, ceiling panels, curtain wall panels, composite wall panels, insulation materials, roofing and other parts.

- Q: How to make a cement board

- In advance with a board made of a box, four corners and then pull the cable to prevent the shift, put the plastic cloth can be. And then use the No. 8 wire on both ends of the hook, put into the box, with fine wire tied to make it a net (outside the sale of ready). A small amount of some cement into the sand, the proportion of this cement to be larger 1: 3. Wire to the prefabricated plate thickness of half, began to put a lot of cement sand, smoothing at the same time, with the hammer hitting the surrounding wood. OK. At least 10 days to health, summer 5-7 days can be. Do not water in winter.

- Q: I have 9 asbestos tile on concrete floor. Can I put cement board over tile this then install ceramic tile?

- Yes,be sure asbestos tile is as flat as possible and be sure to screw down boards correctly.For best results,pull up tile.

- Q: This is behind my vinyl siding and above my drop tile ceiling.

- It would most likely be asbestos because nobody in there right mind would cover Hardi with vinyl.

- Q: How to maintain cement board

- Cement mortar plaster to water conservation, to avoid cracking, is scientific, it is necessary to do so.

- Q: are you able to mountain board not only on dirt but also on surfaces like cement, for ex: a street?

- you probably could

- Q: do I need to put down a vapor barrier or cement board or can the hardwood be glued down and the tiles with thinset? Also what type grout should I use on floor and wall tiles?

- Vapour barrier or damp proof should be done before the concrete slab. In this case floor tiles could be laid directly on to the floor slab, whereas hardwood floor on wp plywood or timber framework with vapour barrier beneath.

- Q: I've taken up old linoleum tile, chip board, and two other layers of linoleum to get down to an oak floor in my bathroom. This has a felt-like paper uniformly adhered to it that must have been the backing for the first linoleum layer. I'm going to put down Hardi-backer, then tile. Do I have to take up the old tile backing material before I put down the hardibacker? It's very difficult to remove. Thanks!

- it is ok to go over that thin layer of paper

Send your message to us

Fiber Cement board for villas,high building-013

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords