Fiber Cement board for villas,high building-002

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

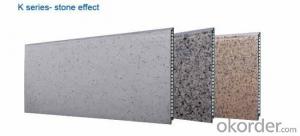

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

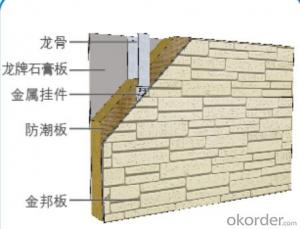

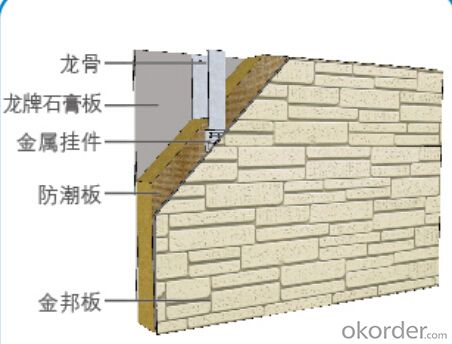

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: Production of fiber cement board copy method has what characteristics

- The fibers are oriented in two-dimensional plane orientation, and the direction of the fiber is mainly in the direction of the main stress of the plate. Through other means of subsidies, can make the fiber arrangement direction to meet the requirements of different products.

- Q: the cement boards are ahold by 1 nails

- Hardyboard is a composite/concrete siding that may work. If your boards are only slightly damaged you may be able to patch them with concrete patch then repaint. A lot cheaper than replacing.

- Q: FC sound-absorbing board is what material

- FC board is made of pressurized fiber cement board as panel, with sandwich material in the factory processing production of composite wall panels.

- Q: I've removed the old cement boards and I've put new ones up on the shower walls. My tile will not go to the ceiling. I'm at the step where I need to apply thin-set and tape to all of the cement board seems. What do I do at the seem that transitions from cement board to sheet rock?

- Yes tape those seams too. Make sure you nail the dry wall there too w/ a galvanized roofing nail. You may have to do so floating w/ thin set to get it flush but it ll work fine. The thin set , when gluing to dry wall needs to be a fresh batch or just a BIT looser and wetter since dry wall will absorb the thin set fast. Not wet wet just a bit looser. Any questions you can e mail me thru my avatar and check my qualifications there GL

- Q: I am laying a new tile floor over plywood subfloor. I have Durock cement backerboard. The area I'm covering is only 4'3 x 6'8. I don't really want to put the money out for power saws ($60+) so I am planning to use a hand saw. What kind is most appropriate? Can I use a small utility knife for the smaller details?

- You can actually just score it like drywall & snap it.

- Q: Would you recommend putting crazy glue in the draft boards locks, or cement?

- When was there ever a non-military draft? I prefer crazy glue because it sounds more fun that cement.

- Q: I've done the hard way - bunches of expensive special screws. I found that to be expensive and time consuming (and therefore back breaking). It seems like it takes just as long to do the backer board as it does to do all the remaining steps with the tile. Can I use nails? If so, what kind? Thinset and nails? The subfloor is plywood with old vinyl tiles, I have no intention of remove the old vinyl tiles first. Please reply if you have personal experience with an alternative. Thanks!

- There are a few factors that need to be considered. What is your subfloor? If its concrete and the vinyl is secured very well, then you can lay over it provided you put an acrylic additive in your thinset. This will help the bond to the vinyl. Also by doing this the vinyl will act as a crack supressant to the tile and protect against any cracks from your subfloor moving up to the tile. If you have a wood subfloor, you should remove the vinyl, install a 1/4 backerboard(not 1/2) and then install the tile with a modified thinset.

- Q: What is the difference between cement calcium silicate board and cement fiberboard

- Silicon calcium board mainly composed of gypsum, from the siliceous materials (diatomaceous earth, bentonite, quartz powder, etc.), calcium material, reinforced fiber as the main raw material, through the pulp, into blank, steaming, surface sanding process And made of light plate.

- Q: Standard cement prefabricated board load capacity is a square how many kilograms, thank you

- Prefabricated floor is generally hollow board, crack is a common quality, the overall poor, the advantage is the floor thick, sound better than the cast. Many places prefabricated boards are off, but are not forced. Or according to the actual situation around, economic conditions, the general type of building to segment the solution.

- Q: I currently have a cheap ceramic tile on my bathroom floor. It is set on cement board. I would like to replace it with a slate-like porcelain tile. Can I simply remove the ceramic tile or do I have to also tear out the cement board and replace it? How big of a project is this? I previously installed porcelain tile on a plywood floor over cement board and am wondering if the demolition creates a bigger problem.

- You could lay over what is there if the ceramic isn't slick or shiny on top. Getting off the old may not be as hard as one would think. Then again it may be a bear, I'd smack one with a hammer and just see how hard it would be to get out. This would not create such a height gain in the long run. If it is a nightmare then I'd cement the broken tile you took outs spot and go over top what is there if possible. Getting the old cement board completely out I believe would be a chore but I may be wrong.

Send your message to us

Fiber Cement board for villas,high building-002

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords