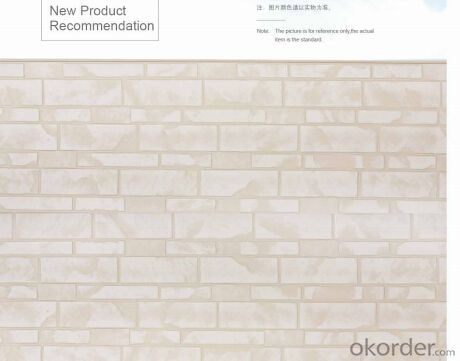

Fiber Cement board for villas,high building-009

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

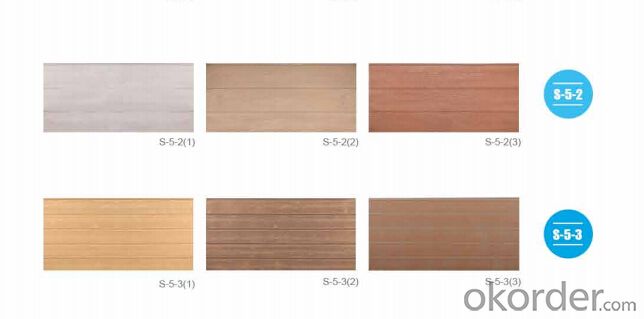

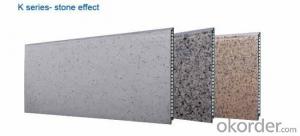

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: My fear is that I will trap moisture where it shouldn't be. Is there such a thing as overkill?

- No problem. i dont call it overkill. I would rather do it know than wish i had.

- Q: Yesterday I started a job at a warehouse store. This store, being a warehouse has cement floors. I have a pair of walking shoes I wear with added inserts for more comfort, but after my shift yesterday, I could barely walk because of the pain in my hips, knees, foot/leg joint, and my ankles. I know that arthritis runs in my family, and that other family members have had problems when dealing with cement floors. I'm only 23, but I know arthritis can start that young (I also know my knees are total crap because of sports). So my question is, could this pain be from walking on the cement floors all day, or is this just random? I never had this happen this bad before, and have never had to be on cement floors that long either.

- Hi there: I know this the floors will just kill my feet when working on cement. You have a fine day..

- Q: How to brush latex paint on the cement board

- Conservation: latex paint brush finished after 4 hours will be dry, but the dry film has not reached a certain hardness, which will care, it is simple, 7-10 days do not have to scrub or any contact with the wall Move can be.

- Q: i am going to be installing tile in my bathroom as a tub surround.i am wondering what backer board is needed. if i am using a membrane such as kerdi, is drywall a good enough backer or do i need cement board. if i need cement board, do i need the membrane? what products do you suggest for best installation. i will also be doing a walk in shower. are there any differences to be aware of compared to the tub surround shower style.

- Tile doesn't flex. Drywall does. You need a hard surface to lay tile, or the grout joints will crack, water will get in, and your tile will promptly fall off. Real tile backer board (the kind that's made out of fiber re-enforced cement) is the only decent solution for installing tile over a wood frame. Hardibacker or any other modern garbage designed to make something seemingly easier, just turns into a nasty headache a year later. Also be sure to use real thin-set mortar, and real grout. That adhesive grout is just acrylic caulking with some sand added, tiles will fall off if they get wet.

- Q: I know I could hire someone with a curbing machine, but it is way more expensive than I want to pay and I want to do it myself so I can customize it to my yard. I've known people who have been able to do it themselves.What tools do I need?

- not a real easy diy job but have fun

- Q: We are redoing a small bathroom and I want to redo the old tile and also add some additional tile around some of the other walls. We are planning to use cement board around the tub, but do I need to rip out existing wallboard around the vanity and other walls where I want to add new tiles and replace it with cement backer board? Or should I just add the cement board on top of the existing wallboard in the places I want to add new tile ( I was thinking about maybe tiling halfway up some of the other walls). Thanks!

- Cement board is only needed around a tub or shower, Adhere the tile with a modified thinset adhesive. Use mastic (glue made for tile) on the existing drywall rather than thinset on the rest of the room.

- Q: What are the drill bits for the cement board?

- See how much you need to drill the general small hole hammer can drill the general hammer can be dry to 28 mm imported hammer can be dry to 40 mm

- Q: Redoing my tub and shower tearing it out and instaling new walls and tile thanks.

- I would go for the cement board where the tile is going to be in the tub/shower area and the green board elsewhere in the room.

- Q: I have a 5x20 room off my basement which sits under my front porch. All four walls of the room are cement block all the way up to the ceiling which is the cement slab from the porch above. There is a wood ceiling in the room that has gotten wet from leaks above. Is it safe to remove the wood joists and plywood in that room, fix the leaks and replace it? This doesn't support any weight from the slab above, does it? I assume that it was probably used as the bottom of the form when the slab was poured. Also, when I replace the ceiling, can I attach the ledger board using concrete sleeve anchors? Can these be fastened into the block wall? I'm not sure if they are hollow or have been filled with gravel or concrete. I plan on using the ledger board to fasten joist hanger to and frame back up my ceiling for insulation and wiring. The current ledger is attached with masonry nails. Any thoughts?

- Your ceiling may very well be no more than the bottom forms for the slab, but you really need to make sure. Attempting to seal the concrete slab from the underside isn't advisable. Concrete draws moisture, so you will always have a seepage problem after you're finished. I'd suggest sealing the slab on the surface and make sure it quit weeping before proceeding with the remainder of your project. Not all concrete blocks are filled. To secure your ledger board I'd suggest using a lag bolt with a lead spread type toggle. Drill into the block and insert to lead, which will hold the lag bolt. Hope this has been some help. Good Luck

- Q: Unfortinatly i already have the tile but i was hoping i could use self leveling cement then atattch the tile to it. is this even a posabilityor should i use hardyback board and if i do how can i atattch it to the cement

- I used the self leveling concrete mixture and sure enough, it worked great. Just make sure you do your prep work to ensure excellent results.

Send your message to us

Fiber Cement board for villas,high building-009

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords