Fiber Cement board for villas,high building-005

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

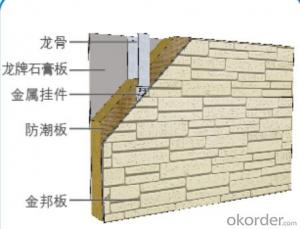

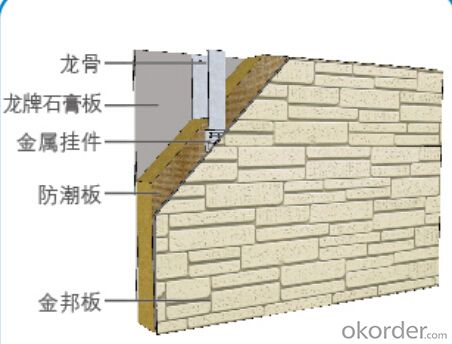

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: What exactly are fibre cement nails and what are they used for and a description.

- Not sure your spelling is correct, but cement board such as DUROCK uses special screws for installation. No fiber cement board uses nails they all get installed with SCREWS

- Q: What are the drill bits for the cement board?

- If you can only use a large diamond (diamond drilling machine) usually able to dry to a diameter of 200 if the professional ability to 400-500 mm Now the big demolition company has a capacity to 1 meter in diameter

- Q: I used a razor but it killed the blade in about two seconds. Is there a special saw for this stuff that won't make a huge mess?

- Use a utility knife and score it just like you would drywall. Once scored, snap it to break it apart. Even though the blade gets dull it does not require much to snap the cement board.

- Q: I know that cement board can be installed over a vinyl floor, but can it be installed over wood laminate? I am planning to install 12x12 slate tile and want a good foundation without having to do any more work than necessary. Thank you.

- NO! The laminate is a floating wood floor, and you want your cement board firmly screwed to the subfloor. You will need to remove the laminate floor. Sorry.

- Q: What is the average price for hardieplank(cement board) installation?

- Anywhere from $10 to $15 per square foot depending upon how cut up it is. Large walls with not many cuts - $10. Small expanses with lots of angles and cutting - $15 of more if really complex. This includes the hardie product, the water proofing and the fasteners.

- Q: How the cement pressure plate sticks on the brick

- Base treatment: the dust, debris thoroughly cleaned, no hollowing, cracking and sand and other defects. Pin line: before the construction of the wall around the height of the pop-up control line, in the ground pop-up cross-line to control the floor tile size.

- Q: i glued a piece of regular printer paper to a piece of matboard as part of an art project. since i applied rubber cement to both the paper and the board, it bonded quite strongly. the problem is that now i have to remove the paper with the least amount of damage to the matboard. the paper is white and the board is black. its been over a week since i glued the two together. HELP!! i need this for school and it has to look good...any suggestions??im going to throw the paper away, so that can be damaged in the process. no problem.

- hair dryer to warm it and peel real slow...?

- Q: I am planning on doing cement around bath and shower in my home. i already have cement backer board up and wire mesh screening. what do i use to make it not crack and smooth and what material do i use

- You're welcome to do whatever you want, but concrete is porous like grout. Ever seen nasty grout? Even sealed grout gets disgusting without proper maintenance (ie squeegee) and cleaning. Imagine that all over the wall. Even if you make it ultra smooth and seal it my guess is that this would get disgusting in a hurry...unless you happen to have a power washer in your bathroom... ;)

- Q: or can i leave the seams alone? if i have to tape them what tape do i need and what compound do i need? thanks for any help!

- There's no need to tape the seams of cement board, as long as you get a good close fit it should be ok. You've made a wise choice using cement board, at least on the lower half of the shower enclosure area, greenboard, while being somewhat moisture resistant is not impervious to water damage. It should be used above the cement board and will do a good job there. The seams in it will need to be taped, at least above the top edge of the surround.

- Q: What are the densities of tiles and cement

- In the production and processing process, wood in the wood board of wood components through non-toxic chemical mineralization after the fire produced. These treated mineralized wood components combine with the Portland cement base to increase its strength and toughness, resulting in significant structural features and excellent quality of Portland cement: fire, moisture, Corrosion, pest control, and durability. The overall structure of the wood fiber board makes it resistant to impact and easy to process. Due to the close structure, high density, wood fiber reinforced concrete board sound insulation is excellent, and affordable,

Send your message to us

Fiber Cement board for villas,high building-005

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords