Exterior Light Post Fixtures

Exterior Light Post Fixtures Related Searches

Outside Post Lighting Fixtures Outdoor Ceiling Light Fixtures Post Lights For Outdoors Commercial Outdoor Post Lights Solar Lamp Post Light Fixture Stainless Steel Light Fixtures Exterior Wall Led Lights Ceiling Spot Light Fixtures Indoor Spotlight Fixture Industrial Light Fixtures Large Led Light Fixtures Led Replacement Fixtures Led House Light Fixtures Replacement Light Fixture Parts Low Profile Light Fixtures Lamp Light Fixture Parts Small Led Light Fixtures Parts For Light Fixtures Led Track Light Fixtures Small Spot Light Fixture Office Lighting Fixtures Outdoor Lighting Systems Warehouse Light Fixtures Fluorescent Ceiling Light Fixtures Wall Light Fixture Parts Exterior Driveway Lights Outdoor Pillar Mounted Lights Track Light Led Fixtures Wall Mount Light Fixture Outdoor Kitchen LightingExterior Light Post Fixtures Supplier & Manufacturer from China

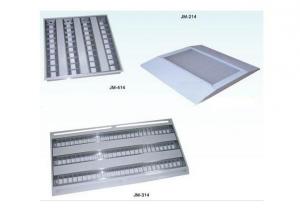

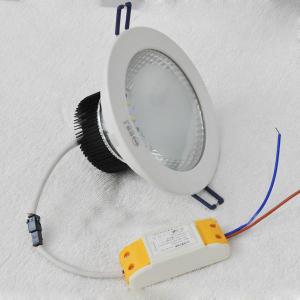

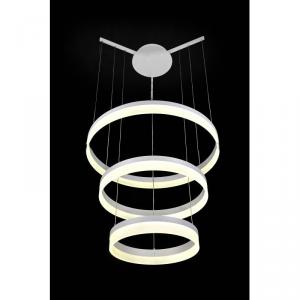

Exterior Light Post Fixtures are a range of lighting products designed to illuminate outdoor spaces, including pathways, driveways, and gardens. These fixtures come in various styles and designs, such as traditional, modern, and decorative, to suit different architectural preferences and outdoor settings. They play a crucial role in enhancing the aesthetic appeal of outdoor areas while ensuring safety and visibility during nighttime.Exterior Light Post Fixtures are widely used in residential, commercial, and public spaces to provide adequate illumination and create a welcoming ambiance. They are particularly useful in areas where visibility is essential for safety, such as parking lots, walkways, and entrances. These fixtures can also serve as a deterrent for potential intruders, adding an extra layer of security to properties. By choosing the right type of exterior light post fixture, homeowners and businesses can create a well-lit and secure environment that is both functional and visually appealing.

Okorder.com is a leading wholesale supplier of Exterior Light Post Fixtures, offering a vast inventory of high-quality products at competitive prices. With a commitment to customer satisfaction, Okorder.com ensures that their products meet the highest industry standards and are available for quick shipping to customers worldwide. By partnering with Okorder.com, businesses and individuals can access a diverse selection of Exterior Light Post Fixtures to suit their specific needs and preferences, making it a reliable choice for all outdoor lighting requirements.

Hot Products