Non-Asbestos Houses Installation Fireproof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Can be used in washrooms as the ceiling, partition and backer boards. Additionally, Due to the features of fire prevention, thermal insulation, mildew proof and moisture proof, Bestinboards are also applicable to places where high security is needed.

Product Features:

1.Fire-retardant

2.Thermal-insulated

3.Mildew proof

4.Moisture proof

5.Sound insulated

6.Low moisture and water absorption

7.100% asbestos free and other hazardous substances.

Product Advantages:

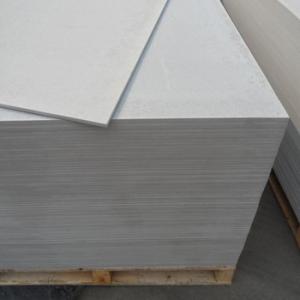

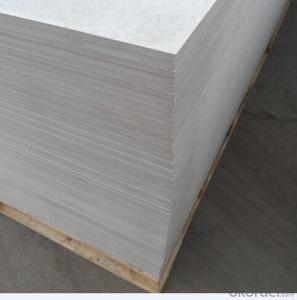

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

Trade Term

1. Payment: T/T

2 .Lead time: Samples:15 Working days;

3. Shipping freight are quoted under your requests.

4. Shipping port: Foshan,Guangzhou or Shenzhen port, Mainland China.

5. Discounts: discount based on the order quantity.

Certificate

Products are Calcium Silicate Board (Fiber Cement Board), exterior wall plate, Facade Board and lining board, etc. Our products have passed ISO certificates. CE, TUV Certificates are on progress.

Product Specifications:

| Size | Standard Size | Size:1220*2440*4/6/8/9/10/12/15mm |

| Appearance | Surface | Surface:Un-Sanded/Sanded/Polished; |

| Edge | Square/Recessed/ | |

| Physical Properties | Density | 1.2-1.3g/cm3 |

| Bending Strength | Cross > 16Mpa Parallel 60-70Mpa | |

| Moisture Movement | <0.20% | |

| Water Absorption | < 0.1% | |

| Water Contain | <6%(Under EMS condition) | |

| Thermal Conductivity | 0.12-0.15 w/(m •k) | |

| Non-combustibility | GB 8624-2006 Grade A1,CE EN 12467:2012 Grade A1 | |

| Water Impermeablility | Traces of moisture appeared on the under surface of the sheet,but no formation of drops of water on the underside of the sheet after 24 hours. | |

| Freeze-thaw | Not have cracking and layering after freeze-thaw cycles 25 times. | |

| Application | Interior Ceiling,Interior Patition, Bottom Liner | |

| Products Warranty | More than 20 years |

| Raw Material | Content |

| Cement | 44 % |

| Quartz | 44 % |

| Natural Fiber | 8 % |

| Suspension | 4 % |

| Composition of Finished Product | Content |

| Crystalloid of Calcium Silicate | 52% |

| Quartz | 30% |

| Calcium Carbonate | 10% |

| Cellulose | 8% |

Images:

- Q: Installation technology and process of external wall cement board

- Injection molding, foaming: then the slurry into the mold foam, foaming process for about 3-5 minutes; initial maintenance: after the completion of injection molding for several hours after the initial maintenance; stripping: foam foam insulation board to be completed Early cutting, with the initial strength can be stripping; cutting: with a certain strength of the foam insulation board blanks after stripping can be cut, cutting specifications according to the need to adjust the cutting blade; finished maintenance: foam cement insulation board maintenance Age should not be less than 7 days.

- Q: I'm making designs for a house I want to build. Initially I wanted to build the house out of primarily concrete, however because of where the house is going to be going, it's not really plausible to get that amount of concrete out there to pour at once (it would be extremely difficult to get a truck out there).So my next consideration would be to build an otherwise traditional frame and instead of using drywall on the inside, I would use cement boards to panel the walls, and go for a clean, future-industrial look. I was also intending on doing something similar to the exterior.However, cement boards obviously weigh significantly more than typical drywall panels, and my main concern is whether or not a regular wood frame would be able to hold that amount of weight. So would that pose a significant issue to the extent that I should also consider using steel for the entire frame, or at least as a support system, or should wood be able to hold up just fine?

- Wood is fine. I am building a house that is using the 1/2 HardieBacker cement board panels attached to sound channel that is attached to wood studs. Works well. Building Dept approved it.

- Q: What are the fiberboard specifications? Fiber cement board thick

- According to industry standards JC / T412.2--2006, fiber cement board is the industry's formal name, the domestic commonly used is 1200 * 2400mm * 4 - 30mm

- Q: I have a walk in closet with plywood pieces for a floor. Don't I need cement board installed before putting in wood flooring? Thanks for your help!!

- You dont need cement board . You would just install it over the plywood subfloor. Personally I would go down to Home Depot or similar store and look at their floring and talk to a salespersomn there. If you have not done this before you need to find professional help.

- Q: We recently bought a house with a corner tub in the master bathroom. There was a partially covered pipe for a shower head but the walls are not waterproof. Since the plumbing is there for a shower we would like to waterproof the walls and put in a shower head. Is there a chance the builder put up cement board but skipped tiling? Is there a way to tell without ripping the walls down? Also I'm wondering if we need to tear down the existing drywall and put up cement board or if we can just use a type of acrylic shower wall and caulk it really well. Any advice would be appreciated.

- Stick a push pin into the wall. If it's drywall it will go in and if it's cement board it won't go easily.

- Q: How much is the cement board?

- Good and bad can not say that you use there. It is in the construction and decoration are used on a wide range of .For example, the bathroom grid wall building exterior to do the shape. Fine decoration useful to make it decorative layer, the pursuit of some special The artistic effect.

- Q: i glued a piece of regular printer paper to a piece of matboard as part of an art project. since i applied rubber cement to both the paper and the board, it bonded quite strongly. the problem is that now i have to remove the paper with the least amount of damage to the matboard. the paper is white and the board is black. its been over a week since i glued the two together. HELP!! i need this for school and it has to look good...any suggestions??im going to throw the paper away, so that can be damaged in the process. no problem.

- Try pulling the paper off...and use your hand to ball up the rubber cement

- Q: What is the difference between cement calcium silicate board and cement fiberboard

- Silicon calcium board mainly composed of gypsum, from the siliceous materials (diatomaceous earth, bentonite, quartz powder, etc.), calcium material, reinforced fiber as the main raw material, through the pulp, into blank, steaming, surface sanding process And made of light plate.

- Q: Standard cement prefabricated board load capacity is a square how many kilograms, thank you

- In accordance with national standards: cast-in-place cement board bearing capacity is 250 kg / square meter, prefabricated board is 200 kg / square meter.

- Q: Ok, here's the situation:I have a covered porch on our house, and I need to replace its floor. Facts of concern: * It is a covered porch. There are four columns between the floor and roof, but I don't know whether they are actually supporting the roof. * It is currently floored with 1/2 plywood, which is rotting. No standing water involved; the texture prevents proper drainage and led to rot. * Under the porch is a basement room complete with wiring and such. We had planned to use oak tongue-in-groove, but have been warned away from it. Now we’re not sure what to use – we just know we don’t want to use plywood.Our questions:1. If I assume those beams are supporting the roof, I’ll need a jack. But what jack? Where do I rent one?2. I thought about using a thin plywood layer under some cement board, but what could I put on top, other than tile?3. Anybody have any other ideas for flooring? Where to get TIG cedar in Cleveland?Thanks!

- With your situation of having a room below your choices are very limited. First I would replace the rotted plywood with 5/8 pressure treated tounge and groove. You can cut to within a 1-1/2 of your exterior walls with a skill saw, I wouldn't worry to much about what is under the walls. Replace plywood and then top with 1/4 tile backer board and tile it. Complete your project by sealing your joints. If you need a jack, use the jack for your car, there usually rated for 20000 lbs

Send your message to us

Non-Asbestos Houses Installation Fireproof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords