EPDM Self-adhesive Waterproof Membrane for Green Roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

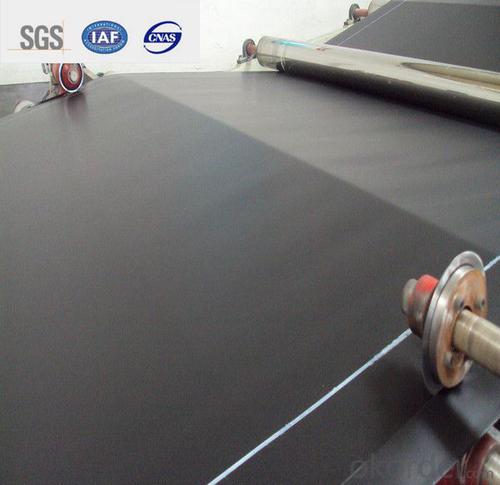

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

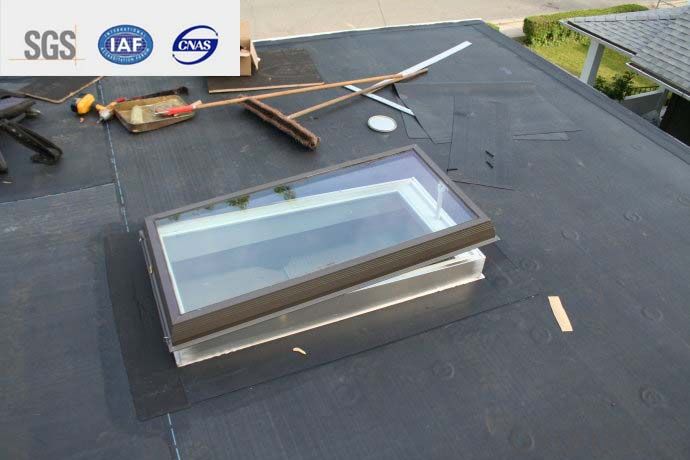

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used on metal surfaces?

- A waterproofing membrane is capable of being utilized on metal surfaces, providing protection against water infiltration. These membranes are specifically designed to safeguard various materials, including metal, from water damage. They are primarily composed of modified bitumen, EPDM, PVC, or TPO, which offer a resilient and impervious barrier. By applying a waterproofing membrane to a metal surface, one can effectively ward off corrosion, rust, and water-related harm. This makes it a suitable solution for shielding metal structures, roofs, or surfaces that are exposed to moisture or water. However, it is crucial to ensure that the chosen waterproofing membrane is compatible with the specific type of metal surface and that proper installation guidelines are adhered to in order to achieve optimal performance and durability.

- Q: Can a waterproofing membrane be used for a basement floor slab?

- A basement floor slab can indeed benefit from the use of a waterproofing membrane. Its purpose is to hinder the infiltration of water and moisture into the surface to which it is applied. This solution is highly effective in shielding basement floor slabs against potential water damage. By applying a waterproofing membrane to the basement floor slab, you can establish a barrier that effectively obstructs water from penetrating, thus diminishing the likelihood of water damage, mold growth, and structural problems. Moreover, a waterproofing membrane can also function as a vapor barrier, preventing moisture from rising through the slab and causing issues like dampness or excessive humidity levels in the basement. All in all, selecting a waterproofing membrane for a basement floor slab is a wise decision that guarantees long-term durability and protection for the basement.

- Q: Can a waterproofing membrane be applied over existing waterproofing layers?

- Yes, a waterproofing membrane can be applied over existing waterproofing layers. However, it is important to assess the condition of the existing layers to ensure they are sound and can provide a proper substrate for the new membrane. Additionally, proper surface preparation and compatibility between the existing layers and the new membrane should be considered to ensure a successful and long-lasting waterproofing system.

- Q: Can a waterproofing membrane be used in interior or exterior applications?

- Yes, a waterproofing membrane can be used in both interior and exterior applications. In interior applications, such as basements or bathrooms, a waterproofing membrane can be installed on walls or floors to prevent water or moisture from seeping through. This helps to protect the underlying structure from damage caused by water intrusion. In exterior applications, a waterproofing membrane can be applied to the exterior walls or foundations of a building to prevent water from penetrating into the structure. This is especially important in regions with heavy rainfall or high water tables. By creating a barrier against water, the membrane helps to keep the interior of the building dry and free from water damage. Overall, the use of a waterproofing membrane in both interior and exterior applications is essential for ensuring the longevity and durability of a structure by protecting it from water-related issues.

- Q: How much does a waterproofing membrane cost?

- The cost of a waterproofing membrane can vary depending on several factors. The type of membrane, the size of the area to be waterproofed, and the complexity of the installation can all affect the price. On average, the cost of a waterproofing membrane can range from $1 to $5 per square foot. However, this is just a rough estimate and the actual cost can be higher or lower based on the aforementioned factors. For example, a basic sheet membrane made of PVC or EPDM might be on the lower end of the price range, while a liquid-applied membrane or a more advanced system like a bentonite clay membrane can be on the higher end. Additionally, the size of the area to be waterproofed will impact the cost. Larger areas will require more materials, labor, and time, which can increase the overall price. Complexity of the installation is another factor to consider. If the area is hard to access or requires extensive preparation work, such as removing existing materials or repairing cracks, the cost may be higher. It is recommended to consult with a professional waterproofing contractor who can assess your specific needs, provide an accurate estimate, and recommend the most suitable waterproofing membrane for your project.

- Q: Can a waterproofing membrane be used on precast metal surfaces?

- Yes, a waterproofing membrane can be used on precast metal surfaces. The membrane acts as a protective barrier, preventing water from seeping through the metal and causing damage. It helps to maintain the integrity and longevity of the precast metal surfaces by keeping them dry and free from moisture-related issues.

- Q: Can a waterproofing membrane be used for airport runways?

- Yes, a waterproofing membrane can be used for airport runways. Airport runways are subjected to a significant amount of wear and tear due to heavy aircraft traffic, weather conditions, and potential fuel spills. A waterproofing membrane can serve as a protective barrier against water infiltration, which can lead to runway deterioration and damage. It can also prevent the penetration of fuel, oil, and other chemicals that can weaken the runway structure. Additionally, a waterproofing membrane can help to prolong the lifespan of the runway by reducing the effects of freeze-thaw cycles and preventing the formation of cracks and potholes. Overall, the use of a waterproofing membrane can enhance the durability and safety of airport runways, ensuring smooth operations and minimizing maintenance costs.

- Q: What is BSB waterproofing membrane

- Scope of application: 1. Polyester Felt-based elastomer modified asphalt waterproofing membrane for industrial and civil construction of the roof and underground waterproofing works. 2. Glass fiber reinforced polyester mattress base coil is suitable for mechanical fixed single layer waterproof, but through the wind load test. 3. Fiberglass mattresses are suitable for structural roofs and underground waterproofing works; 4. Exposure to the use of the upper surface of the insulating material for the opaque mineral pellets of the waterproofing membrane. 5. Underground engineering waterproofing should be used surface insulation material for the fine sand of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for water tanks?

- Water tanks can indeed utilize a waterproofing membrane. These membranes are specifically designed to halt the passage of water and effectively seal water tanks, guaranteeing their watertightness. Commonly composed of materials like bitumen, PVC, or EPDM, these membranes possess remarkable water resistance and can endure the challenging conditions typically present in water tanks. Moreover, waterproofing membranes can be applied to various surfaces, including concrete, metal, and masonry, making them versatile and suitable for different types of water tanks. All in all, the usage of a waterproofing membrane presents a reliable solution in safeguarding the integrity and longevity of water tanks by preventing water leakage and shielding the surrounding environment from potential water damage.

- Q: Can a waterproofing membrane be used for train platforms?

- Yes, a waterproofing membrane can be used for train platforms. Waterproofing membranes are commonly used in construction to provide a protective barrier against water and moisture. By applying a waterproofing membrane to train platforms, it helps prevent water ingress, which can cause damage to the structure and pose safety risks.

Send your message to us

EPDM Self-adhesive Waterproof Membrane for Green Roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords