EPDM Waterproof Roofing Membrane for Environmental

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Roofing Membrane for Environmental

Description Of EPDM Waterproof Roofing Membrane for Environmental:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Waterproof Roofing Membrane for Environmental:

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Specifications of EPDM Waterproof Roofing Membrane for Environmental:

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strenght,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

Applications of EPDM Waterproof Roofing Membrane for Environmental:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

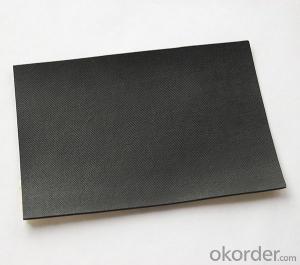

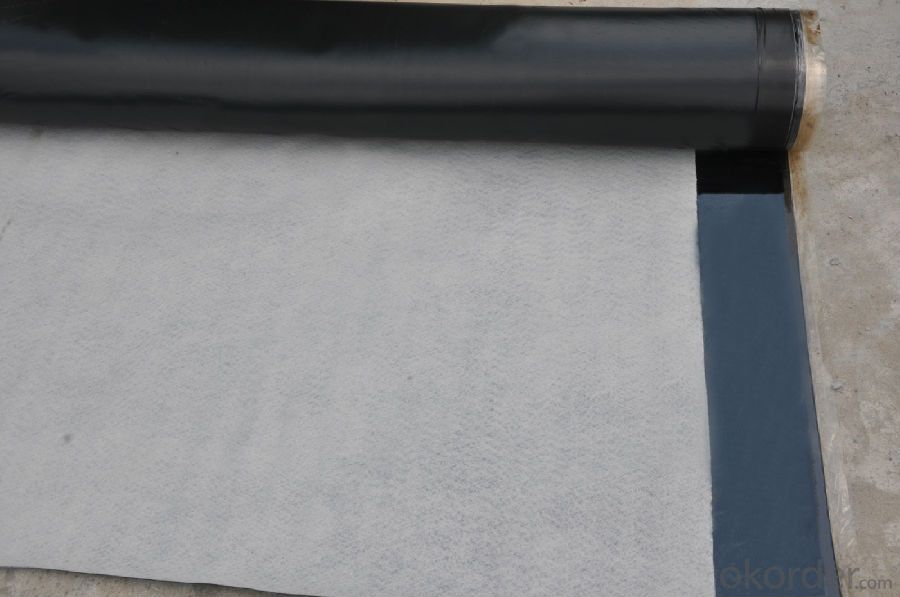

IMages of EPDM Waterproof Roofing Membrane for Environmental:

FAQ of EPDM Waterproof Roofing Membrane for Environmental:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in renovation projects?

- Yes, a waterproofing membrane can be used in renovation projects. It is a common and effective method to prevent water damage and leakage in areas such as basements, bathrooms, and roofs during the renovation process. By installing a waterproofing membrane, it helps create a barrier against water penetration, ensuring the longevity and durability of the renovated area.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Theaters and concert halls can benefit greatly from the use of waterproofing membranes. These membranes are commonly employed in construction projects to safeguard buildings against water damage by preventing water infiltration. They are applied to various surfaces, including walls, floors, and roofs, creating a barrier that stops water from seeping through. In the case of theaters and concert halls, where the protection of the building structure and equipment is of utmost importance, waterproofing membranes can be extremely advantageous. They play a crucial role in preventing water damage to delicate equipment like audiovisual systems, lighting fixtures, and musical instruments. Furthermore, these membranes ensure a dry and comfortable environment for both performers and audience members by preventing water leakage and moisture buildup. In conclusion, the use of a waterproofing membrane in theaters or concert halls guarantees the longevity and functionality of the building, creating a safe and enjoyable experience for all involved.

- Q: Can a waterproofing membrane be installed by a DIYer?

- Installing a waterproofing membrane can be done by someone who wants to do it themselves. However, it is important to keep in mind that the installation process can be complicated and requires careful attention to detail. It is crucial to thoroughly understand the instructions and guidelines provided by the manufacturer before attempting the installation. In addition, it is essential to properly prepare the surface in order to have a successful installation. This may involve cleaning, leveling, and priming the surface to ensure that the membrane adheres correctly. It is also important to choose the appropriate type and thickness of membrane for the specific application. Moreover, DIYers should have the necessary tools and equipment, like a trowel or roller, to apply the membrane accurately. Depending on the specific membrane and installation method, specialized tools may also be required in some cases. Considering safety measures is also important. It is recommended to wear protective gear and work in a well-ventilated area. Some waterproofing membranes may involve the use of hazardous chemicals, so it is crucial to follow all safety instructions provided by the manufacturer. If you are uncertain about your ability to properly install a waterproofing membrane, it is advisable to seek advice from a professional contractor who specializes in waterproofing. They have the knowledge and expertise to ensure a correct installation that will effectively protect your property from water damage.

- Q: Are waterproofing membranes resistant to oil and grease?

- Yes, waterproofing membranes are often resistant to oil and grease. These membranes are designed to create a barrier against water infiltration, and many of them are also made to withstand exposure to various chemicals, including oil and grease. This resistance is typically achieved through the use of specialized materials and coatings that are able to repel or prevent absorption of oil and grease. However, it is important to note that the level of resistance can vary depending on the specific type and brand of the waterproofing membrane. Therefore, it is advisable to consult the manufacturer's specifications or seek professional advice to ensure the membrane chosen is suitable for the specific application and level of oil and grease exposure.

- Q: Can waterproofing membranes be used on both horizontal and vertical surfaces?

- Waterproofing membranes possess the capability to be utilized on both horizontal and vertical surfaces. These membranes have been specifically engineered to furnish a protective shield against water infiltration, and they can be implemented on a diverse array of surfaces, encompassing roofs, walls, floors, and even subterranean structures. Their application is incredibly versatile, enabling them to safeguard horizontal surfaces, such as flat roofs or balconies, while also affording protection to vertical surfaces, including walls or foundations. The adaptability and resilience of waterproofing membranes render them highly suitable for a vast spectrum of construction projects, guaranteeing that water does not permeate and inflict harm upon the structure.

- Q: Can waterproofing membranes be used on retaining walls?

- Yes, waterproofing membranes can be used on retaining walls. Waterproofing membranes are commonly used on retaining walls to prevent water infiltration and protect the structure from moisture-related issues such as seepage, efflorescence, and cracking. These membranes act as a barrier that prevents water from penetrating the retaining wall and causing damage. They are typically installed on the exterior side of the retaining wall, providing an additional layer of protection against water intrusion. Waterproofing membranes come in various forms, such as sheet membranes, liquid-applied membranes, and cementitious coatings, and can be chosen based on the specific needs and requirements of the retaining wall.

- Q: Can a waterproofing membrane be used in bathrooms or showers?

- Certainly, bathrooms or showers can benefit from the use of a waterproofing membrane. In fact, it is strongly advised to incorporate a waterproofing membrane in these spaces to avert water damage and leakage. By serving as a barrier, the waterproofing membrane obstructs water from infiltrating through the walls, floors, and other surfaces in the bathroom or shower. Normally, it is applied prior to tiling or finishing the surfaces, offering an additional shield against moisture and guaranteeing that the underlying structure remains free from dampness. This not only aids in preventing the growth of mold and mildew but also extends the lifespan of the bathroom or shower.

- Q: Are waterproofing membranes suitable for bridge abutments?

- Yes, waterproofing membranes are suitable for bridge abutments. These membranes provide an effective barrier against water infiltration, protecting the abutments from moisture-related damages such as corrosion, deterioration, and leakage. They help extend the lifespan of the bridge and ensure its structural integrity.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- A waterproofing membrane is capable of protecting against the growth of mold or mildew, as they thrive in environments that are damp and moist. The membrane acts as a barrier, preventing water from entering the building structure. This effectively keeps the area dry and greatly reduces the likelihood of mold or mildew growth. Furthermore, waterproofing membranes often contain anti-microbial properties that further hinder the growth of mold and mildew. Nevertheless, it is important to remember that while a waterproofing membrane can offer substantial protection against mold and mildew, it is not a foolproof solution. It is crucial to ensure proper ventilation and carry out regular maintenance to prevent these issues.

- Q: Does a waterproofing membrane require any specific preparation of the substrate before installation?

- Yes, a waterproofing membrane typically requires specific preparation of the substrate before installation. The substrate needs to be clean, dry, and free from any debris, oils, or contaminants that may hinder adhesion. It may also require smoothing or leveling of the surface to ensure proper application and effectiveness of the membrane.

Send your message to us

EPDM Waterproof Roofing Membrane for Environmental

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords