EPDM Self-adhesive Waterproof Membrane for Roof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

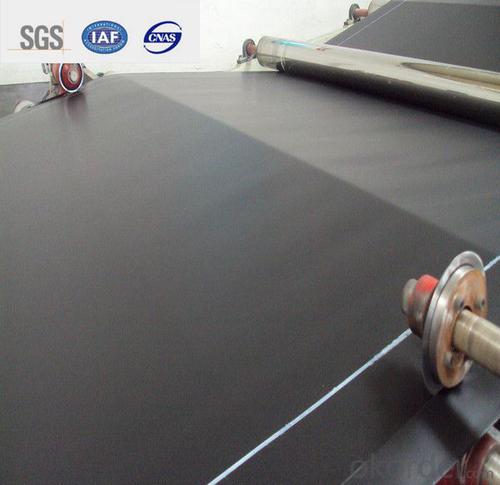

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

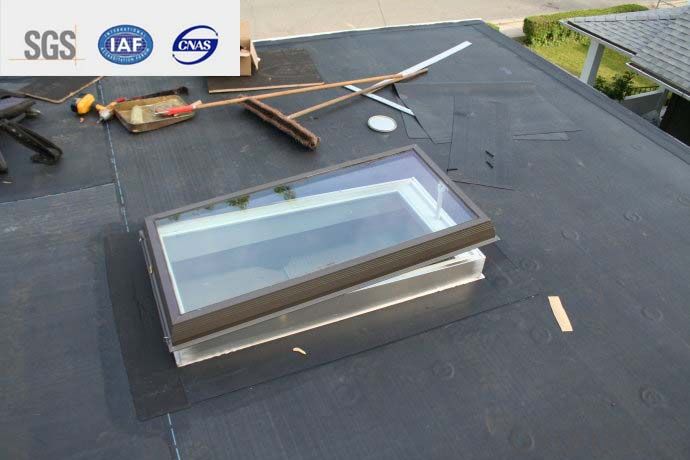

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in areas with high levels of salt or saltwater exposure?

- Yes, a waterproofing membrane can be used in areas with high levels of salt or saltwater exposure. Waterproofing membranes are designed to provide a protective barrier against moisture, including saltwater. They are often used in coastal regions, marine environments, or areas with high salt content in the soil to prevent water damage and corrosion.

- Q: Can a waterproofing membrane be painted over?

- Yes, a waterproofing membrane can be painted over. However, it is important to ensure that the membrane is properly prepared and any necessary primers or sealers are applied before painting. It is also recommended to use a paint specifically designed for application on waterproofing membranes to ensure durability and long-lasting results.

- Q: How does a waterproofing membrane handle temperature fluctuations?

- A waterproofing membrane is designed to handle temperature fluctuations by being flexible and resistant to thermal expansion and contraction. Temperature fluctuations can cause materials to expand and contract, which can lead to cracks, leaks, and other forms of damage. However, a waterproofing membrane is typically made from a durable and flexible material, such as PVC or EPDM, that can withstand these changes in temperature without compromising its effectiveness. When exposed to high temperatures, the membrane will expand slightly to accommodate the increased thermal energy. Conversely, when temperatures drop, the membrane will contract to maintain its integrity. This flexibility allows the membrane to adapt to the changing conditions without cracking or becoming brittle. In addition to being flexible, a waterproofing membrane is also designed to resist UV radiation from the sun. UV radiation can cause materials to deteriorate over time, leading to decreased performance and potential leaks. By incorporating UV stabilizers into the membrane's composition, it can withstand prolonged exposure to sunlight and maintain its durability even in harsh weather conditions. Furthermore, some waterproofing membranes have built-in insulation properties that help to regulate temperature fluctuations. These membranes can provide additional thermal resistance, reducing heat loss in cold weather and minimizing heat gain in hot weather. This insulation layer helps to stabilize the temperature of the underlying structure, preventing damage caused by extreme temperature changes. Overall, a waterproofing membrane is engineered to handle temperature fluctuations by being flexible, resistant to thermal expansion and contraction, and capable of withstanding UV radiation. These properties ensure that the membrane remains intact and effective in protecting the underlying structure from water damage, regardless of the surrounding temperature conditions.

- Q: Can a waterproofing membrane be used for a commercial building?

- Yes, a waterproofing membrane can be used for a commercial building. Waterproofing membranes are specifically designed to protect structures from water damage. They are commonly used in various commercial applications such as roofs, basements, and foundation walls. The membrane acts as a barrier that prevents water from infiltrating the building, thus protecting it from potential leaks, moisture buildup, and mold growth. Additionally, waterproofing membranes are durable and can withstand harsh weather conditions, making them suitable for commercial buildings that are exposed to heavy rainfall or extreme temperatures. Overall, using a waterproofing membrane in a commercial building is an effective way to ensure long-term structural integrity and prevent costly water-related damage.

- Q: How does a waterproofing membrane handle exposure to UV rays and sunlight?

- A waterproofing membrane is designed to handle exposure to UV rays and sunlight through various mechanisms. Firstly, most waterproofing membranes are engineered with UV stabilizers and additives that help protect the material from the harmful effects of prolonged exposure to UV radiation. These stabilizers prevent the membrane from breaking down and deteriorating when exposed to sunlight. Additionally, many waterproofing membranes are manufactured with reflective pigments or coatings that help to reflect a significant portion of the sun's rays. This reflective property reduces the absorption of UV radiation, minimizing the amount of heat that is absorbed by the membrane. By reducing heat absorption, the membrane remains cooler, which helps to further enhance its durability and prolong its lifespan. Moreover, some waterproofing membranes are reinforced with materials such as fiberglass or polyester, which provide additional strength and resistance against UV rays. These reinforcement materials act as a barrier, shielding the membrane from direct exposure to sunlight and reducing the potential for sun damage. It is important to note that while waterproofing membranes are designed to withstand UV exposure, their performance can be affected by factors such as the intensity and duration of sunlight exposure, climate conditions, and maintenance practices. Regular inspections and maintenance, such as applying UV protective coatings or sealants, can help extend the life and performance of the waterproofing membrane in areas with high UV exposure. Overall, a well-designed and properly installed waterproofing membrane is engineered to handle exposure to UV rays and sunlight, ensuring long-term protection and durability for the underlying structure.

- Q: Can a waterproofing membrane be used for elevator shafts and stairwells?

- Elevator shafts and stairwells, being susceptible to moisture and water infiltration, can indeed benefit from the use of a waterproofing membrane. Particularly in below-grade or high-moisture environments, these areas are prone to such issues. The purpose of waterproofing membranes is to create a barrier that prevents water from penetrating and causing damage to the structure. When properly applied, a waterproofing membrane can effectively safeguard elevator shafts and stairwells, ensuring they remain dry and free from problems associated with water, such as mold growth, material deterioration, and structural damage. These membranes are typically constructed using durable materials like modified bitumen, PVC, or rubberized asphalt, which possess excellent waterproofing qualities. It is crucial to select a waterproofing membrane specifically designed for below-grade or high-moisture applications. These membranes should possess high resistance to hydrostatic pressure, the ability to bridge cracks, and long-term durability to withstand constant exposure to moisture. Moreover, it is important to have trained professionals with expertise in waterproofing systems handle the installation of the membrane in elevator shafts and stairwells. This will guarantee correct installation, resulting in an effective barrier against water infiltration. In conclusion, a waterproofing membrane is a suitable solution for elevator shafts and stairwells, providing effective protection against water penetration and related moisture issues.

- Q: Can a waterproofing membrane be used in conjunction with insulation materials?

- Using both insulation materials and a waterproofing membrane together is often recommended in order to protect buildings from moisture and improve energy efficiency. The waterproofing membrane acts as a barrier against water infiltration, while the insulation materials help regulate temperature and minimize heat loss or gain. By combining these components, the building envelope can effectively shield against water damage and maintain a comfortable indoor environment. Proper installation and compatibility between the waterproofing membrane and insulation materials are crucial for achieving optimal performance and long-lasting results.

- Q: Can waterproofing membranes be used on concrete slabs?

- Concrete slabs can indeed utilize waterproofing membranes. In fact, it is a widely adopted technique to shield concrete slabs from water harm. The purpose of waterproofing membranes is to establish a barrier that halts water infiltration into the concrete surface. This becomes particularly crucial for regions susceptible to moisture, like basements, balconies, or swimming pools. Through the application of a waterproofing membrane, the concrete slab effectively safeguards itself against water infiltration, which might otherwise trigger cracks, erosion, or the growth of mold. Moreover, these membranes have the added benefit of bolstering the overall longevity and durability of the concrete slab.

- Q: Can a waterproofing membrane be used in industrial facilities or warehouses?

- Yes, a waterproofing membrane can be used in industrial facilities or warehouses. Industrial facilities and warehouses often have concrete floors or walls that are susceptible to water damage from leaks or moisture. By applying a waterproofing membrane, these areas can be protected against water penetration, preventing potential damage to the structure and its contents. Waterproofing membranes are designed to create a barrier that prevents water from seeping through the surface, providing an effective solution for industrial facilities and warehouses where moisture control is essential. Additionally, these membranes are durable and can withstand heavy foot traffic and equipment, making them suitable for use in high-traffic areas. Overall, using a waterproofing membrane in industrial facilities or warehouses can help maintain a dry and safe environment, safeguarding the structure and its contents.

- Q: How does a waterproofing membrane handle expansion and contraction of a surface?

- A waterproofing membrane is specifically designed to accommodate the expansion and contraction of a surface. It is composed of flexible materials that can stretch and contract without compromising its integrity. This allows the membrane to move with the surface, preventing any cracks or damage that could lead to water infiltration. The membrane is typically installed with overlapping seams, creating a continuous barrier that can expand and contract as needed. These seams are often reinforced to provide additional strength and durability. Furthermore, the membrane is usually applied in multiple layers, which adds to its flexibility and ability to handle surface movement. In addition to the material composition, the installation process is crucial in ensuring the membrane can handle expansion and contraction. Properly trained professionals will consider the specific conditions of the surface, such as temperature fluctuations and structural movement, and install the membrane accordingly. They may use techniques such as hot-air welding or adhesive bonding to create a secure and flexible bond between the membrane and the surface. Overall, a waterproofing membrane is designed to accommodate the natural expansion and contraction of a surface. Its flexibility, reinforced seams, and multi-layer construction allow it to move with the surface without compromising its waterproofing capabilities, ensuring long-term protection against water infiltration.

Send your message to us

EPDM Self-adhesive Waterproof Membrane for Roof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords