EPDM Self-adhesive Waterproof Membrane for Green Rooftop

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

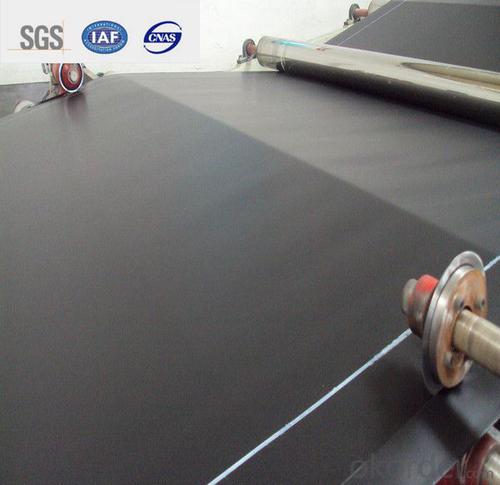

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

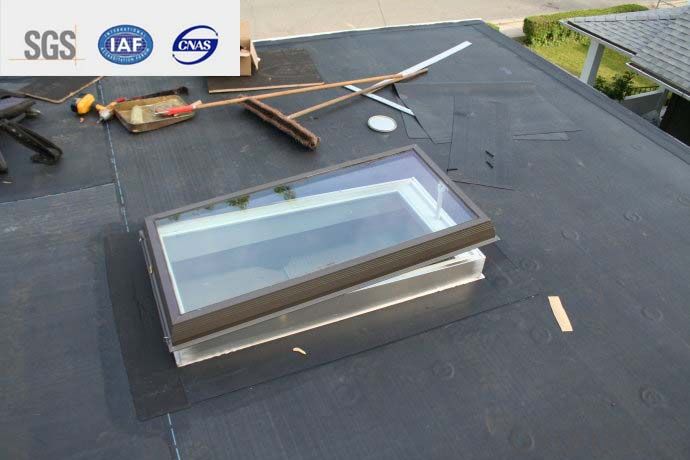

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Is a waterproofing membrane resistant to algae or moss growth?

- A waterproofing membrane is usually resistant to the growth of algae or moss. Its purpose is to form a barrier against water infiltration, preventing moisture from seeping into the underlying structure. These membranes are typically composed of materials that are not favorable for the growth of algae or moss, such as synthetic polymers or rubberized compounds. Furthermore, they are often treated with additives that hinder the growth of organic matter, including algae or moss. Nevertheless, it is crucial to acknowledge that if the membrane is consistently exposed to moisture or damp conditions over time, it may become a breeding ground for algae or moss. Therefore, it is important to regularly maintain and clean the waterproofing membrane to ensure its longevity and effectiveness.

- Q: Can a waterproofing membrane be used on parking garages?

- Yes, a waterproofing membrane can be used on parking garages. Waterproofing membranes are commonly used in parking garages to prevent water penetration and protect the structure from moisture damage. They can be applied to the roof, walls, and floors of the garage to create a barrier against water intrusion, helping to extend the lifespan of the parking structure and prevent costly repairs.

- Q: Can a waterproofing membrane be used for tunnels or subway systems?

- Yes, a waterproofing membrane can be used for tunnels or subway systems. It is a common practice to use waterproofing membranes in underground structures to prevent water infiltration and protect the structural integrity of the tunnels or subway systems. These membranes are designed to provide a barrier against water, ensuring the safety and longevity of the underground infrastructure.

- Q: Can a waterproofing membrane be used for a bridge deck?

- Yes, a waterproofing membrane can be used for a bridge deck. In fact, it is a common practice to apply a waterproofing membrane to bridge decks to protect the structure from moisture ingress, which can lead to corrosion and deterioration. A waterproofing membrane acts as a barrier to prevent water from seeping into the concrete deck, ensuring the longevity and durability of the bridge. Furthermore, it can also help to reduce the potential for freeze-thaw damage, which is especially important in areas with harsh weather conditions. Overall, using a waterproofing membrane for a bridge deck is a reliable solution to enhance its lifespan and maintain its structural integrity.

- Q: Can a waterproofing membrane be used on precast stainless steel surfaces?

- Yes, a waterproofing membrane can be used on precast stainless steel surfaces. Waterproofing membranes are designed to create a barrier against water penetration, regardless of the substrate material. The membrane can be applied directly to the stainless steel surface to provide protection against moisture, preventing leaks and potential damage. It is important to select a suitable waterproofing membrane that is compatible with stainless steel and has good adhesion properties. Additionally, proper surface preparation and application techniques should be followed to ensure optimal performance of the membrane.

- Q: Can a waterproofing membrane be used for a shopping mall underground parking?

- In a shopping mall underground parking, it is possible to use a waterproofing membrane. Due to their below-ground location, underground parking structures are at a high risk of water infiltration. To prevent this, a waterproofing membrane is typically installed during the construction process. This membrane acts as a barrier, stopping water from seeping into the parking structure and causing damage. It is designed to withstand the pressure from the surrounding soil and any potential hydrostatic forces. Moreover, a waterproofing membrane can also help reduce the risk of moisture-related issues like mold or mildew, which can compromise the safety and integrity of the parking structure. Therefore, incorporating a waterproofing membrane is a widely used and effective solution to ensure the long-term durability and functionality of underground parking facilities in shopping malls.

- Q: Can waterproofing membranes be used on plant rooms?

- Indeed, plant rooms can benefit from the utilization of waterproofing membranes. Within these rooms, one can typically find various apparatus and machinery that necessitate safeguarding against potential water harm. By implementing waterproofing membranes, a formidable defense is established to impede water infiltration, averting leaks and potential destruction to both the plant room and its contents. Typically, these membranes are administered to the walls, floors, and roofs of the plant room to ensure comprehensive waterproofing. Moreover, in addition to their water resistance, these membranes possess the ability to shield against other elements such as chemicals and fluctuations in temperature, rendering them an optimal solution for plant rooms.

- Q: Can a waterproofing membrane be used on aluminum surfaces?

- Indeed, aluminum surfaces can benefit from the application of a waterproofing membrane. Such membranes possess great versatility, enabling their use on a wide range of surfaces, including aluminum. Their purpose is to create a safeguarding barrier against water and moisture, effectively preventing any potential leaks or water-related harm. By employing a waterproofing membrane on aluminum surfaces, the material's longevity can be significantly extended as it remains protected from the detrimental effects of corrosion and rust, which are often triggered by water exposure. Nevertheless, it is imperative to carefully select a waterproofing membrane that is both compatible with aluminum and suitable for the specific application in order to achieve the most optimal outcomes.

- Q: How does a waterproofing membrane handle exposure to chemicals or solvents?

- Protection against water and moisture is the primary purpose of a waterproofing membrane. However, the membrane's ability to resist chemicals or solvents varies based on the type used. Various waterproofing membranes are available on the market, each possessing its own unique properties and capabilities. Certain membranes are specifically designed to withstand exposure to chemicals or solvents. These membranes are typically constructed using materials like PVC, TPO, or CPE. These materials offer exceptional chemical resistance, making them highly effective in environments where contact with chemicals or solvents is anticipated. In contrast, some waterproofing membranes may not possess the same level of resistance to chemicals or solvents. For example, membranes composed of bitumen or asphalt may experience degradation or damage when exposed to certain chemicals or solvents. In such cases, additional protective measures may be necessary, such as applying a chemical-resistant coating or implementing a secondary barrier to prevent direct contact between the membrane and the chemicals or solvents. When selecting a waterproofing membrane, it is crucial to consider the specific requirements of the project and the potential exposure to chemicals or solvents. Seeking guidance from a professional waterproofing contractor or manufacturer can help determine the most suitable membrane for the intended application. Regular inspections, maintenance, and proper cleaning of the membrane are also essential to ensure its longevity and performance when faced with chemicals or solvents.

- Q: Can a waterproofing membrane be used for historical buildings?

- Historical buildings can indeed benefit from the use of a waterproofing membrane. While it is vital to maintain the architectural integrity and historical significance of these structures, it is equally important to shield them from water damage. Waterproofing membranes offer an effective solution to prevent water infiltration, which can lead to decay or deterioration. These membranes can be applied to various surfaces, including roofs, walls, and foundations, without compromising the visual appeal of the historical building. It is essential to select a waterproofing membrane that is suitable for historical buildings, taking into account factors such as breathability, compatibility with existing materials, and adherence to preservation guidelines. By carefully choosing and correctly installing a waterproofing membrane, historical buildings can be safeguarded against moisture-related problems, ensuring their longevity and continued preservation.

Send your message to us

EPDM Self-adhesive Waterproof Membrane for Green Rooftop

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords