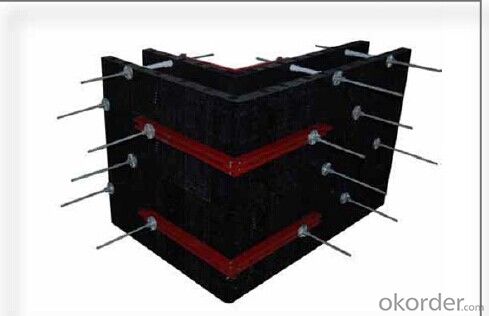

easy-set-up plastic formworks used in buildings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Cup-lock Scaffolding:

The biggest panel is 120x60cm, weight only 10.5kg, which can be lift and set up by only one person easily, need no crane on the site.

2. TheAdvantages of Cup-lock Scaffolding:

-easy set up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the

system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

-modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls

and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls120x60 panel (act size 120x60cm) of multiple by 5cm. The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

-strength

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

-enviroment friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment.

-consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

3. Images for Plastic formwork:

4. FAQ of Plastic concrete formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

- Q: What are the different types of formwork pins used with steel frame formwork systems?

- Formwork pins are essential components in steel frame formwork systems, serving to secure formwork panels and ensure stability while pouring concrete. Here are several types of formwork pins commonly utilized: 1. Wedge pins: The most widespread formwork pins, they possess a steel composition with a wedge-shaped end. By inserting the wedge into the formwork panel slot and using a hammer, the pin is driven into place. This wedging action tightly secures the formwork panels, effectively preventing movement during concrete pouring. 2. Straight pins: Similar to wedge pins, straight pins are also made of steel, but with a cylindrical shape. These pins are inserted into pre-drilled holes in the formwork panels and secured using a hammer. Straight pins are suitable when wedge pins cannot be easily inserted or when additional reinforcement is required. 3. Snap ties: This formwork pin type consists of a metal rod with a button-like head. The rod is inserted through the formwork panels, and the head is snapped into place, firmly securing the panels together. Snap ties are commonly employed in formwork systems that necessitate quick assembly and disassembly. 4. Coil ties: Coil ties serve as another formwork pin option for connecting formwork panels. They feature a metal rod with a spiral coil at one end. The coil is inserted into pre-drilled holes in the formwork panels, and the rod is twisted to tightly secure the panels. Coil ties provide a robust and secure connection between the formwork panels. 5. Flat ties: Utilized specifically in wall formwork systems, flat ties secure formwork panels in a flat orientation. These pins consist of a metal rod with a flat plate-like head. By inserting the rod through the formwork panels and twisting the head, the panels are securely fastened together. In summary, the diverse range of formwork pins employed in steel frame formwork systems offers various options to ensure secure and stable connections between formwork panels during concrete pouring.

- Q: How does steel frame formwork handle the placement of retaining walls and earthworks within the concrete structure?

- Steel frame formwork is a versatile and efficient method for handling the placement of retaining walls and earthworks within a concrete structure. This type of formwork uses steel frames that are easily adjustable and can be customized to fit the specific requirements of the project. When it comes to retaining walls, steel frame formwork provides a strong and durable support system. The steel frames are designed to withstand the pressure exerted by the soil and provide stability during the pouring and curing of the concrete. This ensures that the retaining wall will be able to withstand the lateral forces and maintain its shape and integrity over time. In addition, steel frame formwork allows for flexibility in the design and construction of retaining walls. The frames can be easily adjusted to accommodate different heights and slopes, allowing for the creation of walls with varying degrees of incline. This is particularly beneficial in situations where the retaining wall needs to be constructed on uneven terrain or where there are specific architectural or engineering requirements. When it comes to earthworks, steel frame formwork provides a secure and stable platform for placing the concrete. The frames are designed to support the weight of the concrete and provide a level surface for pouring and spreading the material. This ensures that the concrete is evenly distributed and properly compacted, resulting in a strong and durable structure. Furthermore, steel frame formwork allows for efficient and cost-effective construction of earthworks. The frames can be easily assembled and disassembled, making them ideal for projects that require frequent repositioning or where time is a critical factor. Additionally, the steel frames can be reused multiple times, reducing the need for excessive materials and minimizing waste. Overall, steel frame formwork is a reliable and efficient method for handling the placement of retaining walls and earthworks within a concrete structure. Its strength, flexibility, and cost-effectiveness make it a preferred choice for many construction projects.

- Q: What are the different types of coatings available for steel frame formwork?

- Steel frame formwork has several coatings available, each with their own unique properties and advantages. These coatings are designed to protect the formwork from corrosion, improve durability, and enhance overall performance. 1. Galvanizing, or zinc coating, is commonly used and provides excellent corrosion resistance by creating a protective layer on the steel surface. It is highly durable and suitable for both indoor and outdoor applications. 2. Epoxy coatings are known for their high chemical resistance and durability. They are applied in multiple layers to create a strong barrier against corrosion, chemicals, and abrasion. These coatings also adhere well to the steel surface for long-lasting protection. 3. Polyurethane coatings are resistant to weathering and UV radiation. They offer a flexible protective layer that can withstand extreme temperatures and mechanical stress. These coatings also provide good chemical resistance and are commonly used in demanding environments. 4. Powder coating is a popular choice due to its aesthetic appeal and durability. A dry powder is applied to the steel surface and then heated to form a protective coating. Powder coatings come in a variety of colors and finishes, making them suitable for architectural purposes. 5. Paint coatings are the most common and cost-effective option. They come in different types, such as acrylic, alkyd, and epoxy paints. While they may not offer the same level of corrosion resistance, proper surface preparation and maintenance can ensure long-lasting protection. When choosing a coating for steel frame formwork, it is important to consider the specific project requirements, including the environment, exposure to chemicals or moisture, and aesthetic considerations. Consulting with a coating specialist or professional engineer can help determine the most suitable coating type for specific applications.

- Q: How does steel frame formwork prevent concrete spilling or overflowing during pouring?

- To prevent concrete from spilling or overflowing during pouring, steel frame formwork is utilized. This formwork consists of steel panels or sheets that act as a barrier, preventing the concrete from flowing out of the intended area. These panels are securely connected to create a tight seal around the formwork perimeter, eliminating any potential leakage or seepage. To ensure stability and prevent deformation or collapse, the steel frame formwork is reinforced with robust support structures like steel beams or braces. These reinforcements not only contain the concrete but also withstand the weight and pressure exerted by it. Moreover, internal bracing and tie rods are often incorporated into the steel frame formwork to provide additional support and stability. These elements ensure that the formwork remains intact and firmly holds the concrete, minimizing the risk of any movement or displacement that could lead to spillage or overflow. In summary, steel frame formwork is an effective solution for preventing concrete spilling or overflowing during pouring. Its rigid structure, tight seal, and reinforced support guarantee that the concrete remains within the desired area, facilitating a controlled and successful pouring process.

- Q: How is the quality of the concrete surface achieved with steel frame formwork?

- The use of steel frame formwork results in a high-quality concrete surface for several reasons. Firstly, the rigid and stable structure of steel frame formwork ensures that the fresh concrete is evenly poured and compacted, preventing any irregularities or deformations. Additionally, the design of steel frame formwork includes adjustable elements like clamps, tie rods, and spacers, which allow for precise alignment and leveling. This guarantees that the concrete is poured at the correct thickness and with consistent dimensions, resulting in a smooth and uniform surface. Furthermore, steel frame formwork often incorporates form liners or surface treatments that can create decorative patterns or textures on the concrete. These liners or treatments can be easily attached to the steel frames, enabling the creation of aesthetically pleasing finishes. Moreover, the durability and reusability of steel frame formwork are advantageous, especially in large construction projects. The ability to reuse the same formwork multiple times without compromising the quality of the concrete surface ensures uniformity throughout the project. In conclusion, the use of steel frame formwork ensures a high-quality concrete surface due to its stability, adjustability, and durability. These factors contribute to the creation of a smooth, even, and aesthetically pleasing surface that meets all required standards and specifications.

- Q: Can steel frame formwork be used for both above-ground and below-ground concrete elements?

- Steel frame formwork is capable of being used for both above-ground and below-ground concrete elements. Renowned for its durability and strength, it is well-suited for diverse construction tasks. For above-ground elements like walls, columns, and beams, it serves as a means of support and shaping as the concrete cures. Additionally, the steel frame can withstand the pressure exerted by the wet concrete. When it comes to below-ground elements such as basements and foundations, steel frame formwork remains a feasible option. The inherent strength and rigidity of steel enable it to endure the pressure of the surrounding soil and groundwater, ensuring the stability and integrity of the structure. Moreover, steel formwork can be easily customized to accommodate intricate shapes and designs, rendering it suitable for a myriad of below-ground applications. In conclusion, steel frame formwork is a versatile solution that can be employed for both above-ground and below-ground concrete elements. Its strength, durability, and adaptability have established it as a favored choice in the construction industry for shaping and supporting concrete structures.

- Q: Can steel frame formwork be used for the construction of healthcare facilities?

- Yes, steel frame formwork can be used for the construction of healthcare facilities. Steel frame formwork is a versatile and durable construction technique that is commonly used in various building projects, including healthcare facilities. This formwork system consists of steel frames, which are designed to support the weight of the concrete and other construction materials during the pouring and curing process. There are several advantages to using steel frame formwork in the construction of healthcare facilities. Firstly, steel is a strong and rigid material that can withstand heavy loads, making it suitable for large-scale construction projects. Secondly, steel formwork is highly durable and can be used multiple times, reducing the overall construction costs. Additionally, steel frame formwork provides a smooth and even surface finish, which is essential for the construction of healthcare facilities that require sanitary and hygienic conditions. Moreover, steel frame formwork allows for efficient construction processes, as it is easy to assemble and disassemble. This saves time and labor costs during the construction phase. Additionally, the flexibility of steel formwork allows for customization and adaptability to meet specific design requirements of healthcare facilities. It is important to note that the use of steel frame formwork for healthcare facilities should comply with the relevant building codes and regulations. Proper engineering and design considerations must be taken into account to ensure the structural integrity and safety of the building. In conclusion, steel frame formwork is a suitable construction method for healthcare facilities. Its strength, durability, and flexibility make it an ideal choice for constructing buildings that require high standards of hygiene and functionality.

- Q: How is the steel frame formwork secured to the ground?

- Securing the steel frame formwork to the ground involves various methods. Among them, ground anchors or stakes are commonly used. These anchors are driven into the ground and attached to the formwork, providing stability and preventing any shifting or movement during the concrete pouring and curing process. Furthermore, tie rods or braces can be utilized to further secure the formwork. These rods or braces connect the formwork to nearby structures or anchor points, ensuring its firm placement. The choice of securing method for the steel frame formwork depends on the project's requirements and the soil conditions at the construction site.

- Q: Can steel frame formwork be used in areas with limited natural light?

- Yes, steel frame formwork can be used in areas with limited natural light. Steel frame formwork is designed to provide support and structure during the construction process. It is not dependent on natural light for its functionality. Therefore, it can be used in areas with limited natural light by utilizing artificial lighting sources such as floodlights or construction site lighting to ensure proper visibility and safety during the construction process.

- Q: Does steel frame formwork require any special equipment for installation and removal?

- Special equipment is needed for the installation and removal of steel frame formwork. Cranes or hoists are often necessary to lift and position the steel frames. In addition, specialized tools like wrenches and spanners may be necessary to tighten the bolts and ensure a secure connection between the frames. To remove the steel frame formwork, cranes or hoists are also necessary to safely lift and remove the frames from the structure. In conclusion, proper equipment is essential to ensure the efficient and safe installation and removal of steel frame formwork.

Send your message to us

easy-set-up plastic formworks used in buildings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords