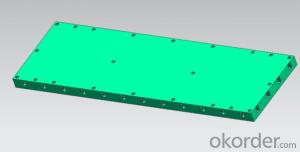

Easy Handling Plastic Formwork for House Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Waterproof Plastic PVC Foam Board Formworks Introduction

This kind of construction formwork can be special form like column and square.

They can be used in bridge, office building and roads construction.

Our products have characters such as energy conservation, environment-protection, and in low price. Another, turnovers can be up to 30 times, temperature adaptation range is wide. Plastic steel template can be any sizes so that it has wide adaptation.

easy installed and removed, sawed and drilled, and accessories complete.

save working hours more than 30% and increase efficiency more than 40%.

save construction template allocable cost over than 50%

Waterproof Plastic PVC Foam Board Formworks Feature

1. Life:turnover can be up to 40times

2. Tempreture condition:-20°C to 60°C

3. Feature:save 40%manhours and 50 %allocable cost

4. Convenient installation:be widely accepted by workers

5. Moldable size:size can be changed freely.

6. Resist compression:can support more than 5000 kilograms

7. Waterproof:100%

8. Useable widely used in building and construction

9. Energy saving,/environmental protection,/resource circulation

Waterproof Plastic PVC Foam Board Formworks Paramwter

Material: PVC | Structure: solid plate |

Cycle-index: 30 times above | Water content :0.3% |

Water thickness expansion rate: 0.1% | Static bending strength:21.9MPa |

Bending elastic modulus:1280MPa | Wear resistant surface(g/100r):0.08g/100r |

Condition after heating: no bubbles, no crack, no pitting | After heating the size change rate :0.20% |

Grip screws to board : 1470N | Grip screws to the edge of the board : 1070N |

Anti impact performance :14.1mm Impact toughness :64.8KJ/ m2 | High temperature repeated dimension change rate :0.12% |

Waterproof Plastic PVC Foam Board Formworks Specification

1, 15*915*1830(mm) 16.5Kg/pc±1Kg

2, 15*1220*1240(mm) 29Kg/pc±1Kg

3, Specifications can be customized

4, About 100M3 /T

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- The lower the density of the foam board is easier to deform.Crust foam can be changed to coextrusion foam. General cross-linking or blending halogenation and other methods to improve Vicat. Reduce traction override

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- It seems to have been the introduction of hollow plastic building template production line (foreign technology), the site last year to see someone used this plastic building template, our site is now using this plastic building template material is polypropylene PP, this template Cheap, suitable for ordinary wall. There is also a material that is made of polycarbonate PC This material is suitable for viaducts, water conservancy works, pouring walls without whitewashing. The wall is very light. It is expensive point.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- You do not explain your product is to open a metal mold or plastic mold, the two mold materials are not the same! I do plastic mold, we mainly use the factory S136 quenching material as a mold material, the slider generally use 718. And you also have the output of the product requirements of the mold, the production will choose a better point of the material.

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- Plastic mold is better, light weight, high impact strength, easy assembly, high turnover rate, smooth surface, no moisture, no mildew, Naisuan Jian, no cracking, large plate, less joints, can be saw, can Nail, can be processed into any length and so on

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- Both are their own strength, stiffness is not high, the turnover rate of the template material is low, but the cost is relatively low, due to different uses, can not be compared: wood sheet low cost, can be processed, the turnover rate is low, can not help blisters, if Small keel spacing is large, and the concrete side of the larger pressure, its own stiffness is low, there will be bending deformation or even up the mold, generally in the base floor or slope roof and other concrete appearance quality requirements are not high or one-time no longer a lot of turnover Parts of the use of plastic templates are generally stereotypes, such as ribbed floor in the plastic mold shell, is a specific structure with the template can be leased.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- This does exist. The reason is that the plastic building template in the cut and fixed convenience, significantly weaker than the wooden building template, and in the demolition process, due to the brittleness of plastic, but also easy to break, and the cost of plastic template is too high, so the site Are generally willing to use wooden building templates. If you want to improve the number of wood construction template use, that is, cost, it is recommended that you choose building templates within 30 strong business

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Low foaming high strength plastic building template. The template rigid plastic combination, high strength, light weight, impact strength, can be sawable nail can be welded, industrial temperature up to -15 ℃ to 75 ℃ can be applied without cracking. 10 meters high vertical drop does not break, can be used 40 times to 100 times, waste plate can be recycled, more than 30% of the cost savings than the wood template, is the twenty-first century to plastic and wood ideal plastic building template.

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- The support system of the building template should be able to maintain the safety and reliability of the vertical placement of the building template and its own stability under the wind load. The length of the foot adjustment bolt should meet the need to adjust the vertical installation of the template and adjust the self-stabilizing angle. The foot adjustment device should be easy to adjust and turn flexible. Panel should be used not less than 5mm thickness of the production of steel, the material should not be lower than the performance requirements of Q215A, the template of the ribs and back corure should use steel, cold-formed thin-walled steel production, material and steel panel material should be the same brand to ensure Welding performance and structural properties. Panel system, support system, operating platform system and connectors and other components. Composition of the building template The connection between the various systems must be safe and reliable.

Send your message to us

Easy Handling Plastic Formwork for House Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords