Double Suction Impeller Pump with High Quality Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

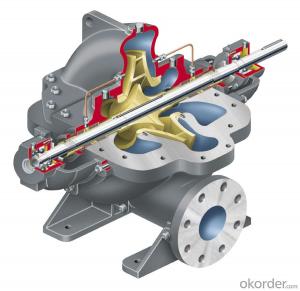

Double Suction Impeller Pump with High Quality

Application

Single Stage Double Suction Split Case Pump is used for conveying water or the physical and chemical properties similar to water and other liquids suitable for factories, mines, urban water supply, power stations, agricultural irrigation and water conservancy.

Characteristic

Compact structure,beautiful outline,stable operation,low noise;

Both inlet and outlet of this pump are placed under the axial line,so it is unnecessary to remove the inlet and outlet pipeline and motor;

The shaft seal of water pump has fine mechanical seal and soft stuffing seal,which can be selected according to different condition by user;

The impeller is static-balance calibrated,fixed on the shaft with round nut,and its axial position can be adjustedvia the round nut;

The pump is direct drived by motor via resilient coupling,it can be drived by internal combustion engine if it is necessary.

Technical Data

| Capacity | 50-20000m3/h |

| Head | 10-230m |

| Speed | 2900/1450/980/740/580/3500/1750/1180/890/710rpm |

Material

Casing: Cast iron/ ductile cast iron/cast steel/stainless steel/duplex stainless steel

Impeller: Cast iron/ ductile cast iron/brone/stainless steel/duplex stainless steel

Shaft:C-steel/stainless steel

The rotation direction

Viewed from motor, the direction of the pump is anti-clockwise,that is the suction in the left, the discharge in the right.

The rotating direction of the type pump is clockwise, that is the suction in the right, the discharge in the left.

Also can move the driver to another edge according to the user’s requires. Then, the rotating direction, the suction and discharge direction is in the opposite as the described above.

Photo

- Q: just changed the water pump on my lower unit installed the lower unit and started motor now there is no water coming out of the upper flow tube is it becouse the engine is not warmed up yet or is something not lined up ...........

- It shouldn't take long for the water to come out. Make sure the site tube isn't plugged up. If not, check your installation out.

- Q: This only happens while I am running water. I can hear the pressure switch clicking on and off the whole time I am doing dishes, laundry, ... Since it is only when the water is running I believe that means it is not a leak. I changed the check valve and that did not fix the problem. I checked the pressure in the tank and it seemed to be around the 20/40 mark. Any other ideas anyone?Thanks.

- It sounds like the bladder in your pressure tank has ruptured.

- Q: I am having water shortage problems and wonder if there is more I can do to maintain the health of my pump motor , pressure switch , and diaphram tank , if I run one outlet in or out of house , it only takes another spigot being used or a toilet flush to cause the system to run dry .I then have to reprime pump to have water or pump will run dry until it overheats ,

- This Site Might Help You. RE: Tips on proper maintenance on water well pump and service tank? I am having water shortage problems and wonder if there is more I can do to maintain the health of my pump motor , pressure switch , and diaphram tank , if I run one outlet in or out of house , it only takes another spigot being used or a toilet flush to cause the system to run dry .I then have to...

- Q: can a failing water pump sound like rattling or popcorn until the motor begins to over heat? the sound is nearthe waterpump. it goes away once the temp starts to overheat.the temp will get near redline then go down to normal and then start creeping up again. thanks for any replies.

- it sure can.

- Q: how often do i need to change a timing belt and water pump on my car? also, how much should it cost? should i have it done at the dealers or at a small mechanic shop if i chose to? which would be best? what are steps when having timing belt change?

- Not knowing the car and the market you live in... $3-500 is a good guess... Call the dealer and price them,sometimes they are so experienced doing a job they will quote less then an independent repair shop... Usually not though. As your friends for a referral. Bob

- Q: 2 pumps in parallel, lift the same, the pump head is not stacked; 2 pumps in series, the same flow, pump head is not superimposed?.

- 2 pumps parallel, lift the same, pump head is not stacked?;Answer: the head can not be superimposed, that is, a lift and a pump, but the pumping speed (flow) is two times a taiwan.2 pumps in series, the same flow, pump head is not stacked?.Answer: the head can be superimposed, that is, the pump head is two times as much as a pump, but the pump speed is the same as that of a pump.

- Q: Was able to remove all bolts except the one in the rear of engine one of the bigger bolts the pulley from the serpentine belt blocks itdoes the pulley need to be removed and if yes then how

- Sometimes there are holes in the pulley and you can rotate it until the hole gives you access to the bolt. If there are no such holes, then you will probably have to remove the pulley. The pulley may be fastened with one, four, or zero bolts. If there are bolts for the pulley, remove them and proceed with common sense and use a puller if necessary. If there are zero bolts holding the pulley to the water pump, then it is pressed on and you will need to remove it with a specialty tool called a pulley puller which you can get as a loaner or cheap rental at many auto parts stores. The pulley must also be reinstalled with a pulley installer, also available as a loaner or cheap rental. Are you replacing the water pump or just removing it to do other work? If you look at a new one and it doesn't come with a pulley on it, then you know that the pulley must be removed to go on the new pump no matter what.

- Q: The pond is 10' long x 2' wide x 1' deep. The pump is at one end and water is raised 1' to a buried garden hose that is maybe 12' long and then at the end it goes up 2' to release the water over some rocks. I had a 330 gph pump that worked well but died. That size has been discontinued. Go smaller or bigger? DON

- Hi Don, In my point of view it depend on the final effect that you want to create. If you are in the mood of water theraphy, mean that you like to the sound of the water fall, you may want to consider a pump size that a bit higher than your previous ones, and vice versa. In a nutshell you should be able to determine the effect of the waterfall you need since you already have your previous old pump running before.This should be your best guideline to check the size of your new pump needs. There is a bit of extra caution needed if you are thinking of using a bigger size of pump, you should ensure that the pump are not sucking to fast of the water. If this is the case you might be end up having your pond drain half tank. You can get the circle time for the water flow base on the pump size from the catalog.I'm sure your hardware guy are gladly assist you in understanding the matrix conversion Pond size over the pump size,since I can't explain in detail here about the graph reading. But in most cases I just relatively using the first option of comparing the old pump size with the new one. Hope that help. Fazla

- Q: I am creating a project where I must pump water to a helmet. If you have any ideas, thoughts, solutions, diagrams, etc. please? thanks

- your question is not clear, do you need to build the pump from scratch or you should find one? what is the water flow rate? how high the water need to go? what the helmet has to do with the problem? simplest solution will be to go to the store and buy small hand pump (for fuel).

- Q: the water pump from the factory has an extra hole coming out the side its the smaller one on the end of this pic.

- I would be a little hesitant on using an automotive water pump on a boat. The may seem similar however there are several key differences in the way they are made. excerpt from the below URL: In regard to the cooling systems, one of the major differences is found in the water-circulating pump. This is especially noticeable when you have a raw water cooled engine. Unlike their automotive counterpart, a marine pump works in an open cooling system. This type of system is extremely corrosive to the pump. Therefore, the pump must be altered for longevity. A marine pump has a special ceramic seal, stainless steel backing plate, and a bronze impeller to resist corrosion. An automotive style pump, with its stamped steel impeller, would fail due to corrosion in a short time. I have done this before, I boat in fresh water and my boat was raw water cooled, the pump was leaking after 2 seasons, wasn't worth the savings. The extra hole may have been for an optional closed loop cooling system on the boat or like was stated a heater or bypass line in a car.

Send your message to us

Double Suction Impeller Pump with High Quality Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords