Double Suction Centrifugal Water Pump for Farm Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Double Suction Centrifugal Water Pump for Farm Irrigation

1.Double Suction Centrifugal Water Pump for Farm Irrigation Description

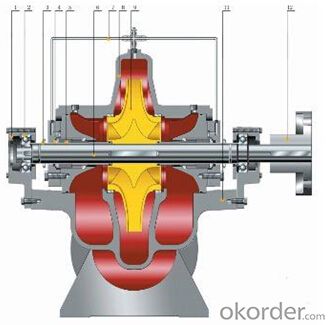

The Single Stage Double Suction Split Casing Centrifugal Pump is designed for Irrigation, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of Double Suction Centrifugal Water Pump for Farm Irrigation

•Attractive design

•High efficiency, steady performance

•Big capacity, medium pressure

•High concentricity of components

3.Double Suction Centrifugal Water Pump for Farm IrrigationSpecification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

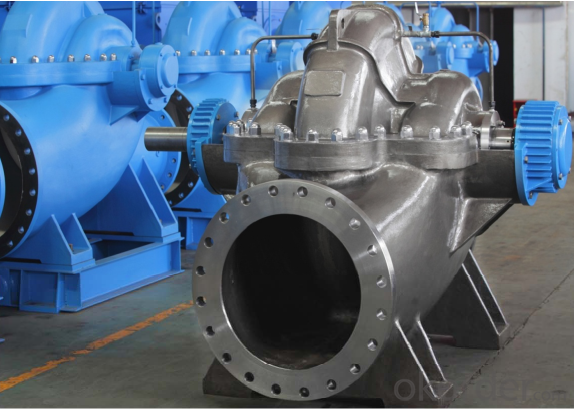

4.Picture of Double Suction Centrifugal Water Pump for Farm Irrigation

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q: I need information about basic water pumps. I'll have to build a mechanical one for school. Do you have any ideas, information, designs, links? Thanks!

- A very simple and old design for a water pump is called the ball-chain or bucket-chain pump. A google search should show you what they are. Building one should be fairly straightforward and simple.

- Q: How do you remove it without taking the engine out?

- Disconnect lower radiator hose (8286) from the water pump lower tube. Remove the engine mount nuts. Remove the cowl extension panel. Disconnect the water bypass hose and the heater hose from the water pump outlet tube. Remove the water pump outlet tube bolt and position the tube assembly out of the way. Install the lifting eye to the exhaust manifold (9430). Attach engine lifting equipment and raise the engine 127 mm (5 inches). Remove the bolt and the accessory belt idler pulley. Remove the bolts and the generator support bracket. Remove the four bolts and the water pump pulley (8509). Remove the water pump. Remove the five nuts. Remove the five studs. Remove the four bolts. Remove the water pump, lower tube and gasket as an assembly.

- Q: I have a Honda 20003 bf15 d short shaft Ineed to change the water pump I have removed the 5 bolts that hold the lower unit it on but the shifter is steal hooked up how doI unhook that?

- Please get the workshop manual. From an imperfect memory it should be in forward gear to expose a link - but I could be confusing it with other brands. This brand has a known issue with the water pump if ever run dry as both the impellor and the housing can be damaged instantly. The pump should always be replaced as a full assembly, housing, seals and impellor, as detritus can easily block water galleries and that requires extensive work to remediate. The thermostat should be checked and replaced at the same time. Worn and damaged impellor material can easily end up through the block, head, thermostat etc. and that must be checked for as well. The lower cylinder can be down on compression caused by local overheating due to this and mud, sand and corrosion reducing water flow. An engine that very much must be flushed and looked after after all use - that includes all the larger models with this brand. They are quite a good engine, but seem very heavy for the output to me - particularly compared to lifting a two stroke on and off....

- Q: Does anyone know or can show me a picture of the location of the water pump in the '97 Totota avalon please? I'm trying to replace mine.Please and Thank you :)

- The water pump is commonly driven either by the pump drive belt or the timing chain/belt. It is easy to replace the belt-driven water pump, as it can be remove from outside of the engine. For the timing chain/belt driven water pump, you need to remove the front cover and belts before you can reach the pump. Drive your car to the nearest dealer workshop and ask the mechanic.

- Q: I'm not familiar w/ this model but need to swap out the water pump. I have no pictures or publications. Anything in particular to watch out for? Is this a pushrod engine w/ a water pump mounted in the front center of the engine and driven by a serpentine belt? Thanks in advance.

- It's very easy to change. It's driven by a serpantine belt but it's off center Right up front closer to the radiator and on top. Break the 13mm pulley bolt's loose, remove the belt, remove loosened pulley bolts and pulley. Then there's like 6, 8mm bolts to remove the pump and that's it. You might have to remove the overflow tank to make it easier to get to. The pump is round and looks like it will go on any 'ol way but it doesn't. It only goes on one way.

- Q: motor overheats but no leak. water just boils in resorvoir. is it hard to do it on my own?

- Water pumps have whats called a weep hole, if it's going the weep hole will leak coolant, Could be the belt on the waterpump is not tight eneough to turn the pully.

- Q: Dear friends, please let me know in most of the power plants recirculation line and balance leak off lines are provided for boiler feed water pumps and those lines are connected to Deaerator. Why?

- The feed pumps for most power plants are multistage centrifugal pumps. They have a minimum flow requirement or the balancing forces of the various impellers are lost and the pump is damaged. A recirculation line permits a minimum flow to be maintained at all times. It goes back to the deaerator so the boiler feedwater is not lost. Note: many of these pumps have the recycle automated so it is only in operation at very low flow rates. The leak off from the balancing line is recycled for the same reason.

- Q: i have little leak from water pump need to replace it in my mazda 6 2006 v6 3.0l. i have little over 120.000 miles on it. Any body know how much it may cost me?

- I don't know why, but the water pump costs between $125 and $160. That seems a little high. It probably retails for $186. Under normal conditions, you just get things out of the way, unbolt the old pump, clean it up and put the new one in. The problem is the other stuff that gets in the way. I'm just estimating the job will take 5-8 hours. Just multiply times the labor rate in your area. Don't forget the anti-freeze when you're done.

- Q: I have a 2000 chevy impala with 85K on it. I have heard/a weird rattle noise from under the hood for some time now. I once asked about it on here and got suggestions regarding front end problems. I had that checked out and the front end is good. I still have the rattle noise along with a high pitched, but not very loud, squeeling noise when I accelerate. I am leaking coolant and it seems to be coming from near one of the belts. Is this a bad water pump? If so how expensive of a fix is it and how involved of a repair is it?

- It sounds like a water pump or maybe a loose connection. It is probably time for a water pump if it hasn't been replaced yet. Parts will run under $60 and it probably involves an hour of labor. The Impala is a big car, it shouldn't be hard to get to and remove. Taking it to a shop will run under $100-$150 for everything.

- Q: Horizontal pumps, vertical pumps, which kind of expensive?

- Relatively speaking, the horizontal is expensive, because there is a horizontal chassis, if there is a large pump case, the best selection of horizontal, otherwise the weight of the motor to the pump body smashed!

Send your message to us

Double Suction Centrifugal Water Pump for Farm Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords