Swing Check Valve Wafer Type Double Disc Body Material CF8C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

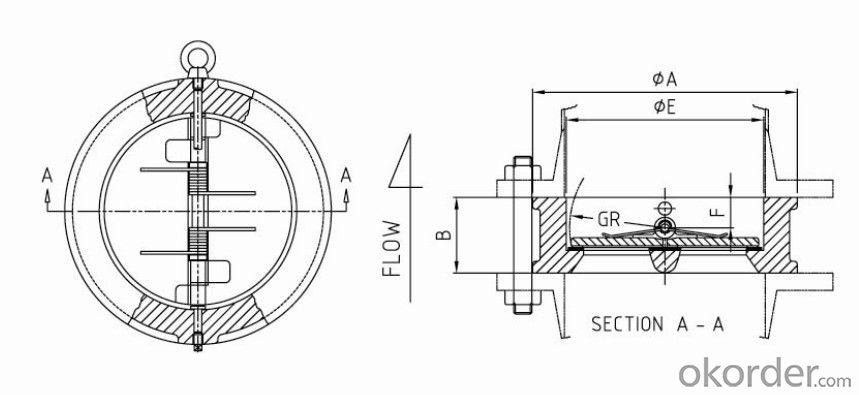

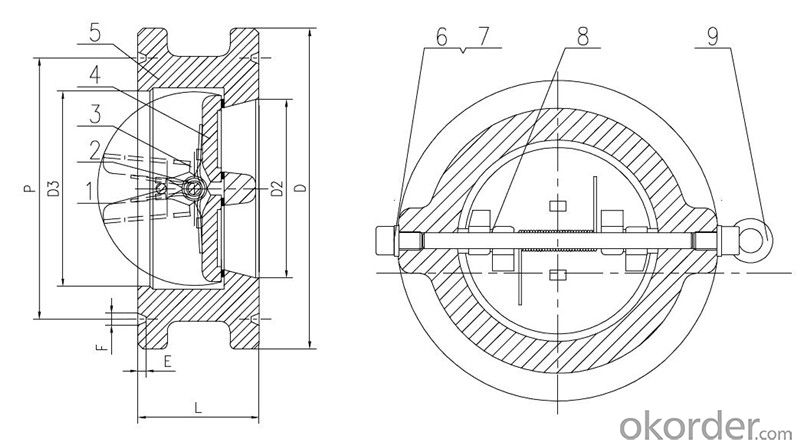

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: i need to know the setting of the valve and a little advice on the up and down of the valves

- As Bob said, you had probably best bite the financial bullet and get someone experienced to do it. With the bucket over shim designs, the shim you need to change is underneath the bucket, the device that rides against the camshaft. To change the shims, you have to remove the camshafts and when you replace them, you must get them timed exactly right or else you can have pistons hitting valves..not good at all. They put the shim under the bucket to keep the cam from spitting the shims out through the valve cover at high rpms. The older 2 valve 900-1000-1100-1300 Kaws have shim over bucket and can be changed with a special $20 tool, a little screwdriver and small magnet . However, you might consider getting a shop manual and checking the valve clearance yourself. If all are within specs, then there is no need to take it to a shop. My old KZ1000 went something like 110,000 miles and only need two shims changed in all that time, so your bike could very well be ok.

- Q: Im trying to replace the egr valve on a 97 lincoln continental. I need to find out what size wrench I need, to get the nut off. Do you know?

- I am assuming you want to replace the EGR valve because you are getting an insufficient EGR flow trouble code. Before you replace a perfectly good valve with an inferior aftermarket part that will likely fix nothing, a little more diagnosis is in order. If you have access to a scan tool and a vacuum gauge, perform a KOER (key on engine running) test on the engine with the vacuum gauge connected to the hose to the EGR valve. When self-test reaches the EGR test, look for the vacuum guage to move during the self test. If it moves, the vacuum source and EGR solenoid are good. If not, trace the vacuum harness for leaks. Without the scanner and vacuum gauge, find a length of hose and suck on the hose, or connect to other vacuum source to test the valve. You are looking for an RPM drop at idle when you open the valve in this way. I suspect your problem is a passageway clogged with carbon. Remove the valve and throttle body to access the clogged areas and manually decarbonize. This is the most common reason for an insufficient EGR flow on a Lincoln, along with a faulty DPFE sensor or related hoses. My money is on the clogged passages or the bad DPFE sensor.

- Q: i have a leak on the front of that valve cover and the oil is going down to the headers,,how can i fix the problem.?how do i install da gasket do i need any special things??thanx for tha help

- He could have placed helicoils in to repair that. without the splendid torque the pinnacle will warp and this could actual reason the oil leak.in fact ask him why he did no longer restoration it whilst it became aside. The regulation probable calls so you might furnish him of undertaking to repair it as quickly as.you may no longer could pay for that and you may ask to work out the gaskets he would be removing to interchange returned. If he takes it aside and reuses the gaskets he purely put in there will be issues down the line.

- Q: large veins contain one way valves, which keep the blood flowing in one direction. why dont large arteries need similar valves?

- The aorta and the pulmonary artery both start at valves from the heart, but I don't know if you could say they have valves. A lot of arterial flow is regulated by smooth muscles which constrict to direct flow to other areas. These are a kind of valve too.

- Q: Compare and contrast stenosis and regurgitation (insufficiency) in terms of the functional abnormality associated with the valve leaflets and their effects on hemodynamic parameters such as stroke volume.

- stenosis means thats it difficult to open the valve to allow a full ejection of blood. regurgitation is caused by an insufficient valve, in which the valve does not close all the way, and thus allows blood to flow backwards. For instance, the two AV valves (mitral on the left, tricuspid on the right), are prevented from prolapsing by chordae tendonae, which are connective tissue fibers attached to pieces of cardiac muscle (papillary muscles) on one end, and the edge of the valve on the other. If these chordae tendonae break, this may cause blood to flow back into the respective atria during ventricular systole. Valvular insufficiency and prolapse will cause diminished stroke volume. Valvular stenosis, on the other hand, is typically caused by a buildup of material on a valve which inhibits its movement. This buildup could be many different things, to name a few: valve calcification due to hypercalcemia, bacterial adhesion and growth due to sepsis, plaque (cholesterol bound with free radicals) buildup on the valve, a fibroma, etc... If the valve's opening is inhibited, and it does not open all the way, there will be a diminished blood flow into whatever chamber is next in the sequence. If an AV valve is stenotic, the ventricles may not fill properly, and preload will be low, which will lower ejection volume. If the semilunar valves are stenotic, then the ventricles will likely hypertrophy because they will need to work harder to force as much blood out, because blood entering the ventricle must equal blood leaving the ventricle with each heartbeat (starlings law of the heart).

- Q: Our water heater (bought in 2007 so still fairly new still under warranty luckily) seems to release water from the pressure release valve quite frequently. Everyone seems to say that it shouldn't do it often and ours probably does it a couple times per day. 2 main questions - 1. Is there really a risk of too much pressure building up and the water heater exploding (that's what the sales guy at Lowe's said) and 2. Any idea what the problem might be/what we should check out?

- The valve is called a TP valve. It stands for Temperature and Pressure relief valve. If either the temp or pressure goes over the set amount, the valve opens and releases water. This is a safety feature to prevent the unit from exploding. You may have the temperature set too high on the heater. The valve may be bad and can be replaced for under $15 and 15 minutes work. The valve operates with a spring and sometimes it can fail. On the valve is a plate that tells how much pressure and temperature is needed to operate it.

- Q: i have been having these chest pains and i went to the doc. they did an ekg, blood test for enzymes and a echo. Well today i went back for the results of the echo and was told that i had a leaky valve but it was nothing to worry about and that there are just trace amounts of valve regurgitation. Im only 19 and i have no other history of heart problems or diseases should i be worried...they said i didn't need any anti biotics or anything and that it wouldn't kill me just to watch for it as i age into my latter years of life 50-70, but im still kinda worried..anyone else have this? im also pregnant and im concerned as to how this will affect my pregnancy, labor and delivery????

- i have the same problem,they found it when i was 40 and that's been 10 yrs ago.in 10 yrs it has put me in the hospital 4 times.but feel good most of the time.good luck.

- Q: i was told my egr valve needs to be replaced, so im wondering if the system cleaner will help at all. thanx

- unlikely. A EGR pulls unburnt gases out of your exhaust and recycles them into your intake. Gumout may well be burned interior your cylinders to get rid of carbon deposits in the block and not lots if any may well be waiting to get recycled on your EGR. you may eliminate your EGR and soak it in carburetor purifier in one day to loosen the deposits and then use a mild brush to get the obdurate airborne dirt and dirt out. be careful while soaking the valve nonetheless, the (i do no longer understand the technical term) rubber areas on the interior may well be broken by ability of carb purifier so attempt to soak as lots of the metallic areas as you may in it and shop that rubber area dry. $40 5 isn't undesirable for a clean valve by ability of ways. a clean one in my truck is over $a hundred and thats seen much less costly by ability of a few.

- Q: I have a problem with standing water that keeps puddling up and never drains under where my valves are located for my sprinklers. What do I do? Should I just put 3/4 drain rock on top? Please help?

- Sounds to me, like you have one of two things happening. Either you have a leak, which needs to be fixed. Or the valve box is in a low area where the water drains to... Turn on the water and watch the valves.. you might be able to see where the water is coming from. It may be as simple as tightening down the valve screws, or you may need to turn off the water at the main and repair or replace it. If the water is draining there or the leak isn't all that terrible the only way drain rock would help is if you were to dig underneath the valve a little, and to replace what you dig out with rock... Just make sure you can still access everything when you are finished. Good Luck!

- Q: What exactly is a flow valve for an ice maker on a refrigerator? Any idea what it would cost to replace it? Is it easy to replace?

- google repairing flow valve on ice maker it is there.

Send your message to us

Swing Check Valve Wafer Type Double Disc Body Material CF8C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords