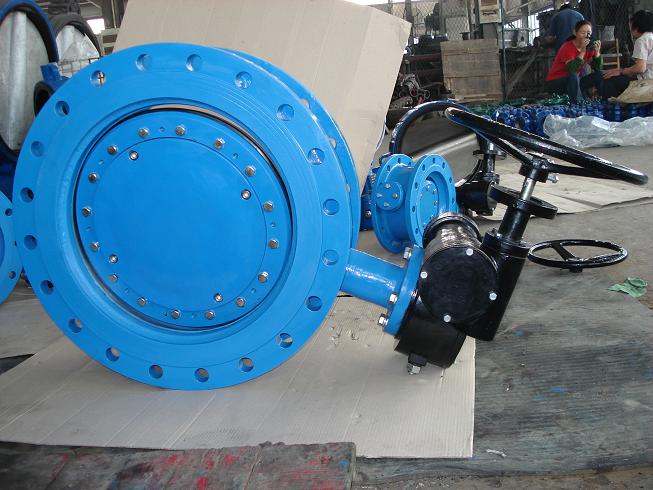

Double flanged Metal Seal eccentric butterfly valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Double flanged Double Eccentric Butterfly Valve

PN10/16/25

DN100 ~ DN2000

Technical Specifications

- Design and manufacture: EN593, EN1074-1 and 2

- Face to face dimension: EN558-1 Series 14 (DIN3202 F4)

EN558-1 Series 13 (BS5163)

- Flange dimensions and drillling: EN1092-2 PN10/16/25

- Size range: DN100 - DN2000

- Max. working pressure: 1.0/1.6/2.5 MPa

- Inspection test: EN12266

- Working temperature: -15°C to +80°C

- Suitable medium: water

Main Fetures

- Double eccentric disc reduces seal wear and torque

- Body seat ring is welded directly on the body

- Bi-directional flow and low head loss

- Disc sealing ring to be replaceable on pipeline without dismantling the valve

- Body and disc inside and outside epoxy powder coated (min. 250 microns)

- Opening and closing indicators are provided

- Coupling flange for electric actuator in compliance with ISO5211

- Gearbox and electric actuator operation available

Main Parts and Materials

Body and disc: ductile iron EN GJS500-7/400-15

Shafts: stainless steel AISI 420

Body seat ring: stainless steel AISI 304

Disc sealing ring: EPDM or NBR

Retaining ring: stainless steel or ductile iron

Shaft bearing: Du bushes (self lubricating bushes)

- Q: people tell me i need to install new valves and valve guides

- Maybe you simply need to re-adjust your valves? Or buy a Lancer.

- Q: My question mainly pertains to Electric Motor-driven Motor Operated Valve Actuators.

- The motor drives a gear operator on the valve and is limited in the degree to which it operates by a set of limit switches so it doesn't over run or over torqued the shaft. This arrangement typically also has another set of limit switches that indicate the open or closed position so the person controlling the valve will know its position. This type of operator is typically used on ball, butterfly or plug valves but can be used on gate valves.

- Q: If I flush the toilet the drama begins. While the toilet is flushing, if I lift the lift of the lid of the tank cover NOT THE SEAT, water shoots up straight in the air from the top/cap of the fill valve. This is a picture of a toilet fill valve.

- The okorder . Type in toilet fill valve in the search box and click on SEARCH. You will see a list of How-To videos that will help you with this project.

- Q: Also, Is a pneumatic control valve an ATC or an ATO; is it a FO or FC valve?

- THere are a large number of types of valves; ball, gate, globe, needle, etfc. I suggest you look up valves on wikipedia. ATO = air to open; the valve has a pneumatic operator with a spring returning it to closed when the air pressure is removed ATC is the reverse FO = fail open; if the actuator fails the valve will be open. Actuators are made ATO, ATC, and air to move either way [no spring]. The latter would be your FLP. Control valves, by which I mean a proportioning valve or valve with a variable open area, with a 3-15 psi control input, are usually ATO.

- Q: My grandfather is going in for a valve replacement.. and I'm really worried about him.. I just want some information.. any good websites if you have them.. I looked on google.. But if you have any good ones that would be great..No horrible comments please..

- Please see the webpages for more details on Heart valve surgery, Mitral regurgitation, Aortic stenosis, Aortic insufficiency and Artificial heart valve. There are four main valves in the heart. Mitral valve connecting left auricle and left ventricle. Aortic valve situates in the left ventricle at the beginning of the aorta, the main artery of the human body. Tricupid valve connecting right auricle and right ventricle. Pulmonary valve situates in the right ventricle at the beginning of the pulmonary artery carrying the impure blood to the lungs. (1) The valves may adhere together, causing a narrowing of the valve opening and obstruction to the flow of blood. This is usually known as stenosis of the valve. (2) Because of the loss of elasticity and distortion of the valve the latter may not close proerly, so that a leakage or regurgitation of blood results.This is known as incompetence of the valve. Chronic rheumatic valvular disease may affect all the valves of the heart but the most commonly damaged are the mitral and aortic valves. Mitral stenosis and aortic incompetence are the conditions which most commonly arise, although mitral incompetence and aortic stenosis also occur. Quite often, mitral stenosis and aortic incompetence develop in the same person.

- Q: I have a lawn tractor with a 10 hp Tecumseh and its running so rich because of the carburetor float valve not seating. So how should I fix this?

- A disfunctional float valve will cause the carburetor to flood from fuel spilling over the top of the float bowl. The float valve acts like a toilet valve and just fills the float bowl up to the top and closes until the level drops from the fuel evaporation being pulled off while running. I don't know the exact specs, but you should be able to guesstimate and adjust by bending the float tang, or just replace the float valve.

- Q: Okay, so veins have valves to help counteract the pull of gravity. I'm wondering, do the veins in the head have this same adaptation, seeing as these veins are simply bringing blood down to the heart, and are not pulling against gravity.

- no they dont have valves

- Q: I am having a leaky valve is that normal? the doctor said that it is normal what do i do?

- Like most everything, there are degrees of valvular leakage. A valve can be leaking a lot or a very little amount. Valves are a biologic mechanism and therefore are not precisely manufactured with some areas that don't ideally fit, leading to minor leakage. If you were to take 100 random people off of the street and do an echocardiogram, the vast majority would have one valve or the other that had at least some trivial leakage. Therefore if the majority of people have the same thing and it is not a pathological process, it is essentially normal. Next, certain valves leaking are much more important that other valves. Moderate leakage of the tricuspid valve for instance is not a particularly important finding. But moderate leakage of the aortic valve is a very big deal that requires close medical attention. In sum, valves with trivial leakage do not require serial exams for follow up or any special measures like antibiotics before dental procedures. Since this is such a common finding, it is reasonable to consider this a normal finding. Not knowing precisely what the result was on your echo, I can not specifically advise you. At your next doctor's appointment make a note for yourself to ask him/her for clarification. Good luck.

- Q: Where is the mixer valve on a '94 Dodge Caravan with a 3.0 V6 engine?

- if it is a fuel injected vehicle and i'm pretty sure it is. It is a computer controled system you have to take it in to get adjusted.

- Q: .The valve behind the toilet is spewing water (we have connected a hose to it and have it emptying into the tub). When we try to shut the water off from that valve, the knob or turny-thingy (the name escapes me right now) just turns and turns correcting the water flow slightly, but not shutting it off.The problem it that we can't find the main water valve outside the house. What am I looking for please?!? Also, we shut a valve off in the garage, but it was for the hot water.Help!

- find the house water meter located a the edge of the street in your yard and turn the main valve off

Send your message to us

Double flanged Metal Seal eccentric butterfly valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords