Dental Floss Available Wholesale OEM Individually Floss Mint Waxed 50yds

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

Brand: OEM/Ok Floss

Floss material:TPFE

Floss length:50m/OEM

Wax:Import germany wax/american wax/bee wax/candelilla wax/customized wax

Flavor:Mint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss: original color

Floss original color:Individual bulk PP box/as customized

Applications:Family,Hotel,Travel,Supermarket

Delivery:By sea,By air,By express.

Lead time:20-30days

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots

where your toothbrush can’t reach, generally between your teeth and under the gumline.

FAQ

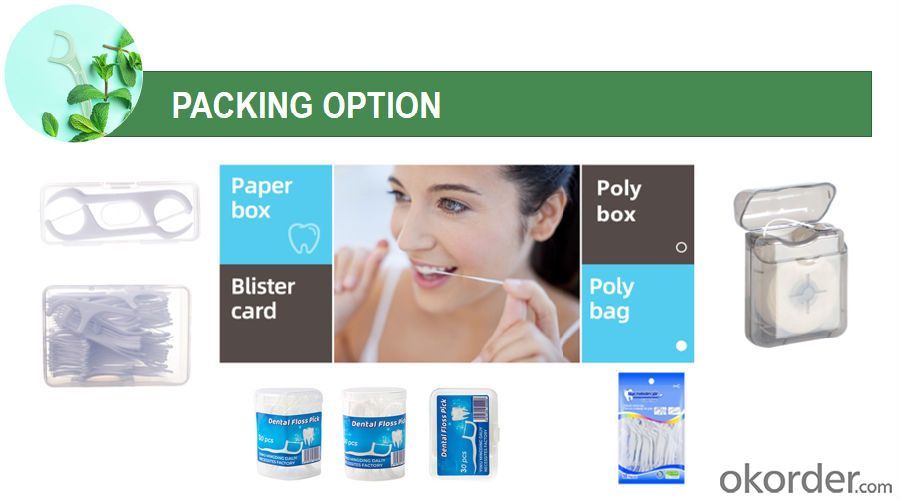

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

- Q: What are the considerations for ensuring the durability and longevity of medical plastic products?

- Some considerations for ensuring the durability and longevity of medical plastic products include selecting high-quality materials that are resistant to wear and tear, ensuring proper manufacturing processes that promote structural integrity, conducting thorough testing and quality control measures, implementing proper storage and handling procedures, and providing regular maintenance and cleaning guidelines to ensure the products remain in optimal condition. Additionally, considering factors such as temperature, humidity, and exposure to chemicals or sterilization methods can also contribute to the longevity of medical plastic products.

- Q: Glaucous, black plastic frame glasses frame how to get rid of?

- You can scrub it with detergent and rinse it with plenty of water.

- Q: Can medical plastic be safely used in pediatric patients?

- Yes, medical plastic can be safely used in pediatric patients.

- Q: Can plastic products be scrubbed with medical alcohol?

- You can use banana water, absolute alcohol and gasoline:1, according to the proportion of 1:1:1, you can completely erase all dirt, including plastic surface layer, remember not to use too much effort to wipe again and again;2, according to the proportion of 1:2:2, moderate cleaning power;Use should pay attention to, do not get the wound, mouth, eyes, so as not to bring harm, at the same time pay attention to fire prevention

- Q: What are the considerations for preventing the migration of additives from medical plastic?

- There are several key considerations for preventing the migration of additives from medical plastic. Firstly, it is important to carefully select and test the additives used, ensuring they meet regulatory requirements and are compatible with the intended application. Additionally, the manufacturing process must be closely monitored and controlled to prevent contamination or degradation of the plastic. Proper storage conditions and packaging materials should also be considered to minimize the risk of migration. Regular testing and quality control measures should be implemented to ensure the safety and efficacy of the medical plastic.

- Q: What are the most common uses of medical plastics in radiography?

- Medical plastics are commonly used in radiography for various purposes such as manufacturing X-ray cassettes, protective shields, patient positioning devices, radiation attenuation materials, and disposable accessories like syringes and tubing. These plastics provide excellent durability, flexibility, and radiolucency, making them essential components in ensuring patient safety, image quality, and efficient healthcare delivery in radiology departments.

- Q: How do medical plastics contribute to the field of sports medicine?

- Medical plastics play a crucial role in the field of sports medicine by providing innovative solutions for the prevention, treatment, and rehabilitation of sports-related injuries. These plastics are used to manufacture various medical devices, such as braces, splints, and prosthetics, which offer support, stability, and protection to athletes during their recovery process. Additionally, medical plastics enable the development of lightweight and flexible equipment, such as protective gear and orthopedic implants, enhancing athletes' performance while minimizing the risk of further injuries. Overall, medical plastics contribute significantly to sports medicine by promoting faster healing, improving athletes' safety, and facilitating their return to the game.

- Q: What are the considerations for using medical plastic in bioelectronics?

- When considering the use of medical plastic in bioelectronics, several factors need to be taken into account. Firstly, biocompatibility is crucial to ensure that the plastic does not cause any adverse reactions or harm to the body's tissues or cells. Additionally, the plastic should have suitable electrical properties, such as being insulating or conductive, depending on the specific application within bioelectronics. It is also important to consider the durability and long-term stability of the plastic, as it may be exposed to various environmental conditions and mechanical stress. Finally, the manufacturing process and cost-effectiveness of the medical plastic should be evaluated to ensure its feasibility for large-scale production in the field of bioelectronics.

- Q: How do medical plastics impact the manufacturing process of medical devices?

- Medical plastics have a significant impact on the manufacturing process of medical devices. These specialized plastics offer numerous advantages such as biocompatibility, durability, and flexibility, making them ideal for various medical applications. Medical plastics enable the creation of complex and intricate designs, allowing manufacturers to produce intricate components and devices that meet specific medical requirements. These plastics can be easily molded, reducing production time and costs. Additionally, medical plastics possess excellent chemical resistance, preventing degradation and preserving the sterility of medical devices. Overall, medical plastics play a crucial role in enhancing the efficiency, functionality, and safety of the manufacturing process for medical devices.

- Q: How can plastics be removed by sticking them to glass?

- With banana water. Is used to remove paint an industrial agent, it is very easy to buy (sell paint there is a place to sell)

Send your message to us

Dental Floss Available Wholesale OEM Individually Floss Mint Waxed 50yds

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches