Converter Continuous Casting Square Steel Billet Q235 Q275 Q345 for Construction

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Converter Continuous Casting Square Steel Billet Q235 Q275 Q345 for Construction

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

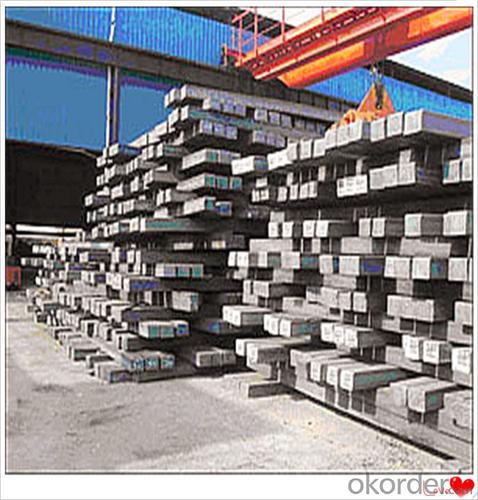

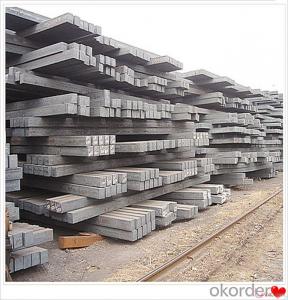

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How do steel billets contribute to the construction of bridges and infrastructure?

- The strength, versatility, and durability of steel billets make them crucial in the construction of bridges and infrastructure. These cylindrical bars of steel are created through a process known as casting, where molten steel is poured into molds and allowed to cool and solidify. A primary benefit of steel billets in bridge construction is their ability to bear heavy loads. Bridges face substantial weights from vehicles, pedestrians, and natural forces like wind and earthquakes. Steel billets, with their remarkable strength and structural integrity, provide the necessary support to withstand these loads and ensure the bridge's safety and stability. Additionally, steel billets offer flexibility in design and construction. Their malleability allows for easy shaping and forming into various structural components, such as beams, columns, and girders, which are vital in bridge construction. This flexibility empowers engineers to create innovative designs and optimize material usage, resulting in cost-effective and efficient bridge structures. Another significant advantage of steel billets is their resistance to corrosion. Bridges endure harsh environmental conditions, including moisture, saltwater, and pollution. Steel billets can be treated with protective coatings or alloyed with elements like chromium or nickel to enhance their corrosion resistance. This guarantees the bridge's longevity and durability, reducing maintenance costs and extending its lifespan. Moreover, steel billets contribute to the speed of bridge construction. As they are prefabricated in steel mills, they can be produced in large quantities and transported to the construction site, ready for assembly. This prefabrication process minimizes on-site construction time, reducing traffic disruption and shortening the overall project duration. In conclusion, steel billets are essential in the construction of bridges and infrastructure due to their high load-bearing capacity, flexibility in design and construction, resistance to corrosion, and ability to expedite construction. Their contribution ensures the safety, longevity, and efficiency of bridge structures, making them a vital component in the development of robust and reliable infrastructure systems.

- Q: How are steel billets used in the production of mining conveyors?

- Steel billets are used in the production of mining conveyors as they serve as the raw material for manufacturing various components such as frames, supports, and conveyor belts. These billets are heated, shaped, and machined to create the required parts that are strong, durable, and capable of withstanding the harsh conditions of the mining environment.

- Q: 100Q235 steel can only be rolled from billets of Q235?Or a billet can be rolled into Q195~Q215 and other models of steel?Is there a detailed classification of billets? Do you have GB?

- Billet classification of GB, it is convenient to check

- Q: Can steel billets be customized according to specific requirements?

- Certainly, specific requirements can be taken into account when customizing steel billets. Steel billets, which are semi-finished products typically used for further processing in the production of various steel products like bars, rods, and wire, can be tailored to meet different applications by adjusting their dimensions, chemical composition, and mechanical properties. When it comes to customization, steel billets can be modified in terms of their size and shape. To ensure optimal efficiency during subsequent processing, the length, width, and thickness of the billets can be altered depending on the requirements. Furthermore, the shape of the billets can be customized to match the desired end product, be it square, round, or rectangular. Moreover, the chemical composition of steel billets can be adjusted to achieve specific properties. By altering the percentage of elements like carbon, manganese, and alloying elements such as chromium or nickel, the steel can be tailored to exhibit certain characteristics, including increased strength, improved corrosion resistance, or enhanced weldability. Lastly, the mechanical properties of steel billets can be customized through heat treatment processes. Techniques like quenching and tempering can be applied to control the hardness, toughness, and overall strength of the steel, making it suitable for specific applications. In conclusion, steel billets can be customized in terms of size, shape, chemical composition, and mechanical properties to meet specific requirements. This ensures their effective utilization across various industries and applications.

- Q: What are the main challenges in the marketing of steel billets?

- The main challenges in the marketing of steel billets can be attributed to several factors. Firstly, one of the major challenges is the highly competitive nature of the steel industry. There are numerous steel manufacturers and suppliers globally, which creates a saturated market. This leads to a constant struggle for market share, as companies need to differentiate themselves from their competitors and maintain a strong presence. Secondly, fluctuations in global demand and supply of steel can pose significant challenges. Steel billets are primarily used as raw material for various industries, including construction, automotive, and manufacturing. Any changes in these industries' demand can directly impact the demand for steel billets. Therefore, marketing strategies need to be adaptable and responsive to market dynamics to ensure a stable customer base. Additionally, pricing is another critical challenge. Steel billets are often subject to price volatility due to factors such as raw material costs, energy prices, and global economic conditions. Companies must constantly monitor and analyze these factors to set competitive prices while maintaining profitability. Moreover, the marketing of steel billets requires a thorough understanding of the target market's needs and preferences. Different industries may require specific qualities and specifications in their billets, such as size, composition, or surface finish. Companies must invest in research and development to meet these requirements and effectively communicate the advantages of their products to potential customers. Another challenge lies in establishing and maintaining strong relationships with customers. Steel billets are typically sold through long-term contracts and relationships built on trust and reliability. Building and nurturing these relationships require consistent quality, on-time delivery, and excellent customer service. Lastly, environmental sustainability is an emerging challenge in the marketing of steel billets. With increasing environmental regulations and growing consumer awareness, companies need to position themselves as environmentally responsible and promote sustainable practices throughout their value chain. In conclusion, the marketing of steel billets faces challenges related to intense competition, demand-supply dynamics, pricing, market understanding, customer relationships, and environmental sustainability. Overcoming these challenges requires strategic planning, continuous adaptation, and a customer-centric approach.

- Q: What are the different types of steel billet shearing techniques?

- There are several types of steel billet shearing techniques, including guillotine shearing, rotary shearing, and flying shear.

- Q: How are steel billets tested for strength and durability?

- To ensure the strength and durability of steel billets, rigorous examinations and tests are conducted. The objective is to verify that the billets possess the necessary properties to withstand their intended application and perform optimally in diverse conditions. The tensile strength test is a key evaluation performed on steel billets. This involves gradually increasing the axial load on the billet until it reaches its breaking point. By measuring the applied force and resulting deformation, the ultimate tensile strength can be determined. This test assesses the steel's ability to resist external forces and provides vital information about its structural integrity. Another crucial assessment is the hardness test, which measures the steel billet's resistance to indentation or scratching. Various methods, such as the Brinell, Rockwell, or Vickers hardness tests, can be used to determine the hardness value. This information helps evaluate the billet's resistance to wear, deformation, and potential damage. Heat treatment is also vital in testing the strength and durability of steel billets. This process involves controlled heating and cooling cycles to modify the billets' microstructure, resulting in improved mechanical properties. By carefully monitoring temperature, time, and cooling rate during heat treatment, desired properties like increased strength and toughness can be achieved. Furthermore, non-destructive testing techniques, like ultrasonic testing, magnetic particle inspection, and radiographic examination, are employed to assess internal quality and identify any potential defects or flaws in the billets. These methods provide valuable information about the billet's structural soundness, ensuring it meets required standards and specifications. Additionally, chemical composition analysis is conducted to verify the elemental composition of the steel billets. This analysis ensures that the alloying elements are within specified limits, as they significantly affect mechanical properties. Any deviation from the required composition could compromise strength and durability. In conclusion, steel billets undergo a comprehensive series of tests and evaluations to ensure strength and durability. These include tensile strength testing, hardness testing, heat treatment, non-destructive testing, and chemical composition analysis. By subjecting the billets to these assessments, manufacturers can guarantee the quality of their steel products, ensuring they meet the demanding requirements of various applications.

- Q: What are the properties of steel billets?

- Steel billets are semi-finished products that are typically rectangular in shape and serve as the starting point for the production of various steel products. They possess several distinct properties, including: 1. High strength: Steel billets have exceptional strength due to the presence of carbon and other alloying elements. This enables them to withstand heavy loads and provide structural integrity in various applications. 2. Ductility: Steel billets can be easily deformed without fracturing, making them highly ductile. This property allows for the shaping and forming of the billets into different products through processes such as rolling, forging, and extrusion. 3. Thermal conductivity: Steel billets have good thermal conductivity, meaning they can efficiently transfer heat. This property is particularly useful in applications that involve heat treatment or require heat dissipation, such as in the manufacturing of automotive parts or machinery. 4. Corrosion resistance: Steel billets can exhibit a certain level of corrosion resistance depending on their composition and surface treatment. However, they are generally prone to rusting if not properly protected, so additional measures like coatings or galvanization may be necessary. 5. Machinability: Steel billets are known for their machinability, which refers to their ability to be easily cut, drilled, or milled into desired shapes and sizes. This property makes them suitable for a wide range of machining operations, facilitating the production of intricate parts and components. 6. Recyclability: Steel billets are highly recyclable due to the inherent recyclability of steel as a material. This property not only reduces waste and environmental impact but also contributes to the sustainability of steel production. Overall, the properties of steel billets make them an essential and versatile material in various industries, including construction, automotive, machinery, and manufacturing.

- Q: What are the main factors affecting the machinability of steel billets?

- The main factors affecting the machinability of steel billets include the composition of the steel, its hardness, the presence of impurities or inclusions, the grain size and structure, as well as the cutting tool material and geometry.

- Q: What is the average production cost of steel billets?

- The average production cost of steel billets can vary depending on various factors such as the location, production scale, raw material costs, energy costs, labor costs, and other operational expenses. However, on a general basis, the average production cost of steel billets can range between $400 to $600 per metric ton. It is important to note that the production cost can fluctuate based on market conditions and the state of the global steel industry. Additionally, factors like technological advancements, efficiency measures, and economies of scale can also influence the production cost of steel billets. It is advisable for companies or individuals looking for accurate and up-to-date information on the average production cost of steel billets to consult industry reports, market analysts, or relevant trade associations. These sources can provide more specific and detailed data tailored to a particular region or market segment.

Send your message to us

Converter Continuous Casting Square Steel Billet Q235 Q275 Q345 for Construction

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords