Colored Powder Coated Aluminum Window Extrusions Profiles - Aluminum Sheets Colorado

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Colored Powder Coated Aluminum Window Extrusions Profiles Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Colored Powder Coated Aluminum Window Extrusions Profiles:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

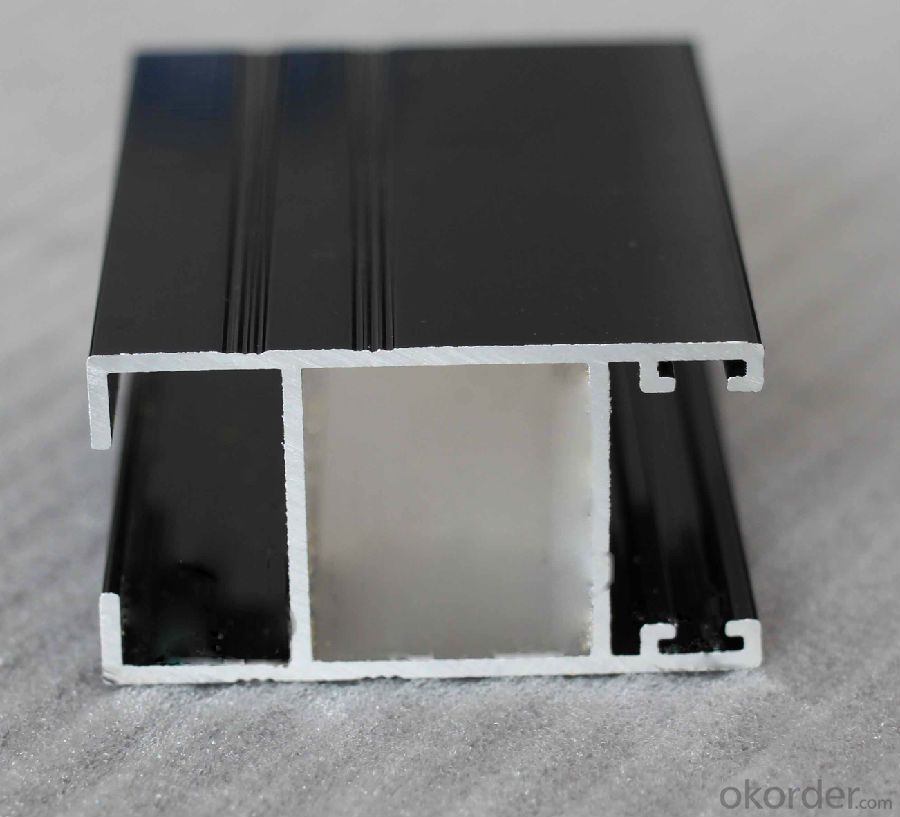

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

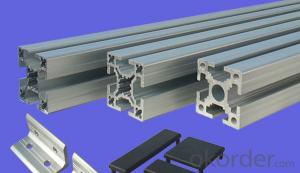

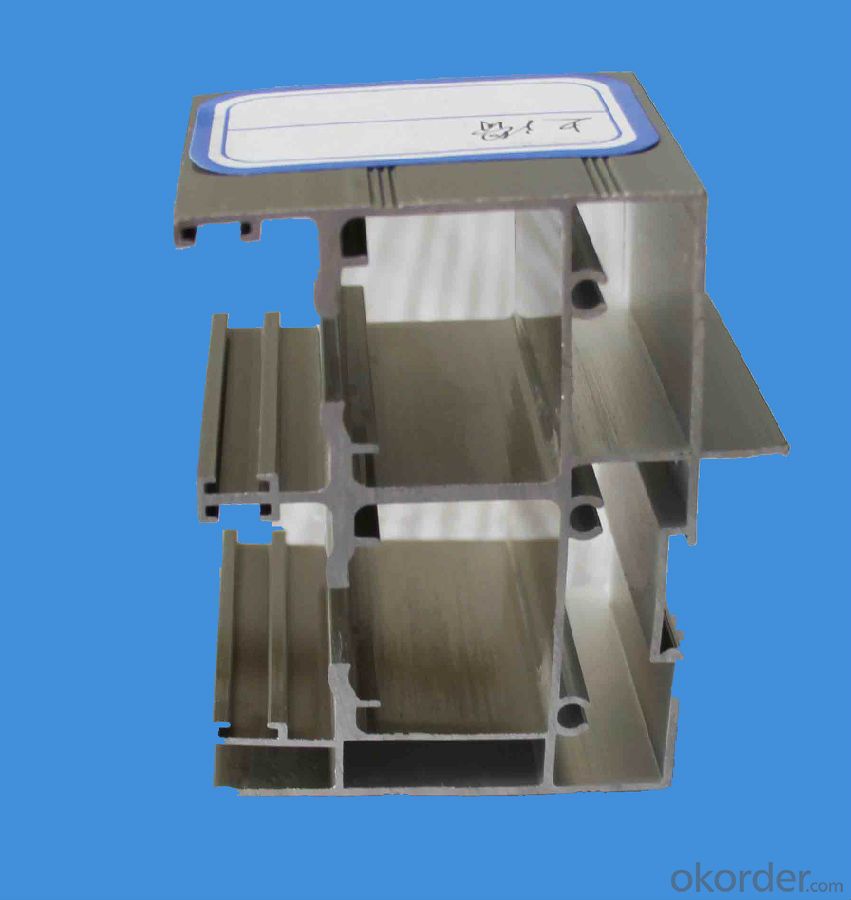

Images of the Colored Powder Coated Aluminum Window Extrusions Profiles:

Colored Powder Coated Aluminum Window Extrusions Profiles Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Are aluminum sheets available in different colors?

- Aluminum sheets come in various colors, catering to different aesthetic preferences and design needs. These sheets can be coated or painted with a range of shades. The color choices span from classic metallic finishes such as silver and gold to an extensive selection of modern and vibrant colors. This wide availability of colors enables aluminum sheets to be utilized in various applications like architectural cladding, signage, automotive industry, and home décor. Moreover, the color coating or paint on these sheets not only enhances their durability but also offers added protection against corrosion.

- Q: Can 101 aluminum sheets be used in the production of musical instruments?

- Yes, 101 aluminum sheets can be used in the production of musical instruments. Aluminum is a lightweight and durable metal that is commonly used in the manufacturing of various musical instruments. It offers good resonating properties and can produce a bright and clear sound. Additionally, aluminum is highly malleable, allowing it to be easily shaped and formed into different components of musical instruments such as bodies, frames, or keys. Therefore, 101 aluminum sheets can certainly be utilized in the production of musical instruments, contributing to their overall quality and performance.

- Q: A 0.250-g sample of a magnesium-aluminum alloy dissolves completely in an excess of HCl (aq). When the liberated H2 is collected over water at 29 C and 752 torr, the volume is found to be 311 mL. The vapor pressure of water at 29 C is 30.0 torr. What is the mass percentage of aluminum in this alloy?

- P_H2 = 0.950 atm (Dalton's Law of partial pressures) n=Pv/RT = (0.950 atm)(0.311 L) / (0.08206 (L*atm)/(mol*K))(302.15 K) n_H2 = 0.011915983 mol Balanced equations: Al + 3HCl -- 3/2H2 + AlCl3 Mg + 2HCl -- H2 + MgCl2 By these equations, we know that every mole of Al will give us 1.5 moles of H2, and every mole of Mg will give 1 mole of H2. We can therefore set up an equation for the mass of Al like this: *Let a = the mass of MAGNESIUM* Al = 0.250 g - a With this equation in mind, we can setup two equations solving for 'n' of each element by dividing by its molar mass and multiplying by the molar ratio: n_Mg = a / 24.30 (1:1 ratio, so we don't have to multiply) -- number of moles of H2 produced by the reaction of Mg (now written as n_H') = a / 24.30 n_Al = (0.250 g - a) / (26.98 g/mol) Because of the molar ratio shown above, we must multiply n_Al by 1.5 in order to get n_H2 produced by the reaction of aluminum, hereafter known as n_H2 Since we know the number of moles produced by the sum of the reactions, we can add these equations together and solve for n_H2. (**note that your value will be different because you have a different volume**) Set up the equation like this: n_H2' + n_H2 = n_H2 = 0.011915983 mol Sub in your individual equations for n_H2' and n_H2: (a/24.3) + 1.5[(0.250-a)/26.98] = 0.011915983 mol Rearrange and solve for a (mass of MAGNESIUM): (26.98a + 9.1125 - 36.45a) / (24.3)(26.98) = 0.011915983 0.011915983 = 9.47a a = 0.137298281 g Once you have your 'a' value, divide it by the total mass (0.250 g) and multiply by 100%. This gives you the percentage of Mg. (0.137298281 g / 0.250 g) * 100% = 54.9193 % Since you want ALUMINUM, you must subtract the percentage of Mg from 100. 100 - 54.9193 = 45.08% So, the mass percentage of aluminum is 45.08%. I hope this is helpful!

- Q: I get to do an aluminum blank for a fence and I am curious whether I can put slots in it with the router?I am not sure how thick it is, may say 3/16's.

- Yes you can use a router on aluminium. Use some kind of a fence, a piece of angle iron or a block of hardwood. Use a new bit, an old dull one will cause you problems. Pre-drill smaller holes than the slot width at each end of the slot. Stay back away from the end of the slot about 1/32 of an inch. Make several passes, at a depth of about 1/16 of an inch, per pass. If you can, make the slot with a bit smaller than the finished slot width. Use a 3/16 bit for a 1/4 inch slot. Use a 5/16 bit for a 3/8 inch slot. This will give cleaner slot edges and allow you to accurately make the slot width that you want. You can do this dry, but a little WD-40 oil will give even cleaner slot edges. Also climb mill the last pass on each slot edge to give a better/ smother edge. Climb Milling is pushing the router backwards of the way you normally travel in wood. Ben

- Q: What are the effects of utilizing aluminum sheets on the environment?

- <p>The environmental impact of using aluminum sheets includes both positive and negative aspects. On the positive side, aluminum is recyclable, and its use in construction and manufacturing can reduce the need for more energy-intensive materials like steel. However, the production process of aluminum is energy-intensive and generates greenhouse gases, contributing to climate change. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Despite these concerns, aluminum's lightweight nature can reduce energy consumption in transportation, and its durability can extend the lifespan of products, reducing waste. Overall, the environmental impact depends on the balance between these factors and the specific context of use.</p>

- Q: Are aluminum sheets suitable for food storage applications?

- Indeed, food storage applications can make good use of aluminum sheets. The food industry widely employs aluminum due to its lightweight nature, durability, and impressive thermal conductivity characteristics. It is common to fashion food storage containers, foil wrap, and trays from aluminum sheets. These sheets effectively shield against moisture, oxygen, and light, thereby preserving the freshness and quality of food. Moreover, aluminum is non-toxic and remains unaffected by acidic or alkaline foods, guaranteeing the integrity and safety of the stored food's taste.

- Q: Can aluminum sheets be anodized with custom designs?

- Yes, aluminum sheets can be anodized with custom designs. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, and this layer can be dyed or printed with custom designs before sealing, allowing for personalized and decorative finishes on aluminum sheets.

- Q: This question asks for the duration aluminum sheets can last and how their lifespan compares to other materials.

- <p>The lifespan of aluminum sheets can vary depending on the environment and usage, but generally, they can last for several decades with proper care and maintenance. Aluminum's resistance to corrosion and weathering makes it a durable choice. Compared to other materials, aluminum is more durable than wood and many plastics, but it may not last as long as some high-quality stainless steels or certain types of stone. It's also lighter than steel, making it a popular choice for construction and manufacturing applications where weight is a concern.</p>

- Q: How do aluminum sheets compare to steel sheets in terms of strength?

- Aluminum sheets and steel sheets differ in terms of strength. Steel is generally stronger than aluminum, as it has a higher tensile strength, meaning it can withstand greater forces without breaking or deforming. Steel sheets are commonly used in applications that require high strength and durability, such as construction, automotive manufacturing, and aerospace. On the other hand, aluminum sheets offer a good balance between strength and weight. While aluminum is not as strong as steel, it is significantly lighter, which makes it advantageous in certain applications where weight reduction is a priority, such as the manufacturing of aircraft and vehicles. Additionally, aluminum sheets have excellent corrosion resistance, making them suitable for outdoor or marine environments. Ultimately, the choice between aluminum and steel sheets depends on the specific requirements of the application, considering factors like strength, weight, durability, and corrosion resistance.

- Q: Alumina is the protective coating that covers aluminum when exposed to oxygen. It's actually corroded aluminum that prevents the aluminum from continuously corroding.What I didn't know until recently was that alumina is an electrical insulator. If that's the case why then isn't aluminum an insulator if one is trying to pass current along its surface?

- Aluminum is an efficient conductor of electricity. A usual fabric that is not conductive is glass but glass will habits heat. Wood isn't warmth conductive or an electricity conductor however has a low combustion factor. You probably have a specific utility you are watching for then you definitely'd better ask extra certain questions.

Send your message to us

Colored Powder Coated Aluminum Window Extrusions Profiles - Aluminum Sheets Colorado

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords