Aluminum Sheets Colorado Springs for Color Coated Window Glass Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

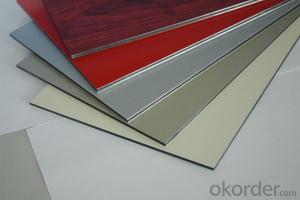

1.Structure of Aluminium Coils for Color Coated Window Glass Decoration

Aluminium Coils for Color Coated Window Glass Decoration is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA3104 is one of the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Color Coated Window Glass Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminium Coils for Color Coated Window Glass Decoration

4. Product Specification of Aluminium Coils for Color Coated Window Glass Decoration

| Alloy | Temper | Thickness | Width | Weight |

| AA1100 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ of Aluminium Coils for Color Coated Window Glass Decoration

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum sheets suitable for outdoor uses like fences or signs?

- <p>Yes, aluminum sheets are commonly used for outdoor applications such as fences and signage. Aluminum is lightweight, durable, and resistant to corrosion, making it ideal for outdoor conditions. It can withstand various weather elements without rusting. Additionally, aluminum can be easily formed into different shapes and sizes, and it's available in a wide range of colors and finishes, which makes it versatile for both functional and aesthetic purposes in outdoor settings.</p>

- Q: What is the tensile strength of aluminum?

- The tensile strength of aluminum can differ depending on the specific alloy and temper, as well as the manufacturing process. However, the average range of aluminum's tensile strength is approximately 70 to 700 MPa (megapascals). This puts aluminum in the category of relatively strong materials when compared to other non-ferrous metals. It should be noted that factors such as the thickness and shape of the aluminum component, as well as any heat treatment it has undergone, can also impact its tensile strength. Therefore, it is always advisable to refer to specific data sheets or engineering references for precise and accurate information regarding the tensile strength of a particular aluminum alloy.

- Q: How do you ensure the dimensional accuracy of aluminum sheets?

- To achieve the desired dimensional accuracy of aluminum sheets, several actions can be taken: 1. Utilize Advanced Manufacturing Techniques: Employing state-of-the-art equipment and methodologies in the production of aluminum sheets is crucial for ensuring precise dimensions. This entails utilizing reliable and calibrated machinery to accurately cut, roll, and shape the sheets according to the specified requirements. 2. Implement a Comprehensive Quality Control System: Establishing a robust quality control system is essential for upholding dimensional accuracy. This entails conducting regular inspections and measurements at different stages of the manufacturing process to identify any deviations from the required dimensions. Precision measuring instruments, such as calipers, micrometers, or laser scanning devices, can be employed to accomplish this. 3. Opt for High-Quality Materials: The choice of aluminum material significantly impacts dimensional accuracy. Using high-quality aluminum with consistent properties and minimal impurities guarantees that the sheets maintain their desired dimensions throughout the manufacturing process. 4. Control Temperature: Temperature fluctuations can affect the dimensional accuracy of aluminum sheets due to expansion or contraction. Maintaining a controlled temperature environment during manufacturing helps mitigate these effects and ensures that the sheets retain their intended dimensions. 5. Handle and Store Properly: Exercising caution in the handling and storage of aluminum sheets is crucial to prevent any deformations or damages that could impact their dimensions. This involves utilizing appropriate lifting equipment, avoiding excessive bending or twisting, and storing the sheets in a controlled environment to shield them from moisture or extreme temperatures. 6. Regularly Calibrate Measuring Instruments: Regular calibration of measuring instruments used in the dimensional inspection process is vital. This practice ensures accurate measurements and eliminates any potential errors that may arise from instrument drift or wear. By adhering to these measures, manufacturers can minimize dimensional variations and uphold the desired accuracy of aluminum sheets, thereby meeting the specific requirements of various industries such as automotive, aerospace, construction, and electronics.

- Q: What is the surface finish of 101 aluminum sheets?

- The surface finish of 101 aluminum sheets can vary depending on the manufacturing process and desired application. Common surface finishes for 101 aluminum sheets include mill finish, brushed finish, and polished finish.

- Q: What are the different surface finishes for aluminum sheets in the construction industry?

- The construction industry presents various options for surface finishes on aluminum sheets. These finishes aim to improve the appearance and durability of the aluminum, making it suitable for diverse construction applications. One prevalent surface finish for aluminum sheets is the mill finish. This finish refers to the raw, untreated surface of the aluminum, which may exhibit minor imperfections or scratches. Mill finish finds common use in applications where appearance is not a significant concern, such as structural components or industrial projects. Another well-liked surface finish is the anodized finish. Anodizing involves an electrochemical process that forms a protective layer on the aluminum's surface, enhancing its resistance to corrosion and wear. Anodized finishes come in various colors, allowing for greater design flexibility in construction projects. They are commonly employed for architectural elements like window frames, facades, and decorative panels. Painted finishes are also frequently employed in the construction industry. Aluminum sheets can be coated with a layer of paint, providing aesthetic appeal and additional protection against corrosion. Painted finishes can be customized to meet specific design requirements, making them suitable for a wide range of construction applications. Additionally, brushed finishes find extensive use in the construction industry. Brushing is a mechanical process that creates a textured surface on the aluminum, resulting in a unique, matte appearance. This finish is commonly utilized for decorative purposes, such as interior wall panels or furniture in commercial spaces. In conclusion, the construction industry offers a range of surface finishes for aluminum sheets, including mill finish, anodized finish, painted finish, and brushed finish. Each finish possesses its own distinctive properties and advantages, enabling greater versatility and customization in construction projects.

- Q: I have a lot of old aluminum cake pans, coffee pots, pots and pans and various old nuts and bolts made of aluminum. Would it be worth it to scrap them? They really aren't usable for cooking anymore. They are clean.

- Aluminum is currently scrap priced at eighty cents per pound. If you have enough to justify the gasoline to go to a scrap yard, yes it is worth it. Your scrap will end up in Japan rather than in a landfill.

- Q: What are the different methods of surface printing aluminum sheets?

- Some of the different methods of surface printing aluminum sheets include screen printing, offset printing, digital printing, and engraving.

- Q: How to clean the engine oil and kerosene on the surface of aluminum sheet?

- it will disappear after rubbing with petrol.

- Q: This question asks for a list of various types of fasteners that can be used to secure aluminum windows to their frames.

- <p>There are several types of fasteners used for attaching aluminum windows to frames, including: 1. Screws: Commonly used for their secure hold and ease of installation. 2. Nails: Quick to use but may not provide the same level of security as screws. 3. Adhesives: Can be used for a more permanent bond, especially in certain applications. 4. Clips and brackets: Used for a more visible, decorative attachment. 5. Rivets: Provide a strong, permanent connection but are not easily removable. 6. Dowels and pins: Used for a more traditional or decorative join. 7. Structural glazing systems: Employ silicone or other sealants to bond the window to the frame. Each type of fastener has its own advantages and is chosen based on the specific requirements of the project, such as load-bearing needs, aesthetic considerations, and the desired level of permanence.</p>

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

Send your message to us

Aluminum Sheets Colorado Springs for Color Coated Window Glass Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords