Colored Aluminum Foil Sheets for Aluminium Window and Door Profile/Extrusions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Window and Door Profile/Extrusions Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Window and Door Profile/Extrusions:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

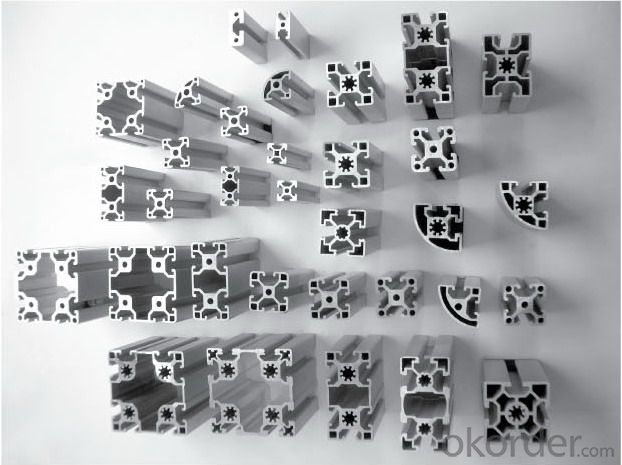

3.Aluminium Window and Door Profile/Extrusions Images:

4.Aluminium Window and Door Profile/ExtrusionsSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

① How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum sheets suitable for chemical reactors?

- Yes, aluminum sheets are suitable for chemical reactors as they possess excellent corrosion resistance, high thermal conductivity, and are lightweight, making them ideal for various chemical reactions.

- Q: What is the typical price range for aluminum sheets?

- The typical price range for aluminum sheets can vary depending on factors such as size, thickness, and quality. However, generally speaking, aluminum sheets can range anywhere from $0.25 to $3 per square foot.

- Q: What are the different methods for joining aluminum sheets?

- There are several methods for joining aluminum sheets, depending on the specific application and desired outcome. Some of the common methods include: 1. Welding: Aluminum can be welded using various techniques such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW). TIG welding is commonly used for thin aluminum sheets, providing a strong and precise joint. MIG welding is suitable for thicker sheets and offers faster production rates. RSW involves passing an electric current through the sheets, melting the aluminum at the contact points, and then applying pressure to create a solid joint. 2. Mechanical Fasteners: Bolts, nuts, and screws can be used to join aluminum sheets together. They provide a strong and reliable connection that can be easily disassembled if needed. Rivets are another common mechanical fastening method, where a rivet gun is used to secure the sheets by deforming the rivet. 3. Adhesive Bonding: Specialized adhesives designed for aluminum bonding can be used to join sheets together. This method is often used when aesthetics are important, as it provides a clean and seamless appearance. Adhesive bonding also distributes the stress evenly across the joint, reducing the risk of localized stress concentration. 4. Clinching: Clinching is a cold joining process where a punch is used to deform the aluminum sheets, creating a mechanical interlock. This method is quick, cost-effective, and does not require additional materials like fasteners or adhesives. 5. Friction Stir Welding (FSW): FSW is a solid-state joining process that uses a rotating tool to generate friction between the aluminum sheets. The friction heats the material, making it pliable, and the rotating tool then stirs the softened material together to form a solid joint. FSW is particularly suitable for joining thicker aluminum sheets. Each joining method has its own advantages and disadvantages, and the choice depends on factors such as the desired strength, appearance, production rate, and the specific requirements of the application.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of residential buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in residential buildings. They offer several advantages such as durability, resistance to weather and corrosion, and low maintenance. Aluminum is lightweight, which can reduce structural load, and it can be easily shaped and installed. Additionally, it has good thermal performance and can be combined with insulation for energy efficiency. However, it's important to consider the aesthetic appeal, as aluminum may not match the traditional look of some residential buildings, and ensure it meets local building codes and standards.</p>

- Q: What kind of aluminum sheet can be bent with five millimeters?

- The aluminum plate can be bent five milimeter too much, if only bending words and aluminum quality has little relationship.First of all, the state is the most important, the state is divided into hard, semi hard, soft (usually soft called O state)The bending effect of the whole hard is not too far (the aluminum plate is H18, H19, H38 and so on are all hard)Semi hard aluminum sheets can basically be bent (H24, that is, semi hard)O bending is certainly not a problem, but because of too soft, basically with this state to bend lessSecond, you have to choose pure aluminum or alloy aluminum?Pure aluminum hardness is not very good, with 1100, 1050, 1060 and so on can be recommended 1100 H26Alloy aluminum hardness is better, can use 3003, 3005, 5052 and other semi hard state can be.Specific recommendations were then determined by 6061, 2024, 7075 if the hardness is too high, especially for the T6 state is more, should not bend, unless you're heating and folding the difference between aluminum and aluminum is poor oxidation resistance, tolerance, surface effect, crystal accuracy and the uniform stability of a difference, not only the bending effect difference.If the aluminum surface paint it quality do not too good, good is a waste, it is recommended to use 3003-H26, 3005H24 or 5052H34, the price of twenty pieces of it, made up to more than forty yuan per kilogram

- Q: I am ultimately looking to have a bike that is good for both everday commuting and touring with panniers/racks long distance with camping. From what I've read on the internet steel frames are more forgiving and ride smoother. The guy at my local bike shop tells me aluminum frames have more flex and ride better. I don't know if he's just trying to make a sale (Giant dealer) or to trust him, unfortunately the staff there are all just racers not tourers. If you can recommend any brands/models to check out that'd be good. From my research thus far I am in love with Co Motion bikes, just not the price! I'm looking at $1000 max for a good touring bike. Thanks!

- Surly LHT Surly Cross Check - suitable for lighter touring Soma Saga Salsa Fargo - heavy duty rig Salsa Casseroll - for light touring Kona Sutra - another mtb-based tourer Bob Jackson World Tour Nothing is as cheap as the nashbar alum frame. No reason to completely rule out aluminum options, though. Steel offers a nice ride, but frames made with nicer steel tubes are probably out of your price range. Aluminim can be plenty strong, especially if it's a hybrid-type frame. For example, Trek's 7.3 would be a fine platform for building a touring bike, yet the frame is aluminum...but plenty strong...and the quality of the frame will exceed an LHT. If you've got to have steel and don't have much funds available, even for a $450 frameset, consider sourcing an older (late-80s to mid-90s) rigid mtb. These had longer chainstays and wheelbases than modern mountain bikes, and the tubing and construction was naturally durable. Yeah, I see your point #2, but if wishes were horses...

- Q: Are there any formulators out there that have any ideas on putting together a cleaner that removes carbon (baked on grease) from an aluminum pan without attacking the meatal itself?? Ive been thinking about this problem for a while and would appriciate any ideas you guys might have. Thanks

- This is the major topic of research for many commercial companies which prepare Oven and Grill cleaning products. The carbon itself is bound to the metal with denatured (carbonized) fat or oil molecules. These are generally effected only by very strong bases such as Sodium hydroxide (lye) which will react with aluminum and cause discoloration and chemical pitting. Mechanical removal using sharp blades or soft metal bristle brushes will work, but requires much labor. Steel wool is also used, but removes some of the metal from the surface of the pans. Special electrical devices have been used with success, but tend to slowly wear away the top layer of aluminum. Professional cooks ignore the problem by replacing aluminum with stainless steel pans. Home and do-it your-selfers tend to allow the buildup until everything sticks and then replace the pans. There has been a few who have seasoned their aluminum pans in a fashion similar to cast iron with mixed results. If this is for pizza pans for your restaurant, I suggest soaking the pans overnight in a strong solution of Dawn Dish-washing Liquid and then taking the pans to a steam car wash to remove the detergent.

- Q: What are the different alloys used in aluminum sheets?

- Aluminum sheets utilize a variety of alloys, each possessing its own distinct properties and characteristics. Some commonly employed alloys include: 1. Alloy 1100: Renowned for its exceptional corrosion resistance and superior electrical conductivity, this alloy finds extensive utilization in applications necessitating high formability and weldability. Examples include food packaging and electrical conductors. 2. Alloy 3003: Esteemed for its formidable formability, moderate strength, and outstanding corrosion resistance, this alloy enjoys widespread application in cooking utensils, chemical equipment, and general sheet metal work. 3. Alloy 5052: Recognized for its robust strength and commendable corrosion resistance, this alloy frequently finds application in marine settings, as well as aircraft fuel tanks and automotive components. 4. Alloy 6061: One of the most versatile and frequently employed aluminum alloys, this variant boasts excellent corrosion resistance, satisfactory weldability, and moderate strength. It is commonly utilized in structural components like frames and railings, as well as automotive and aerospace applications. 5. Alloy 7075: Distinguished by its impressive strength-to-weight ratio and exceptional fatigue resistance, this alloy is often chosen for applications necessitating formidable strength, such as aircraft and aerospace components, as well as high-performance sporting goods. These examples merely scratch the surface of the numerous alloys employed in aluminum sheets. The selection of a particular alloy hinges on the specific requirements of the application, encompassing factors such as strength, corrosion resistance, formability, and weldability.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Aluminum sheets are indeed suitable for food preparation surfaces. They are a lightweight and durable option extensively utilized in the food industry. Being non-toxic and non-reactive, aluminum does not pose any risk of releasing harmful chemicals upon contact with food. Moreover, aluminum sheets are highly convenient to clean and maintain, making them a preferred choice for both commercial and home kitchens. Furthermore, aluminum boasts excellent heat conductivity, ensuring even cooking and baking. Nevertheless, it is worth mentioning that aluminum may react with acidic or salty foods, resulting in a metallic taste. To prevent this, it is advisable to place a layer of parchment paper or a silicone baking mat as a barrier between the aluminum sheet and the food.

- Q: What are the cost considerations when purchasing aluminum sheets?

- There are several cost considerations when purchasing aluminum sheets. Firstly, the size and thickness of the sheets will affect the price, with larger and thicker sheets generally being more expensive. Additionally, the grade and quality of the aluminum will impact the cost, as higher-grade alloys tend to be pricier. The quantity of sheets being purchased also plays a role, as bulk orders often come with discounts. Finally, transportation and delivery costs should be taken into account, especially if the supplier is located far from the buyer.

Send your message to us

Colored Aluminum Foil Sheets for Aluminium Window and Door Profile/Extrusions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords