Brushed Aluminum Sheets Laminate Aluminium Profile Windows and Doors Extrusion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile Windows and Doors Extrusion Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of theAluminium Profile Windows and Doors Extrusion:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

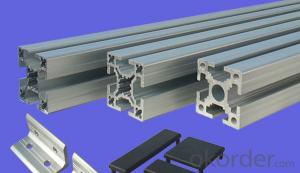

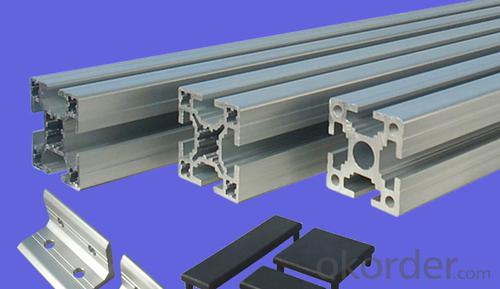

3.Aluminium Profile Windows and Doors Extrusion Images:

4.Aluminium Profile Windows and Doors Specification Extrusion:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I am trying to find away of turning aluminum oxide or alumina into just aluminum. Please post all ideas i dont care how crazy.

- ensure u have distilled water cuz if there is salt in it, u might finally end up freeing chlorine interior the air and die. haha. ok, take a 9 -12 volt battery or something like that and placed 2 wires from the positve and unfavourable ends interior the water. the only cord that bubbles extra is the hydrogen. so turn a attempt tube and placed it interior the water and so as that there is not any air interior the attempt tube. whilst the cord is going in, the hydrogen will fill it up and u'll be left with organic hydrogen interior the tube. i don't be conscious of if i defined it perfect yet there are a team of video clips on youtube. examine them out.

- Q: What are the different surface finishes available for aluminum sheet?

- There are several surface finishes available for aluminum sheet, including mill finish, brushed finish, anodized finish, and painted finish.

- Q: Is it possible to utilize recycled aluminum scraps as an alternative to purchasing new aluminum sheets for a project?

- <p>Yes, you can use recycled aluminum scraps in your project instead of buying new aluminum sheets. Recycled aluminum is not only environmentally friendly but also cost-effective. It has similar properties to new aluminum, making it suitable for many applications. However, ensure the quality and purity of the recycled aluminum meet your project's requirements. Check for any impurities or inconsistencies that might affect the strength or performance of your final product. If the recycled aluminum is in good condition and appropriate for your needs, it can be a sustainable and economical choice.</p>

- Q: Can aluminum sheets be laminated?

- Yes, aluminum sheets can be laminated. Lamination involves bonding a layer of material, such as plastic or paper, to the surface of the aluminum sheet to provide protection, enhance aesthetics, or improve functionality.

- Q: This question asks for a list of various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheet coatings are applied to enhance properties such as corrosion resistance, appearance, and durability. Common types include: 1. Anodized coatings, which provide a hard, wear-resistant surface. 2. Painted coatings, which can be solvent-based or water-based and offer a range of colors. 3. Powder coatings, which are electrostatically applied and then cured for a durable finish. 4. Laminate coatings, which are plastic films bonded to the aluminum for added protection and aesthetics. 5. Clear coatings, which are transparent and protect the aluminum without altering its appearance. 6. PVD (Physical Vapor Deposition) coatings, which provide a thin, hard layer for enhanced scratch and corrosion resistance. Each type serves different purposes and has unique properties that make it suitable for specific applications.</p>

- Q: I constructed a small hho generator for experimental purposes. I needed to add a cooling condenser to the unit because of a overheating problem. I was using a old heater core from a vehicle, soldered some joints to make some connections. the solution seemed to have eaten the solder I used, which was normal lead free solder used in water pipes. I was going to invest into a trans cooler core which is made of aluminum, but I need to know if the solution will eat up the aluminum. I also thought about using a condenser core from a broken window a/c, which is made of copper tubing. any advise would be very help full

- Aluminum, yes; copper, no. Aluminum is attacked by both acids and bases (it is what is called amphoteric); copper is attacked by neither -- although nitric acid will attack copper by oxidizing it. Solder joints may be attacked by acid, but may be more or less immune to attack by strong bases, depending on what is in the solder.

- Q: What are the different methods for punching aluminum sheets?

- There exist numerous techniques for punching aluminum sheets, each possessing its own advantages and applications. Among the different methods are: 1. Manual Punching: This approach entails using handheld tools like handheld punches or hole punches to manually create holes or shapes in the aluminum sheet. It is appropriate for small-scale or low-volume production and provides flexibility in terms of hole size and shape. 2. Mechanical Punching: Mechanical punching involves the utilization of a mechanical press machine equipped with a punch and die set. The sheet is inserted into the machine, and the punch is driven through the material, forming holes or shapes. This technique is quicker and more efficient than manual punching and is fit for medium to high-volume production. 3. CNC Punching: Computer Numerical Control (CNC) punching involves the utilization of automated machinery programmed to punch holes or shapes based on a digital design. The aluminum sheet is loaded onto the machine, and the CNC controls the movement of the punch and die to create precise and intricate patterns. CNC punching offers high accuracy, repeatability, and speed, making it ideal for high-volume production and intricate designs. 4. Laser Punching: Laser punching combines the use of a laser cutter and a mechanical punch to produce holes or shapes in aluminum sheets. The laser beam vaporizes or melts the material, while the punch ejects the cut part from the sheet. This method offers high precision, versatility, and the ability to swiftly cut complex shapes. However, it is typically more expensive and time-consuming compared to other methods. 5. Notching: Notching is a technique employed to create V-shaped or U-shaped cuts in aluminum sheets. It is often used for joining or folding the material to form corners or edges. Notching can be done manually or with the assistance of a mechanical notching machine. The selection of a punching method relies on various factors such as the desired hole size and shape, production volume, precision requirements, complexity of design, and budget. It is crucial to consider these factors and consult with experts to determine the most suitable method for punching aluminum sheets based on specific needs and applications.

- Q: Im wondering what type of clutch would be better for my fox body mustang. A aluminum or steal. And why

- aluminum if you are drag racing ( have to learn to feather the clutch a bit) STEEL on the street( easier to keep the fire lit for mere mortals ) course you can use aluminum on the street--most people cant, because you have to be easy with the clutch-but it gives you an excuse why people cant borrow your car

- Q: What is the maximum temperature that the aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can typically withstand is around 600 degrees Fahrenheit (315 degrees Celsius).

- Q: How much do aluminum sheets typically weigh?

- The weight of aluminum sheets ranges from 1.9 to 3.4 grams per square centimeter, and this varies depending on the sheet's thickness and size. Aluminum sheet weight can differ considerably based on its dimensions and gauge. Thinner sheets are typically lighter, while thicker ones tend to be heavier. It is worth mentioning that factors like the alloy utilized and any surface coatings or treatments can also impact the weight of aluminum sheets. Hence, it is recommended to refer to the product specifications or contact the manufacturer for precise weight details.

Send your message to us

Brushed Aluminum Sheets Laminate Aluminium Profile Windows and Doors Extrusion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords