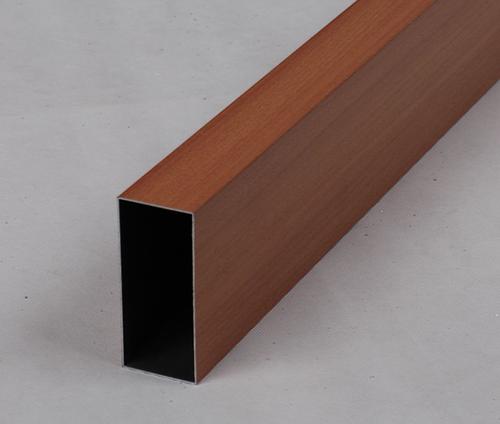

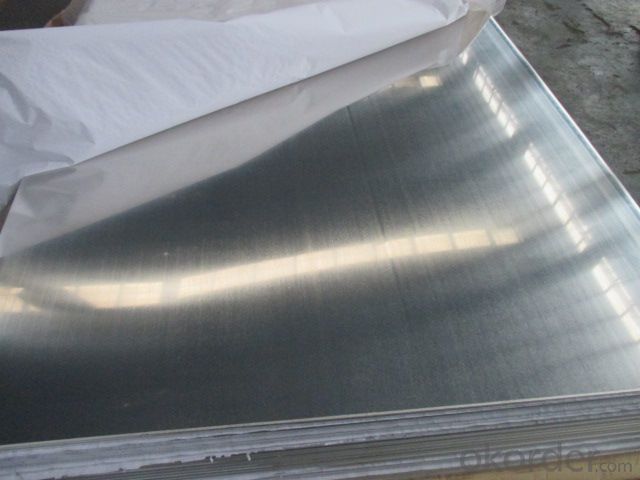

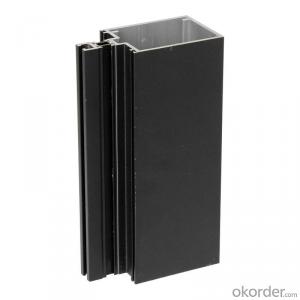

China Made Extruded Aluminum Profiles - Color Coated Aluminum Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1250mm*2500mm/1260mm/1270mm,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What are the durability characteristics of aluminum profiles?

- Aluminum profiles are renowned for their exceptional durability. Their resilience stems from the inherent properties of aluminum, which include its ability to resist corrosion, its lightweight composition, and its impressive strength-to-weight ratio. As a result, aluminum profiles possess remarkable longevity and are built to last. One of the key durability aspects of aluminum profiles lies in their resistance to corrosion. Aluminum naturally develops a thin oxide layer on its surface, which serves as a shield against rust and other forms of corrosion. This quality makes aluminum profiles an excellent choice for outdoor applications that expose them to harsh environmental conditions, such as rain, snow, and UV radiation. Furthermore, aluminum profiles excel at withstanding extreme temperatures without compromising their structural integrity. They possess a high melting point and can endure thermal expansion and contraction, rendering them highly suitable for environments characterized by fluctuating temperatures. Another significant facet of the durability of aluminum profiles is their strength. Despite their lightweight nature, aluminum profiles are incredibly robust and capable of bearing heavy loads and impacts. This remarkable strength-to-weight ratio has contributed to their popularity in diverse industries, including construction, automotive, and aerospace. Moreover, aluminum profiles exhibit exceptional resistance to wear and tear. They boast excellent abrasion resistance and can maintain their structural integrity even after prolonged periods of use. This quality makes them well-suited for applications that require long-term durability, such as window frames, door frames, and structural components. In conclusion, aluminum profiles possess outstanding durability attributes due to their corrosion resistance, lightweight composition, impressive strength-to-weight ratio, thermal stability, and resistance to wear and tear. These characteristics make them a reliable choice for a wide range of applications, ensuring their longevity and performance over an extended period.

- Q: Is it possible to recycle and reuse aluminum profiles?

- <p>Yes, aluminum profiles can be recycled and reused. Recycling aluminum is an efficient and environmentally friendly process, as it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for various applications. The recycling process involves melting the aluminum, which can then be reformed into new profiles without losing its strength or quality. This practice reduces waste and conserves natural resources, contributing to sustainability efforts.</p>

- Q: Calculation of heat dissipation of aluminium profile radiator

- This requires software that is not easy to compute directly, and the formulas may pull out a long string and are inaccurateBecause the contact of the bottom of the profile is initiated by the heat source, the contact area is first set, which affects the distance and conduction angle of the thermal conductivityWhen you change this condition, the whole formula varies greatlyAgain, set convection and convection intensities, convection fluid properties and relative heat exchange efficienciesIn the radiator industry, there have been similar formulas, but only the natural convection settings, and in the heat under the state, heat dissipation at room temperature settingsProfessional software has many, FLOWTHEM, e-therm, ice-pake and so on, even Pro-E seems to be able to hang modules to do simulationSuggest going directly to software

- Q: What are the different tolerance levels for aluminum profiles?

- The specific requirements and applications can cause the tolerance levels for aluminum profiles to differ. Various industries, including automotive, aerospace, and construction, typically demand aluminum profiles with tight tolerance levels. Aluminum profiles commonly have dimensional tolerances, straightness tolerances, and surface finish tolerances. The dimensional tolerances ensure that the profile meets the required measurements and fits properly in its intended application. Typically, these tolerances are specified in millimeters or inches. Straightness tolerances guarantee that the aluminum profile does not deviate from a perfectly straight line. This is vital for maintaining structural integrity and accurate assembly. Surface finish tolerances determine the acceptable level of imperfections on the profile's surface, such as scratches, indentations, or roughness. These tolerances are often specified in terms of roughness average (Ra) or surface quality codes, like anodized or powder-coated finishes. It is crucial to consider that the tolerance levels for aluminum profiles can vary depending on factors such as the manufacturing process, intended application, and industry standards. Therefore, it is essential to consult relevant specifications, industry standards, or the supplier's guidelines to determine the precise tolerance levels for a specific aluminum profile.

- Q: How do aluminum profiles perform in terms of impact resistance?

- Known for their excellent impact resistance, aluminum profiles are able to withstand significant impact without becoming easily deformed or damaged, thanks to their inherent strength and durability. The ideal strength-to-weight ratio of aluminum makes it particularly suitable for industries such as automotive, aerospace, and construction, where impact resistance is crucial. In addition, the structure of aluminum profiles allows them to absorb and distribute impact energy, thereby preventing localized damage. This property proves especially advantageous in situations that require resistance to sudden shocks, collisions, or heavy loads. Moreover, aluminum profiles can be customized with specific reinforcements or structural elements to further enhance their impact resistance. This flexibility allows for meeting specific requirements or addressing areas prone to impact. In summary, the exceptional impact resistance of aluminum profiles makes them highly valued in industries and applications where strength and durability are essential.

- Q: Are aluminum profiles suitable for use in roofing or wall systems?

- <p>Yes, aluminum profiles are commonly used for both roofing and wall systems due to their durability, corrosion resistance, and lightweight properties. They offer a modern aesthetic and can be easily integrated into various architectural designs. Aluminum profiles are also known for their strength and flexibility, allowing for the creation of complex shapes and structures. Additionally, they require minimal maintenance and can withstand harsh weather conditions, making them a popular choice for construction projects.</p>

- Q: This question asks whether aluminum profiles can be utilized for creating interior partitions and seeks reasons for their suitability.

- <p>Yes, aluminum profiles can be used for interior partitions. They are favored for several reasons: they are lightweight yet strong, offering durability and stability. Aluminum profiles are also resistant to corrosion, which makes them suitable for various environments. Their ease of installation and low maintenance requirements make them cost-effective. Additionally, they can be easily customized to fit various design needs, and their recyclability makes them an environmentally friendly choice.</p>

- Q: What is the limitation of aluminum bending

- General extrusion of aluminum quality is soft, over a period of time will be hardened, the longer the material more hard, no impact on the stretch bending, with hydraulic bending machine, there will be no cracks. Dongguan Sheng Hui Machinery Co., Ltd. to serve you. Thanks for taking it

- Q: What does aluminum T1.5 mean?

- Aluminum should be referred to the thickness of 1.5MM thick.

- Q: This question asks about the various methods used to finish aluminum profiles, including painting and coating.

- <p>Aluminum profiles can be finished in several ways to enhance their appearance, durability, and functionality. Common methods include: 1. Anodizing, which provides a protective oxide layer and can be colored. 2. Powder coating, an electrostatic process that offers a durable and colorful finish. 3. Painting, which can be done with various types of paint for aesthetic or protective purposes. 4. Polishing, which gives a shiny, smooth surface finish. 5. Brushing, creating a textured, satin-like appearance. 6. Electroplating, which deposits a thin layer of metal onto the aluminum for decorative or protective reasons. Each method has its advantages and is chosen based on the specific requirements of the application.</p>

Send your message to us

China Made Extruded Aluminum Profiles - Color Coated Aluminum Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords