Adhesive Back Aluminum Oxide Sheets - AA3105 Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA3105 Used for Constrcution Description

Aluminum Sheets AA3105 Used for Constrcutionare widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

Direct Continuous Aluminium Foil Stock in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of Aluminum Sheets AA3105 Used for Constrcution

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

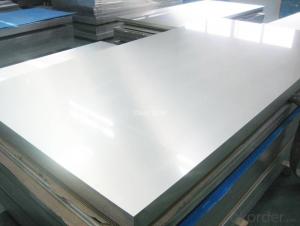

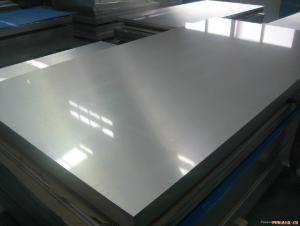

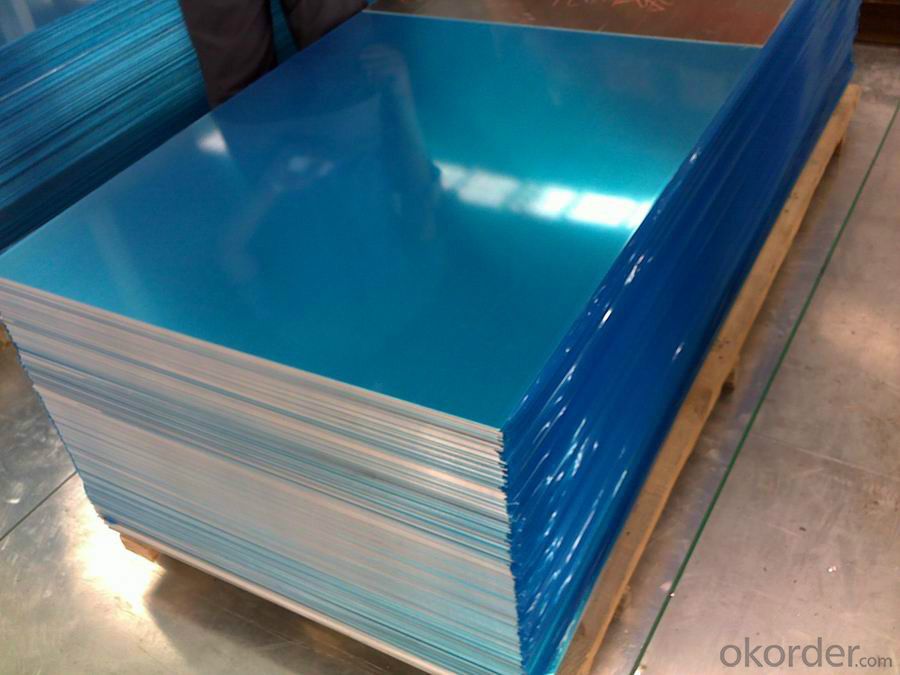

3.Aluminum Sheets AA3105 Used for Constrcution Images

4.Aluminum Sheets AA3105 Used for Constrcution Specification

Alloy | AA3105 |

Temper | H14, H16, H18, H22 |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN |

5. FAQ of Aluminum Sheets AA3105 Used for Constrcution

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA3105 Used for Constrcution.

B.

What is the quality standard?

---Usually our standard is GB3880-2006

C. What is the largest width?

---It is 2300mm

- Q: Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- There are several ways to take care of your problem. 1) Change all the wiring to copper. 2) Pigtail with copper wire and al/cu wirenuts to all new devices 3) Use copalum at all your boxes (this method is the best, besides replacing all your wiring to copper). Basically it cold welds the aluminum to the copper and makes a molecular bond. It's pretty expensive, and you'll have to look to find someone that actually knows how to do it, and has access to the crimping tool. Going around and tightening your devices won't hurt, but won't be fixing any longer term issues you may have with the aluminum wire. Keep in mind that if the original installation was done correctly, your circuits aren't overly tapped, and all the wires are on the appropriately sized breakers, then you may not have to worry much. Just run dedicated lines to any your new circuits. In other words, don't tap off these circuits. Hope this helps.

- Q: Can aluminum sheets be used as heat shields?

- Yes, aluminum sheets can be used as heat shields. Aluminum has excellent thermal conductivity, meaning it can efficiently conduct and transfer heat away from the source. Additionally, aluminum has a high melting point, allowing it to withstand high temperatures without warping or deforming. These properties make aluminum sheets an ideal choice for heat shield applications, such as protecting sensitive components or structures from heat damage in various industries including automotive, aerospace, and industrial applications. Furthermore, aluminum is lightweight and relatively easy to shape, making it a practical choice for heat shields that need to be installed in tight spaces or require complex designs. Overall, the use of aluminum sheets as heat shields offers effective thermal protection while providing durability, versatility, and cost-effectiveness.

- Q: What unique considerations or prerequisites are necessary when installing aluminum sheets?

- <p>When installing aluminum sheets, there are several special requirements to consider. First, ensure that the surface is clean, dry, and free of any debris to guarantee proper adhesion. Use appropriate fasteners designed for aluminum to prevent corrosion. Measure and cut the sheets accurately to fit the intended area, as aluminum can be prone to warping if not handled correctly. Additionally, consider the environmental conditions, such as temperature and humidity, which can affect the installation process. Always follow the manufacturer's guidelines for installation and safety precautions.</p>

- Q: Can aluminum sheets be used for electrical busbars?

- Yes, aluminum sheets can be used for electrical busbars. Aluminum is a commonly used material for busbars due to its excellent electrical conductivity, lightweight nature, and cost-effectiveness. However, it is important to consider factors such as current carrying capacity, temperature rise, and mechanical strength when selecting aluminum sheets for busbar applications.

- Q: hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- OK. the first thing is that you can connect copper to aluminum. They make wire that is called copper clad aluminum and is exactly what it sounds like, but you don't have to install that. So if you want to install a junction box just make sure that it remains exposed and that you secure the wire within 12 inches of the box. About your light. I would simply put up another fixture, just make a visual inspection of the wire. if it is all roughly the same shade then it is most likely still fine. The only damage that is done by replacing a fixture to much is to the wire that is inside of the box and if something happens to that it will not start a fire, the light simply won't work.

- Q: What is the bending radius of aluminum sheets?

- The bending radius of aluminum sheets is influenced by several factors, including the sheet thickness, the type of aluminum alloy used, and the bending method employed. In general, aluminum sheets with a thickness of 1mm or less can be bent without cracking if the radius is equal to the thickness of the sheet. For thicker aluminum sheets, it is necessary to have a bending radius that exceeds the thickness of the sheet in order to prevent cracking or fracturing. As a rule of thumb, aluminum sheets with a thickness ranging from 1mm to 6mm should have a bending radius at least 1.5 times the sheet thickness. For instance, a 3mm thick aluminum sheet should have a minimum bending radius of 4.5mm. It is important to note that these guidelines are approximate and can vary depending on the specific aluminum alloy and temper utilized. Additionally, different bending processes, such as air bending, bottoming, or coining, may require different bending radii. To obtain precise bending radius requirements for specific applications of aluminum sheets, it is advisable to consult the manufacturer's specifications or seek professional advice.

- Q: This question asks about the structural integrity and suitability of aluminum sheets for use in the construction of high-rise buildings.

- <p>Aluminum sheets are not typically used as the primary structural material in high-rise buildings due to their lower strength compared to steel and concrete. However, aluminum is known for its high strength-to-weight ratio, making it suitable for non-structural applications such as facades, window frames, and roofing. In high-rise construction, aluminum can be used in combination with other materials to provide a lightweight and aesthetically pleasing exterior while maintaining structural integrity with stronger materials like steel and concrete.</p>

- Q: i know the 4100 is aluminum........im wondering if this one is also..

- Yes, the whole thing is aluminum

- Q: Can aluminum sheets be plasma cut?

- Yes, aluminum sheets can be plasma cut. Plasma cutting is an effective method for cutting aluminum sheets as it utilizes a high-temperature plasma arc to melt and remove the metal, resulting in clean and precise cuts.

- Q: Are 101 aluminum sheets suitable for mold making?

- No, 101 aluminum sheets are generally not suitable for mold making. While aluminum is a commonly used material for making molds due to its durability and heat resistance, 101 aluminum is a low-strength alloy that may not meet the requirements for mold making. For such purposes, it is recommended to use aluminum alloys with higher strength and hardness, such as 6061 or 7075 alloys. These alloys offer better resistance to wear, deformation, and heat, making them more suitable for creating molds that can withstand the pressures and temperatures involved in the molding process.

Send your message to us

Adhesive Back Aluminum Oxide Sheets - AA3105 Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords