Powder Coated Aluminum Profiles for Door and Window Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

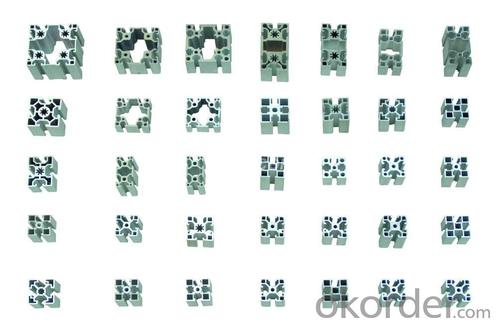

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: What are the standard dimensions of aluminum profiles?

- The standard dimensions of aluminum profiles can vary depending on the specific industry and application. However, there are some common standard dimensions that are widely available. In general, aluminum profiles come in a variety of shapes and sizes, including rectangular, square, circular, and custom shapes. The most common dimensions for rectangular aluminum profiles are typically between 1 inch to 6 inches in width and 1/2 inch to 4 inches in height. Square profiles often range from 1 inch to 4 inches in width and height. Circular aluminum profiles, also known as tubes or pipes, are typically available in various outer diameters ranging from 1/4 inch to 8 inches, with wall thicknesses ranging from 1/16 inch to 1/2 inch. It's important to note that these are general standard dimensions and there can be variations depending on the manufacturer and specific requirements of a project. Additionally, custom dimensions can be manufactured to meet unique specifications. When selecting aluminum profiles, it's crucial to consider the intended application and load-bearing requirements to ensure the chosen dimensions can adequately support the intended use.

- Q: Can aluminum profiles be used in curtain wall systems?

- Yes, aluminum profiles can be commonly used in curtain wall systems. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for constructing curtain walls. Its versatility allows for various design options and structural support, making it a popular choice in the construction industry.

- Q: Can aluminum profiles be used for electrical busbars?

- Yes, aluminum profiles can be used for electrical busbars. Aluminum offers excellent electrical conductivity, and its lightweight nature makes it a cost-effective choice for busbar applications. Additionally, aluminum profiles can be easily shaped and customized to meet specific requirements, making them suitable for various electrical systems.

- Q: This question asks for methods to ensure that the installation of aluminum profiles is both cost-effective and efficient.

- <p>To ensure the installation of aluminum profiles is cost-effective and efficient, follow these steps: 1) Plan carefully: Use accurate measurements and detailed plans to minimize waste and rework. 2) Use quality materials: Invest in high-quality aluminum profiles to reduce maintenance and replacement costs. 3) Employ skilled labor: Well-trained installers can complete the job faster and with fewer errors. 4) Optimize the installation process: Streamline the process to reduce time and labor costs. 5) Regular maintenance: Proper care and maintenance can extend the life of aluminum profiles, saving on replacement costs. 6) Compare suppliers: Shop around for the best prices and quality to minimize costs. 7) Use modular designs: Modular systems can be more efficient to install and easier to modify in the future.</p>

- Q: How is the price of aluminum profile calculated?

- General Factory aluminum prices are in accordance with the composition of component models of aluminum ingot price plus processing fees in the form of the aluminum price is reference price (the South China Sea coastal area informed factory according to the settlement price) or the Yangtze River (the mainland manufacturers in accordance with the price of aluminum ingots, aluminum price settlement price) every day is not the same, can check on the Internet to the price of aluminum ingots (holidays are closed, no aluminum price), and processing fees for each plant according to surface treatment you need and pricing, general spraying at around 4500, around 5500 (compared with ordinary electrophoresis but also can plant, GB material processing fee).

- Q: How do aluminum profiles perform in terms of vibration resistance?

- The excellent vibration resistance properties of aluminum profiles are well-known. This is because aluminum has inherent characteristics, such as being lightweight and having a high strength-to-weight ratio, which enable it to effectively dampen vibrations. By absorbing and dissipating energy generated by vibrations, aluminum profiles reduce the risk of structural damage and ensure the integrity of the entire system. Moreover, aluminum profiles can be designed with different geometries and cross-sectional shapes, enhancing their stiffness and rigidity. This improved structural stability minimizes the transmission of vibrations throughout the profile, resulting in reduced resonance and vibration amplification. Additionally, aluminum profiles can be further enhanced through various methods, including extrusion processes and surface treatments. The use of extrusion processes allows the aluminum profiles to be shaped into specific configurations, optimizing their vibration resistance capabilities. Surface treatments, such as anodizing or powder coating, provide an additional layer of protection against corrosion and wear, thereby enhancing the longevity and performance of the profiles. In conclusion, aluminum profiles are highly effective in resisting vibrations due to their lightweight nature, high strength-to-weight ratio, and the ability to be customized for specific applications. These qualities make them an ideal choice for a wide range of industries, including automotive, aerospace, and construction, where vibration control is essential for maintaining product performance and safety.

- Q: How do you prevent galvanic corrosion in marine environments with aluminum profiles?

- One way to prevent galvanic corrosion in marine environments with aluminum profiles is by using sacrificial anodes made of a different, more active metal. These anodes, typically made of zinc or magnesium, are connected to the aluminum profiles and act as a sacrificial material that corrodes instead of the aluminum. This helps in protecting the aluminum profiles from galvanic corrosion. Additionally, proper insulation and coating of the aluminum profiles can also be effective in preventing direct contact with other metals and reducing the risk of galvanic corrosion.

- Q: What are the differences between the 6005 and 6003 aluminum profiles?Yangmingxg3

- 6003 of the magnesium content is higher than 6005, and the strengthening of magnesium to aluminum is remarkable. With the addition of 1% mg, the tensile strength increases by about 34MPa.

- Q: What are the different types of fasteners used for aluminum profiles?

- There are several types of fasteners that are commonly used for aluminum profiles: 1. T-slot nuts: T-slot nuts are designed to fit into the T-slot grooves of aluminum profiles. They have a threaded hole that allows for the attachment of bolts, screws, or other fasteners. 2. Bolts and screws: Bolts and screws are used to secure aluminum profiles together or to other components. They come in a variety of lengths and sizes to accommodate different applications. 3. Corner brackets: Corner brackets are used to create strong joints between aluminum profiles at right angles. They typically have holes for screws or bolts, allowing for easy attachment. 4. T-bolts: T-bolts are similar to regular bolts, but they have a T-shaped head that fits into the T-slot grooves of aluminum profiles. This allows for quick and secure attachment without the need for nuts or additional hardware. 5. Angle brackets: Angle brackets are used to create joints between aluminum profiles at different angles. They typically have holes for screws or bolts, making it easy to secure the profiles together. 6. Clamps: Clamps are used to hold aluminum profiles in place or to attach them to other components. They come in various designs, such as lever clamps or eccentric clamps, and can be easily adjusted and tightened for a secure fit. 7. End caps: End caps are used to cover the ends of aluminum profiles, providing a finished look and protecting the profile from debris or damage. These are just a few examples of the different types of fasteners used for aluminum profiles. The choice of fastener will depend on the specific application and the desired level of strength and versatility.

- Q: The side wall of the box body is a heat sink, and the exposed end of the heat radiating fin can not damage the surface, and the inner surface is made of four M3h6 internal thread nut columns, which is welded? Or press riveting? Heat sink is extruded aluminum profile, the thickness of 5.5mm, slotted deep 2.5mm, how should this process? Do you have this nut column?

- Let me seeGenerally speaking, there are more riveting nuts,Threads are also drilled and tapped and threaded with steel threadBut according to the actual situation to decide

Send your message to us

Powder Coated Aluminum Profiles for Door and Window Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords