Heavy Duty Aluminum Foil Sheets - Mill Finished Continuous Casting Aluminium Circle AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

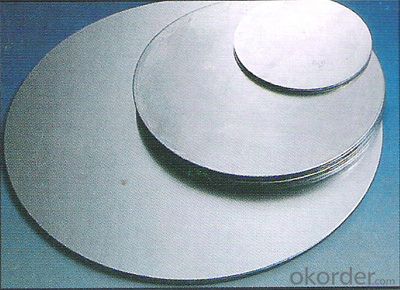

Mill Finished Continuous Casting Aluminium Circle is one semi-finished aluminium material. It can widly used in the kitchens. For example, it can be produced into pan, cup, pot ect. This material can be mainly exported to African market.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image:

4.Products Specification

| Alloy | Thickness | Diameter | Temper | Surface |

| AA1050 | 0.2mm-3mm | 99mm-1200mm | H14,H16,H24 | Mill finished |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum sheets suitable for electrical busbars?

- Electrical busbars can indeed be made from aluminum sheets. Aluminum is extensively used in the electrical industry due to its exceptional electrical conductivity, lightweight properties, and affordability in comparison to metals like copper. Aluminum sheets can be easily shaped and sized to fit the required dimensions for busbars, making them a versatile choice for electrical applications. Moreover, aluminum possesses commendable thermal conductivity, aiding in the dissipation of heat generated during electrical operations. However, it is crucial to acknowledge that aluminum has a lower electrical conductivity than copper, necessitating larger cross-sectional areas to achieve equivalent electrical performance. Consequently, it is vital to consider the specific requirements of the electrical system and seek expert advice to determine the suitability of aluminum sheets for a particular busbar application.

- Q: I have been doing this science prac at school and I have received some strange results. I measured the density of this metal, which leads me to believe it is Aluminium. Also, its silvery appearance supports this. When I have attempted to react it with Hydrochloric Acid, Sulfuric Acid and the nitrates/chlorides of a few metals, I have received some odd results.Despite having a high reactivity, the only substance it has reacted with so far out of all of the above is Tin Chloride. Am I doing something wrong? Is it possible that it isn't aluminium and rather a similar metal such as zinc? Thanks in advance :)

- Aluminum is very reactive so what happens is that it has a coat aluminum oxide as soon as it comes in contact with oxygen the outer layer forms aluminum oxide Al2O3. That is why Aluminum does not rust. The Al203 coat protects it.

- Q: How do you prevent warping of aluminum sheets during machining?

- There are several measures that can be taken to prevent warping of aluminum sheets during machining: 1. Proper material selection is crucial in minimizing warping. Opt for aluminum alloys with lower levels of thermal expansion, like 6061 or 7075, as they are less prone to warping. 2. It is recommended to stabilize the material before machining by annealing or stress-relieving the aluminum sheets. This process reduces internal stresses and decreases the likelihood of warping. 3. Ensure the use of appropriate cutting tools. Opt for tools with sharp edges and proper geometry to minimize heat generation and facilitate efficient chip removal. Carbide or diamond-coated tools are often preferred for their high heat resistance when machining aluminum. 4. Minimize heat generation during machining, as excessive heat can cause warping. Implement the use of coolant or lubricants to reduce friction and dissipate heat. Continuous cooling helps maintain a stable temperature and prevents warping. 5. Properly control cutting parameters such as cutting speed, feed rate, and depth of cut to prevent warping. High cutting speeds or excessive material removal rates generate excessive heat, which leads to warping. Experimentation and experience should determine the optimal parameters. 6. Use appropriate fixturing during machining to minimize the chances of warping. Securely clamp the aluminum sheets using suitable fixtures or jigs to maintain stability and prevent movement. 7. Consider employing machining techniques like climb milling or ramping, which reduce vibrations and ensure a smoother cutting process, thereby reducing the risk of warping. 8. After machining, it is advisable to stress-relieve the aluminum sheets again. This step further reduces any residual stress that may have developed during the machining process. By adhering to these steps, the chances of warping during the machining of aluminum sheets can be significantly reduced, resulting in high-quality finished products.

- Q: This question asks about the influence of aluminum sheets on the thermal insulation properties of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can actually reduce the insulation of a building if not properly used. They can conduct heat quickly, which means that they may transfer heat from the outside to the inside or vice versa, depending on the temperature difference. This can lead to increased energy consumption for heating or cooling. However, when used as a reflective barrier in combination with proper insulation materials, aluminum sheets can help reflect heat and improve insulation by reducing heat transfer. It's crucial to use aluminum sheets correctly and in conjunction with other insulating materials to achieve optimal thermal performance in buildings.</p>

- Q: Are the aluminum sheets suitable for electrical conductivity applications?

- Indeed, aluminum sheets prove to be a fitting option for electrical conductivity applications. Possessing a high level of conductivity, aluminum demonstrates an electrical conductivity that is approximately 61% of copper's. Consequently, it has become widely favored for a multitude of electrical and electronic applications that prioritize conductivity. Notably, aluminum sheets find purpose in the fabrication of power transmission lines, electrical cables, bus bars, and heat sinks, among other uses. Furthermore, aluminum boasts attributes such as lightweightness, resistance to corrosion, and commendable thermal conductivity, all of which contribute to its suitability for electrical conductivity applications.

- Q: What paint is better to paint on the brushed aluminum sheet? Simple process and good adhesion!

- Car paint is better, you can go to the auto paint repair department to buy a little, but pay attention to two points: 1., the oil on the aluminum alloy solvent cleaning. 2. can not spray thick, otherwise it will rise.

- Q: Not just cans. How is aluminum recycled and what is the process. Not the scientific formula! How its done entering the plant.

- First, aluminum is shredded. It is then melted and turned into molten aluminum. Once it becomes molten, the used aluminum does not differ from new aluminum. It is then molded into the new product. Recycling aluminum is much more energy efficient than melting new ore into aluminum because it takes three times the energy to produce than if it was recycled.

- Q: Hi, I'm new here. Yoroshigu.I'm trying to make flash paper for magic tricks.To do that I have to make flash powder but in my location I can hardly find ingredients. Not to think about buying. Usually, I wait for a season and buy firecrackers. Then, I take the power and soak them into the paper and dry. This works but not so flash. Burned more likely.So, I wonder if I take aluminium oxide from aluminium oxide sandpaper and mix with powder from firecracker would produce a brighter flash than firecracker power alone?anyone know please share.

- Aluminum oxide is a ceramic. Ceramics are already, in their lowest energy state and won't give you the effect you're looking for: The sand (that's all aluminum oxide is) that you're adding will make your flash dimmer (and dirtier). You want to get some aluminum metal powder. It is very reactive, and will make your flash appear much brighter. You're on your own as far as the safety of this.

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed. Roll forming is a process in which a continuous strip of metal, in this case, aluminum, is fed through a series of rollers to gradually shape it into a desired profile or shape. Aluminum is an ideal material for roll forming due to its malleability and ductility, allowing it to be easily bent, curved, and formed into various shapes. It is commonly used in industries such as construction, automotive, and aerospace for applications that require lightweight yet durable components.

- Q: Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum is a good choice for insulation jackets as it is lightweight, durable, and has excellent thermal conductivity. It can effectively reflect heat and prevent heat transfer, making it an efficient material for insulation purposes.

Send your message to us

Heavy Duty Aluminum Foil Sheets - Mill Finished Continuous Casting Aluminium Circle AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords