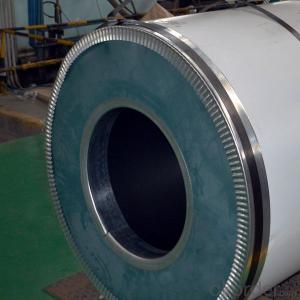

Cold Rolled Stainless Steel sheets NO.2B Finish Grade 316L 4mm thickness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

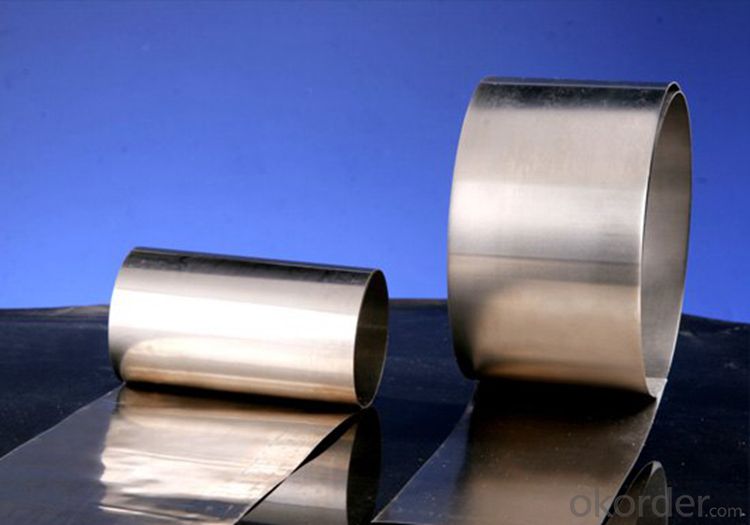

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What is the difference between brushed and polished stainless steel sheets?

- Brushed and polished stainless steel sheets differ in terms of their appearance and texture. Brushed stainless steel sheets have a textured, matte finish that is achieved by brushing the stainless steel surface with an abrasive material. This creates a series of parallel lines or a pattern on the metal, giving it a distinctive look. The brushed finish helps to hide scratches and fingerprints, making it a popular choice for applications where durability is important. On the other hand, polished stainless steel sheets have a smooth, glossy finish that is achieved by polishing the surface with a fine abrasive compound. This process removes any imperfections or scratches on the metal, resulting in a mirror-like reflection. The polished finish is more reflective and visually appealing, making it commonly used in decorative applications where aesthetics are a priority. In summary, the main difference between brushed and polished stainless steel sheets lies in their appearance and texture. While brushed stainless steel sheets have a textured, matte finish that is more resistant to scratches and fingerprints, polished stainless steel sheets have a smooth, glossy finish that provides a mirror-like reflection. The choice between brushed and polished stainless steel sheets depends on the desired aesthetic and the specific application requirements.

- Q: Are stainless steel sheets suitable for food processing?

- Yes, stainless steel sheets are highly suitable for food processing. Stainless steel is a strong and durable material that is resistant to corrosion, heat, and chemical damage. It is non-reactive with food, which ensures that it will not affect the taste or quality of the processed food. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for food processing environments.

- Q: Are stainless steel sheets suitable for roofing applications?

- Yes, stainless steel sheets are suitable for roofing applications. Stainless steel is known for its durability, resistance to corrosion, and strength, making it an ideal material for roofs. It can withstand harsh weather conditions, including extreme temperatures, high winds, and heavy rainfall. Stainless steel sheets are also fire-resistant, which adds an extra layer of safety to the roof. Additionally, stainless steel has a long lifespan, requiring minimal maintenance and repairs. Overall, stainless steel sheets provide a reliable and long-lasting solution for roofing applications.

- Q: What are the common applications for stainless steel sheets?

- Stainless steel sheets are commonly used in a variety of applications due to their durability, corrosion resistance, and aesthetic appeal. Some common applications include kitchen appliances, automotive parts, construction materials, medical equipment, and industrial machinery.

- Q: How do you prevent distortion when welding stainless steel sheets?

- In order to prevent distortion while welding stainless steel sheets, it is important to follow several key steps and precautions: 1. Begin by ensuring that the stainless steel sheets are thoroughly cleaned and free from any contaminants, such as oil, grease, or dirt. Use an appropriate solvent or degreaser to clean the surfaces before welding. This will help to avoid trapping impurities in the weld, which can cause distortion. 2. Accurate fit-up of the stainless steel sheets is crucial to minimize distortion. Make sure that the edges of the sheets are properly aligned and that there are no gaps or misalignments. Proper clamping or tacking can also help to maintain the correct position of the sheets during welding. 3. Controlling the heat input is essential to prevent excessive distortion. Use the appropriate welding technique, such as TIG or MIG, to control the heat. Avoid overheating the stainless steel sheets, as this can lead to warping and distortion. It is important to maintain a consistent and controlled heat input throughout the welding process. 4. Plan the weld sequence properly to minimize distortion. Start from the center and work outward in a balanced manner to distribute the heat evenly. This will prevent localized heating, which can cause distortion. Alternating between sides and allowing each weld to cool before moving to the next one can also help reduce distortion. 5. Choose the right welding technique and parameters. For example, using a lower heat input, slower travel speed, and smaller weld bead can minimize distortion. Additionally, using a backstep technique, where the weld travels in a forward and backward motion, can help distribute the heat and reduce distortion. 6. Consider preheating the stainless steel sheets to reduce the temperature gradient and minimize distortion. Ensure that the preheating temperature is within the recommended range for the specific stainless steel grade. After welding, it is advisable to perform post-weld treatment, such as stress relieving, to minimize residual stresses that can lead to distortion. By following these steps and precautions, it is possible to significantly reduce distortion when welding stainless steel sheets. However, it is important to note that each welding process and stainless steel grade may have specific requirements. Therefore, it is recommended to refer to the manufacturer's guidelines and seek professional advice for optimal results.

- Q: Are stainless steel sheets resistant to stress corrosion cracking?

- Yes, stainless steel sheets are generally resistant to stress corrosion cracking. This is due to their high chromium and nickel content, which provides excellent corrosion resistance properties. Stress corrosion cracking is a type of corrosion that occurs under tensile stress in a corrosive environment. Stainless steel sheets are alloyed with elements that form a passive protective layer on the surface, making them highly resistant to corrosion and preventing stress corrosion cracking. However, it is important to note that the resistance to stress corrosion cracking can vary depending on the specific grade of stainless steel and the environmental conditions it is exposed to. Therefore, it is recommended to consult the manufacturer or refer to corrosion resistance charts to ensure the appropriate stainless steel grade is selected for specific applications.

- Q: What are the different types of stainless steel sheet finishes available?

- There are several different types of stainless steel sheet finishes available, each with its own unique characteristics and applications. Some of the most common finishes include: 1. No. 1 Finish: This is the most basic type of stainless steel sheet finish, also known as hot rolled or annealed and pickled finish. It has a rough, dull appearance with a non-reflective surface. It is commonly used in industrial applications where aesthetics are not a primary concern. 2. No. 2B Finish: This is a smooth, semi-reflective finish that is achieved by cold rolling, annealing, and pickling. It has a slightly glossy appearance and is commonly used for applications where a moderate level of corrosion resistance is required. 3. No. 4 Finish: This finish is achieved by polishing the stainless steel sheet with a fine abrasive material. It has a brushed appearance with a low gloss finish. It is often used in architectural and decorative applications, such as kitchen appliances, countertops, and elevator panels. 4. No. 8 Finish: Also known as a mirror finish, this is the most reflective stainless steel sheet finish available. It is achieved by polishing the surface with progressively finer grits until a mirror-like finish is achieved. It is commonly used in decorative applications, such as architectural accents, signage, and ornamental pieces. 5. Satin Finish: This finish has a smooth, satin-like appearance with a low to medium gloss level. It is achieved by using a combination of brushing and polishing techniques. It is often used in applications where a balance between aesthetics and functionality is desired, such as kitchen equipment, sanitary appliances, and automotive trim. 6. Bead Blasted Finish: This finish is achieved by blasting the surface of the stainless steel sheet with glass beads at high pressure. It creates a uniform, matte appearance with a subtle texture. It is commonly used in architectural and interior design applications, such as wall panels, elevator doors, and furniture. 7. Embossed Finish: This finish is achieved by imprinting a pattern onto the surface of the stainless steel sheet using a mechanical process. It creates a textured appearance that can range from subtle to dramatic, depending on the pattern. It is often used in decorative applications, such as wall cladding, signage, and decorative panels. These are just a few examples of the different types of stainless steel sheet finishes available. The choice of finish depends on the specific requirements of the application, including aesthetics, corrosion resistance, and functionality.

- Q: Are stainless steel sheets suitable for architectural wire mesh?

- Yes, stainless steel sheets are suitable for architectural wire mesh. Stainless steel is a durable and corrosion-resistant material, making it ideal for outdoor applications. It provides strength and stability to the wire mesh, ensuring longevity and aesthetic appeal in architectural designs.

- Q: Can stainless steel sheets be used for food packaging equipment?

- Yes, stainless steel sheets can be used for food packaging equipment. Stainless steel is a popular material choice for food processing and packaging equipment due to its durability, corrosion resistance, and hygienic properties. It is non-reactive, which means it does not interact with the food, ensuring that the quality and taste of the food remain intact. Stainless steel sheets can be easily cleaned and sanitized, making them suitable for use in food packaging equipment where cleanliness and hygiene are of utmost importance. Additionally, stainless steel has a smooth surface, which makes it easy to handle and prevents food particles from sticking to the equipment. Overall, stainless steel sheets are a reliable and safe option for food packaging equipment.

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- To prevent pitting or crevice corrosion on stainless steel sheets, there are several measures that can be taken: 1. Proper alloy selection: Choosing the right grade of stainless steel is crucial. Grades with higher levels of chromium, molybdenum, and nickel provide better resistance to corrosion. 2. Surface finishing: Ensuring a smooth and clean surface is essential to prevent corrosion. Rough surfaces or scratches can act as initiation sites for corrosion. Polishing or electropolishing the stainless steel sheets can help create a smoother surface. 3. Regular cleaning and maintenance: Regular cleaning using mild detergents and non-abrasive cleaners is important to remove contaminants that may corrode the stainless steel sheets. It is also necessary to avoid using chlorine-based cleaners or abrasive materials that can damage the protective oxide layer. 4. Avoiding stagnant conditions: Pitting and crevice corrosion are often intensified in stagnant environments. Ensuring proper drainage and avoiding the accumulation of stagnant water or debris can help prevent this type of corrosion. 5. Control of environmental factors: Stainless steel sheets should be protected from exposure to aggressive chemicals, such as chloride-containing solutions or acidic substances. Proper ventilation and humidity control can also help reduce the risk of corrosion. 6. Use of protective coatings: Applying protective coatings, such as paints or passivation treatments, can provide an additional layer of protection against pitting and crevice corrosion. 7. Regular inspections: Conducting regular inspections to detect any signs of corrosion early on can help prevent further damage. Prompt remedial actions, such as repairing damaged coatings or addressing any drainage issues, can prevent the spread of corrosion. By following these preventive measures, the risk of pitting or crevice corrosion on stainless steel sheets can be significantly reduced, ensuring their longevity and maintaining their aesthetic appeal.

Send your message to us

Cold Rolled Stainless Steel sheets NO.2B Finish Grade 316L 4mm thickness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords