Stainless Steel Sheets,Cold Rolled Stainless Steel Sheets Grade 316L NO.2B Finish For Wholesale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

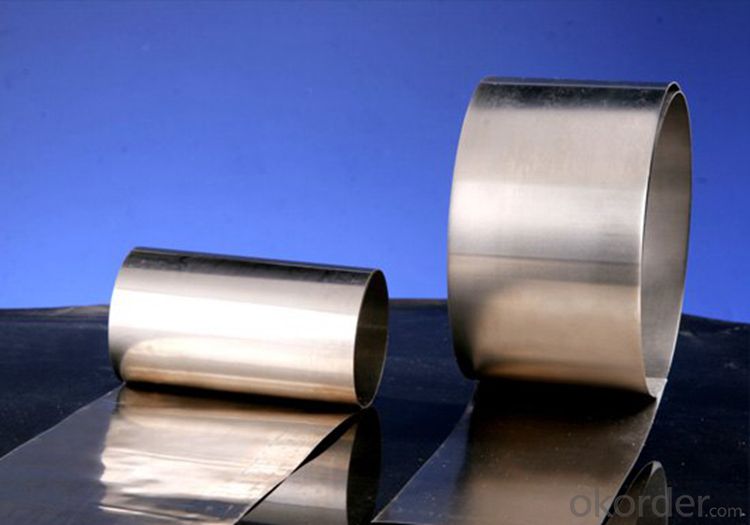

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How do you restore the shine on a stainless steel sheet?

- To restore the shine on a stainless steel sheet, you can follow a few simple steps. First, make sure the surface is clean by wiping away any dirt or debris using a soft cloth or sponge and a mild detergent mixed with warm water. Rinse off the soap residue and dry the sheet thoroughly. Next, apply a small amount of stainless steel cleaner or polish to a clean, soft cloth. Gently rub the cleaner in a circular motion onto the stainless steel sheet, focusing on any areas with visible marks or dullness. Be sure to follow the manufacturer's instructions for the cleaner or polish you are using. After applying the cleaner, let it sit on the surface for a few minutes to allow it to work its magic. Then, using a clean portion of the cloth, buff the stainless steel sheet using circular motions until the shine starts to appear. Continue this process until you are satisfied with the results. If you don't have a specialized stainless steel cleaner or polish, you can also use some household items to restore the shine. For example, you can mix baking soda with water to form a paste and apply it to the sheet. Gently rub the paste onto the surface using a soft cloth and rinse it off thoroughly. Additionally, you can use vinegar or lemon juice to remove any stains or spots. Apply a small amount of vinegar or lemon juice to a cloth and rub it onto the stainless steel sheet, then rinse it off and dry it thoroughly. Remember to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will ensure that it doesn't cause any damage or discoloration.

- Q: Can stainless steel sheets be used for architectural cladding?

- Yes, stainless steel sheets can be used for architectural cladding. Stainless steel is a popular choice for architectural cladding due to its durability, corrosion resistance, and aesthetic appeal. It provides a sleek and modern look to buildings while also offering a long-lasting and low-maintenance solution for exterior cladding applications.

- Q: How do you prevent distortion when welding stainless steel sheets?

- In order to prevent distortion while welding stainless steel sheets, it is important to follow several key steps and precautions: 1. Begin by ensuring that the stainless steel sheets are thoroughly cleaned and free from any contaminants, such as oil, grease, or dirt. Use an appropriate solvent or degreaser to clean the surfaces before welding. This will help to avoid trapping impurities in the weld, which can cause distortion. 2. Accurate fit-up of the stainless steel sheets is crucial to minimize distortion. Make sure that the edges of the sheets are properly aligned and that there are no gaps or misalignments. Proper clamping or tacking can also help to maintain the correct position of the sheets during welding. 3. Controlling the heat input is essential to prevent excessive distortion. Use the appropriate welding technique, such as TIG or MIG, to control the heat. Avoid overheating the stainless steel sheets, as this can lead to warping and distortion. It is important to maintain a consistent and controlled heat input throughout the welding process. 4. Plan the weld sequence properly to minimize distortion. Start from the center and work outward in a balanced manner to distribute the heat evenly. This will prevent localized heating, which can cause distortion. Alternating between sides and allowing each weld to cool before moving to the next one can also help reduce distortion. 5. Choose the right welding technique and parameters. For example, using a lower heat input, slower travel speed, and smaller weld bead can minimize distortion. Additionally, using a backstep technique, where the weld travels in a forward and backward motion, can help distribute the heat and reduce distortion. 6. Consider preheating the stainless steel sheets to reduce the temperature gradient and minimize distortion. Ensure that the preheating temperature is within the recommended range for the specific stainless steel grade. After welding, it is advisable to perform post-weld treatment, such as stress relieving, to minimize residual stresses that can lead to distortion. By following these steps and precautions, it is possible to significantly reduce distortion when welding stainless steel sheets. However, it is important to note that each welding process and stainless steel grade may have specific requirements. Therefore, it is recommended to refer to the manufacturer's guidelines and seek professional advice for optimal results.

- Q: Are stainless steel sheets resistant to pitting corrosion?

- Stainless steel sheets possess resistance against pitting corrosion. Pitting corrosion is a localized type of corrosion that occurs in specific regions, causing small pits or holes to form on the surface of the metal. Stainless steel sheets are manufactured with a significant amount of chromium, which generates a passive oxide layer on the surface, thus providing exceptional corrosion resistance. This oxide layer functions as a protective barrier, safeguarding the metal against pitting corrosion. Moreover, stainless steel comprises additional alloying elements like nickel and molybdenum, which further augment its resistance to pitting corrosion. Consequently, stainless steel sheets exhibit a high level of resistance to pitting corrosion and are extensively used in industries where corrosion resistance is of utmost importance, such as construction, automotive, and food processing.

- Q: How do I remove stains or marks from stainless steel sheets?

- To remove stains or marks from stainless steel sheets, you can follow these simple steps: 1. Start by cleaning the stainless steel surface with a mild detergent or dish soap and warm water. Gently scrub the affected area using a soft cloth or sponge. Rinse thoroughly with clean water and dry with a clean towel. 2. If the stain persists, you can try using white vinegar. Dampen a cloth or sponge with vinegar and gently rub the stained area. Vinegar's acidic properties can help break down the stains. Rinse the surface with water and dry it thoroughly. 3. For tougher stains or marks, you can create a paste using baking soda and water. Apply the paste to the affected area and gently rub it in using a soft cloth or sponge. Let it sit for a few minutes, then rinse with water and dry thoroughly. 4. If the above methods do not work, you can try using a stainless steel cleaner specifically designed for removing stains or marks. Follow the instructions on the cleaner's packaging for best results. Remember to rinse the surface thoroughly and dry it completely after using a commercial cleaner. 5. It is important to avoid using abrasive cleaners, steel wool, or harsh chemicals on stainless steel sheets as they can scratch or damage the surface. Also, always test any cleaning method or product on a small, inconspicuous area before applying it to the entire surface. By following these steps and using the appropriate cleaning methods, you should be able to effectively remove stains or marks from stainless steel sheets and restore their original shine and appearance.

- Q: Are stainless steel sheets suitable for elevator doors?

- Yes, stainless steel sheets are suitable for elevator doors. Stainless steel is a popular choice for elevator doors due to its durability, corrosion resistance, and aesthetic appeal. Elevator doors are subject to constant use and exposure to various elements, making stainless steel an ideal material as it does not rust or corrode easily. Additionally, stainless steel sheets can be easily maintained and cleaned, ensuring a long-lasting and visually pleasing appearance. The versatility of stainless steel also allows for customization in terms of finishes, textures, and patterns, allowing elevator doors to be designed to match the desired aesthetic of the building or space. Overall, stainless steel sheets are a reliable and suitable choice for elevator doors.

- Q: What are the different types of perforated finishes available for stainless steel sheets?

- Some of the different types of perforated finishes available for stainless steel sheets include round, square, slotted, and decorative patterns. These finishes can be customized to meet specific design requirements and are commonly used in architectural, industrial, and decorative applications.

- Q: Can stainless steel sheets be used for food packaging or containers?

- Food packaging or containers can indeed utilize stainless steel sheets. The food industry widely employs stainless steel due to its numerous advantageous qualities. Its corrosion resistance guarantees that the food will not react with the container, ensuring safety for consumption. Moreover, stainless steel is highly durable, making it appropriate for long-term utilization in food packaging or containers. It is also effortless to clean and maintain, meeting the necessary hygiene standards. Furthermore, stainless steel containers or packaging can withstand extreme temperature changes, making them suitable for diverse food storage and transportation requirements. All in all, stainless steel sheets are a dependable and secure option for food packaging or containers.

- Q: How do I prevent stress relaxation on stainless steel sheets?

- Stainless steel sheets undergo stress relaxation when exposed to high temperatures or constant stress. To prevent stress relaxation in stainless steel sheets, the following measures can be taken: 1. Carefully choose the stainless steel grade: Different grades of stainless steel have different resistance to stress relaxation. Opt for a grade with high resistance, such as austenitic stainless steels like Type 304 or Type 316. 2. Avoid excessive temperatures: Operate the stainless steel sheets within the recommended temperature range. Exposing them to temperatures beyond this range can accelerate stress relaxation. Ensure that the operating temperature remains within the permissible limits. 3. Control stress levels: Minimize stress during fabrication and installation. Do not excessively bend, stretch, or deform the material, as this introduces stress. Properly design and fabricate components to reduce stress concentration points. 4. Consider post-weld heat treatment: If the stainless steel sheets are welded, consider performing heat treatment after welding. This involves subjecting the welded area to controlled heating and cooling cycles to relieve residual stresses and minimize the potential for stress relaxation. 5. Reduce exposure to aggressive environments: While stainless steel sheets are corrosion-resistant, exposure to aggressive chemicals or environments can accelerate stress relaxation. Avoid prolonged exposure to corrosive substances or environments that can compromise the material's integrity and cause stress relaxation. 6. Regularly inspect and maintain: Periodically inspect the stainless steel sheets for signs of stress relaxation, such as deformation, cracks, or dimensional changes. Regular maintenance and timely repairs can help identify and address any issues before they worsen. 7. Seek advice from experts: If unsure about preventing stress relaxation in stainless steel sheets, consult metallurgical experts or stainless steel manufacturers. They can provide guidance on the best practices and materials to ensure long-term performance and prevent stress relaxation. By implementing these preventive measures, the risk of stress relaxation in stainless steel sheets can be significantly reduced. This ensures their durability and maintains their structural integrity over time.

- Q: Are stainless steel sheets scratch-resistant?

- Stainless steel sheets, in general, have the ability to resist scratches. The durability and scratch-resistant nature of stainless steel make it a suitable material for different uses, such as kitchen appliances, countertops, and decorations. Nevertheless, it is crucial to bear in mind that even though stainless steel exhibits high resistance against scratches, it is not entirely impervious to them. The surface of stainless steel sheets can still be scratched or marked if sharp objects or abrasive materials are used, particularly with excessive force or repeated contact. By regularly maintaining and properly caring for stainless steel sheets, the visibility of scratches can be minimized, ensuring they remain in their best condition.

Send your message to us

Stainless Steel Sheets,Cold Rolled Stainless Steel Sheets Grade 316L NO.2B Finish For Wholesale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords