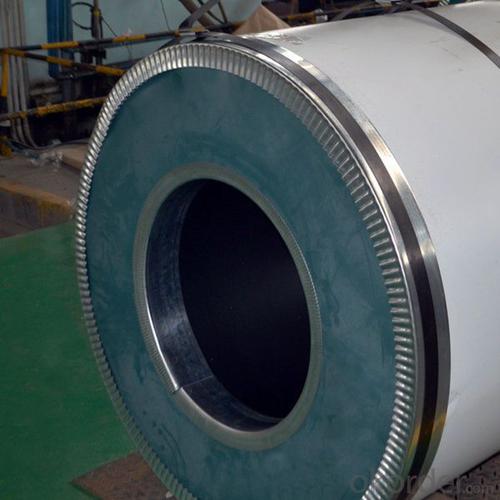

Cold Rolled Stainless Steel Sheets Grade 316 NO.2B Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

- Q: Stainless steel plate glued to tiles, what glue?

- In the choice of ceramic and metal bonding, customers will take into account whether the transparent and heat-resistant properties, metal is silver white, except for a few special colors, is solid at normal temperature (except mercury). Metals generally have good ductility, electrical conductivity, heat resistance (which are related to metal is a metal crystal). Ceramic stability, acid and alkali resistance, corrosion resistance, high temperature resistance, good insulation, high hardness.

- Q: Can stainless steel sheets be used for elevator mirror panels?

- Yes, stainless steel sheets can be used for elevator mirror panels. Stainless steel is a durable and corrosion-resistant material that is commonly used in elevator design and construction. It is also highly reflective, making it an ideal choice for mirror panels. Stainless steel mirror panels not only provide a sleek and modern aesthetic to elevators but also offer excellent durability and ease of maintenance. Additionally, stainless steel can withstand the wear and tear of constant use, making it a reliable and long-lasting material for elevator mirror panels.

- Q: 304 stainless steel plate surface quality inspection method which has several?

- 304 stainless steel surface quality of pickling process mainly depends on the heat treatment, surface oxidation Pihou formation if heat treatment before a process, or organization is not uniform, with acid does not improve the surface smoothness and uniformity. Therefore, attention should be paid to heat treatment or surface cleaning prior to heat treatment.

- Q: Can stainless steel sheets be used for medical sterilization equipment?

- Yes, stainless steel sheets can be used for medical sterilization equipment. Stainless steel is commonly used in the healthcare industry due to its excellent corrosion resistance, durability, and ease of cleaning. It can withstand high temperatures and harsh cleaning agents used in sterilization processes, making it an ideal material for medical equipment that requires frequent sterilization.

- Q: Are stainless steel sheets resistant to UV rays?

- Yes, stainless steel sheets are resistant to UV rays. Stainless steel is known for its durability and corrosion resistance, and this extends to its ability to withstand exposure to UV rays. The chromium content in stainless steel forms a protective oxide layer on the surface, which helps prevent the metal from oxidizing or corroding when exposed to sunlight. This oxide layer acts as a barrier that shields the stainless steel from UV rays, making it highly resistant to the damaging effects of prolonged sun exposure. Therefore, stainless steel sheets are an excellent choice for outdoor applications where UV resistance is a requirement, such as roofing, cladding, and architectural elements.

- Q: Can stainless steel sheets be used in chemical processing plants?

- Chemical processing plants can utilize stainless steel sheets due to their high resistance to corrosion, which makes them an ideal material for environments with chemical exposure. Stainless steel is capable of enduring exposure to a wide range of chemicals, including acids, alkalis, and solvents, without deteriorating or reacting with them. Furthermore, stainless steel sheets are easily cleaned and maintained, ensuring that they adhere to the stringent hygiene and safety standards demanded in chemical processing plants. Additionally, stainless steel possesses exceptional strength and durability, making it suitable for various applications within the facility, such as tanks, piping, pressure vessels, and heat exchangers. In conclusion, stainless steel sheets are a dependable and versatile option for implementation in chemical processing plants.

- Q: Can stainless steel sheets be used for elevator handrails?

- Indeed, elevator handrails can utilize stainless steel sheets. The utilization of stainless steel for handrails is prevalent owing to its endurance, robustness, and immunity to rust. Elevator handrails endure incessant usage and exposure to diverse elements, rendering stainless steel an exemplary selection. Moreover, stainless steel can be effortlessly cleansed and upheld, guaranteeing a sanitary and visually pleasing atmosphere for elevator occupants.

- Q: What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets depend on several factors such as the grade of stainless steel, thickness of the sheet, and the specific type of bending process being used. Stainless steel sheets are known for their excellent strength and durability, which allows them to be bent to a certain extent without breaking or cracking. In general, stainless steel sheets can be bent to a radius that is at least twice the thickness of the sheet. For example, if the sheet is 1mm thick, it can typically be bent to a minimum radius of 2mm. However, it is important to note that this is just a general guideline and the actual bending limits may vary depending on the specific grade of stainless steel. Certain grades of stainless steel, such as 304 and 316, have higher yield strengths and are more resistant to deformation, making them suitable for more severe bending applications. Thicker sheets also have higher bending limits compared to thinner ones, as they have more material to withstand the bending forces. It is also worth mentioning that the type of bending process used can affect the bending limits of stainless steel sheets. Processes like press brake bending and roll bending are commonly used for bending stainless steel sheets. These processes utilize different techniques and equipment, which can result in varying bending limits. To determine the exact bending limits for a specific grade and thickness of stainless steel sheet, it is best to consult the manufacturer's specifications or seek guidance from a professional metal fabricator. They can provide accurate information and guidance on the bending capabilities of stainless steel sheets for your specific application.

- Q: What is the minimum thickness available for stainless steel sheets?

- The minimum thickness available for stainless steel sheets can vary depending on the specific grade and manufacturer. However, in general, stainless steel sheets are commonly available in thicknesses ranging from 0.4mm to 6mm. Some manufacturers may offer even thinner sheets, such as 0.3mm, for specialized applications. It is important to consult with the supplier or manufacturer to determine the exact minimum thickness available for your specific requirements.

- Q: Are stainless steel sheets fire resistant?

- Stainless steel sheets have excellent fire resistance properties. Due to their high melting point and low thermal conductivity, stainless steel is able to withstand high temperatures for prolonged periods of time without undergoing significant structural changes or losing their strength. This makes stainless steel sheets highly resistant to fire and heat damage. Additionally, stainless steel does not release toxic fumes when exposed to fire, which further enhances its safety in fire-prone environments. As a result, stainless steel sheets are commonly used in applications where fire resistance is a critical requirement, such as in the construction of fire doors, fire escapes, and fire-resistant enclosures.

Send your message to us

Cold Rolled Stainless Steel Sheets Grade 316 NO.2B Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords