Cold Rolled Stainless Steel NO.2B Finish Grade 316L Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 5 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

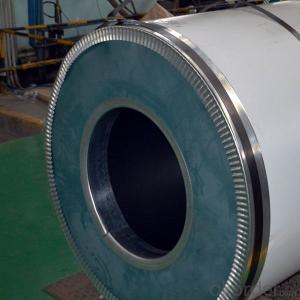

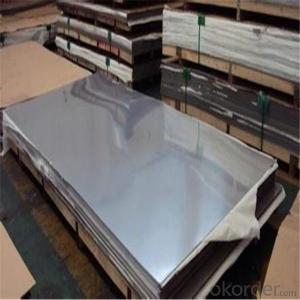

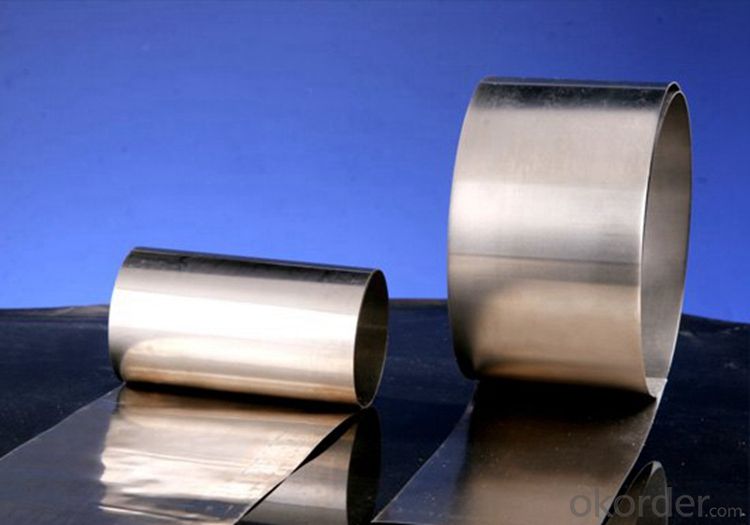

Detail picture

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How do you prevent fingerprints and smudges on stainless steel sheets?

- To prevent fingerprints and smudges on stainless steel sheets, you can use the following methods: 1. Clean with a microfiber cloth: Use a soft microfiber cloth to wipe down the stainless steel surface regularly. This will help remove any fingerprints or smudges quickly without leaving scratches. 2. Use a mild detergent: Mix a few drops of mild dish soap with warm water and dampen the microfiber cloth. Gently wipe the stainless steel surface in the direction of the grain, then rinse and dry with a clean cloth. 3. Apply stainless steel cleaner: There are specific stainless steel cleaners available in the market. Follow the instructions on the product and apply it to the surface using a soft cloth. This cleaner will help repel fingerprints and leave a protective coating on the stainless steel. 4. Avoid harsh cleaners and abrasive materials: Avoid using abrasive cleaning pads, steel wool, or harsh chemicals as they can scratch the stainless steel surface. Stick to gentle cleaning methods to maintain its shine. 5. Use gloves: When handling stainless steel sheets, wear gloves to prevent leaving fingerprints or smudges on the surface. By following these preventive measures, you can keep stainless steel sheets free from fingerprints and smudges, ensuring a clean and polished appearance.

- Q: How do you remove scratches from stainless steel sheets?

- To remove scratches from stainless steel sheets, there are a few methods you can try. First, you can start by using a non-abrasive cleaner or a mild detergent mixed with warm water. Apply the solution to the scratched area using a soft cloth or sponge, and gently rub in a circular motion. Rinse the area thoroughly and dry it with a clean cloth. If the scratches are still visible, you can try using a stainless steel scratch removal kit. These kits often contain a polishing compound specifically designed for stainless steel. Apply the compound to the scratched area and use a soft cloth to buff the surface in the direction of the grain. Continue buffing until the scratches are no longer visible. For deeper scratches, you may need to use a fine-grit sandpaper or a stainless steel scratch repair pen. Start by lightly sanding the scratched area in the direction of the grain. Be careful not to apply too much pressure, as this can damage the surface. After sanding, clean the area thoroughly and use a polishing compound to restore the shine. It's important to note that these methods may not completely remove deep scratches, and in some cases, a professional repair may be necessary. Additionally, always test any cleaning or repair method on a small, inconspicuous area before applying it to the entire surface to ensure it does not cause further damage.

- Q: Can stainless steel sheets be used for outdoor railings?

- Yes, stainless steel sheets can be used for outdoor railings. Stainless steel is a popular choice for outdoor applications due to its durability and resistance to corrosion. It is able to withstand exposure to various weather conditions, such as rain, snow, and sunlight, without deteriorating or rusting. Stainless steel railings provide a sleek and modern look to outdoor spaces, while also offering strength and stability. Additionally, stainless steel is low maintenance and easy to clean, making it an ideal material for outdoor railings that may be subjected to dirt, dust, or other debris. Overall, stainless steel sheets are an excellent choice for outdoor railings, offering both aesthetic appeal and long-lasting performance.

- Q: What are the features of stainless steel plates?

- Can withstand oxalic acid, sulfuric acid iron sulfate, nitrate, nitrate acid and hydrofluoric acid, sulfuric acid copper sulfate, phosphoric acid, formic acid and acetic acid and various acid corrosion, widely used in chemical, food, medicine, papermaking, petroleum, atomic energy industry, as well as construction, kitchen utensils, cutlery, household appliances, vehicles of all kinds of parts.

- Q: What is the difference between hot rolled and cold rolled stainless steel sheets?

- Hot rolled and cold rolled stainless steel sheets differ in their manufacturing process, resulting in distinctive characteristics and properties. Hot rolled stainless steel sheets are manufactured by passing the stainless steel through a series of rollers at a high temperature. This process results in a thicker and rougher surface compared to cold rolled sheets. Hot rolling allows for faster production and is generally more cost-effective. However, the rougher surface may require additional processing, such as grinding or polishing, to achieve the desired finish. On the other hand, cold rolled stainless steel sheets are manufactured by cooling the hot rolled sheets and then annealing them in a controlled environment. This process improves the surface finish, resulting in a smoother and more uniform appearance. Cold rolling also allows for tighter tolerances and greater strength, making it suitable for applications that require precise dimensions and superior mechanical properties. In terms of strength and hardness, cold rolled stainless steel sheets generally exhibit greater strength and hardness compared to hot rolled sheets. This is due to the strain hardening that occurs during the cold rolling process. Cold rolled sheets are also less susceptible to deformation and warping, making them ideal for applications where flatness is critical. In summary, the main differences between hot rolled and cold rolled stainless steel sheets lie in their manufacturing process, surface finish, dimensional tolerance, and mechanical properties. Hot rolled sheets are thicker and have a rougher surface, while cold rolled sheets are thinner, smoother, and exhibit greater strength and hardness. The choice between the two depends on the specific requirements of the application and the desired aesthetic and functional characteristics.

- Q: Are stainless steel sheets suitable for roofing?

- Yes, stainless steel sheets are suitable for roofing. They have excellent durability, corrosion resistance, and can withstand extreme weather conditions. Additionally, their sleek appearance adds aesthetic value to any building.

- Q: How do you put the mirror panel on the stainless steel panel?

- Stainless steel hot rolled plate mirror polishing (mirror, polishing)In recent years, more and more requirements for polishing of stainless steel hot rolled plate, and even mirror polishing have been demanded. The treatment of hot rolled plate is quite different from that of cold rolled plate, and the whole process is more complicated and difficult to handle than cold rolled plate.

- Q: Can stainless steel sheets be cut or shaped?

- Yes, stainless steel sheets can be cut or shaped using various methods such as shearing, laser cutting, plasma cutting, or forming processes like bending, rolling, or stamping.

- Q: Can stainless steel sheets be used for heat shields?

- Yes, stainless steel sheets can be used for heat shields. Stainless steel is known for its excellent heat resistance and durability, making it an ideal material for heat shields in various applications.

- Q: Can stainless steel sheets be used for medical instruments?

- Yes, stainless steel sheets can be used for medical instruments. Stainless steel is a common material choice in the medical industry due to its excellent corrosion resistance, durability, and ease of sterilization. It is widely used in various medical instruments such as surgical tools, implants, and equipment due to its hygienic properties and ability to withstand harsh cleaning and sterilization processes.

Send your message to us

Cold Rolled Stainless Steel NO.2B Finish Grade 316L Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords