201 304 316 316l 2205 hard Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Good quality, competitive price, in time delivery and best service.

Commidity | Factory Cold Rolled 201 304 316 316l 2205 hard Stainless Steel Sheet |

Thickness | 0.1-3.0 mm |

Width | 1000—2000mm or as your required |

Length | 1000—6000 or as your required |

Technique | Cold rolled and hot rolled |

Surface finish | 2B, 8K, NO.3 , NO.4, NO.1 , HL |

Standard | ASTM, AISI , SUS, JIS , EN, DIN, |

Surface color | Natural color |

Delivery terms | FOB , CFR , CIF |

Delivery time | 7-15 days after received deposit |

Loading port | Shanghai |

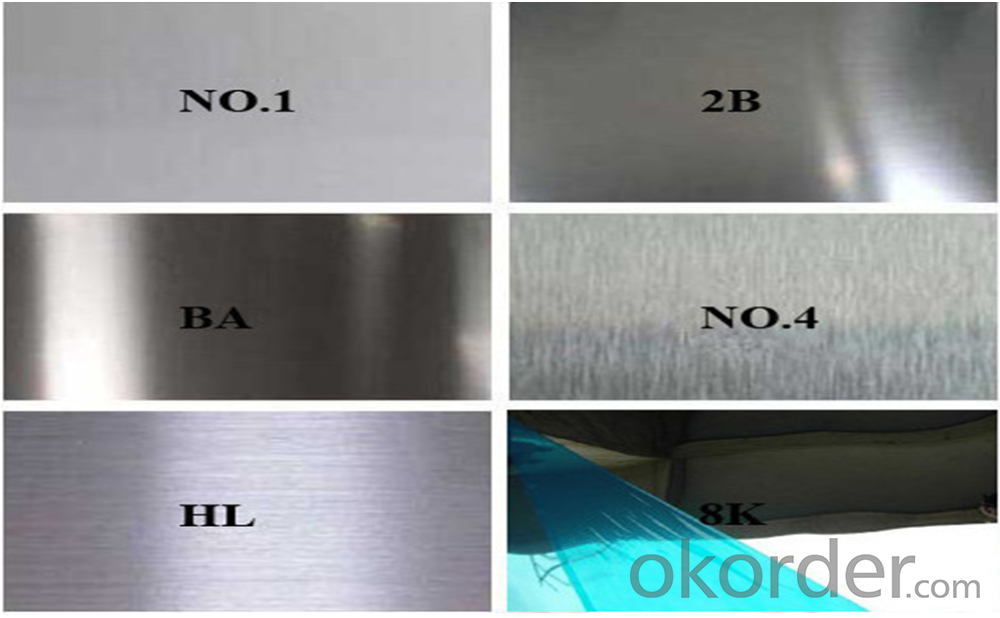

| Surface | Definition | Application |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2B | Those finished, after cold rolling, by heat treatment,pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry,Construction material, Kitchen utensils. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction,Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size | Building Construction. |

| BA(No.6) | Those processed with bright heat treatment after cold rolling. | Kitchen utensils. Electric equipment,Building construction. |

| Mirror(No.8) | Shinning like a mirror | Building construction |

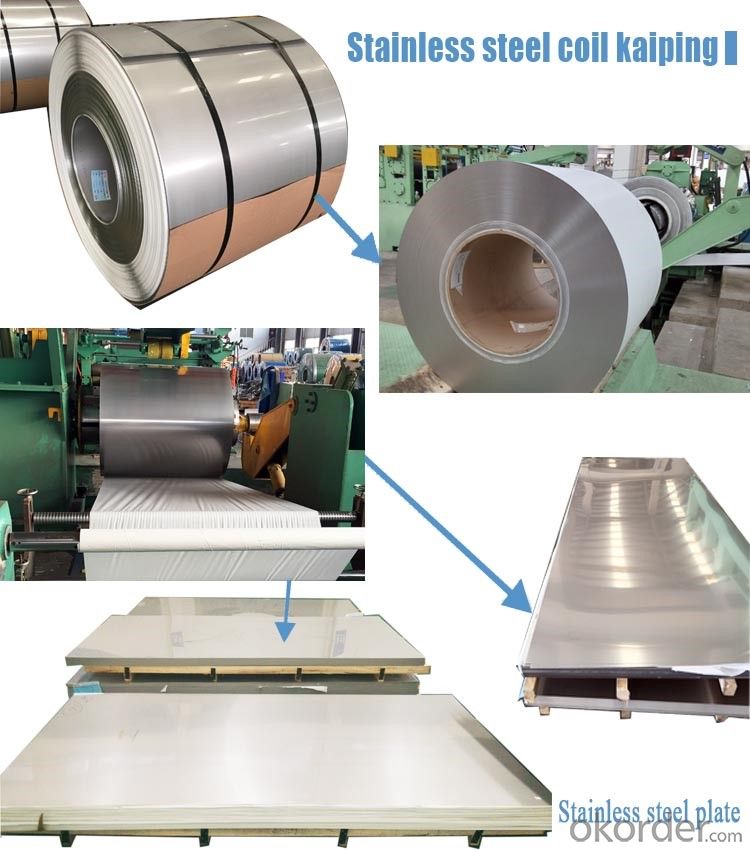

Production Flow

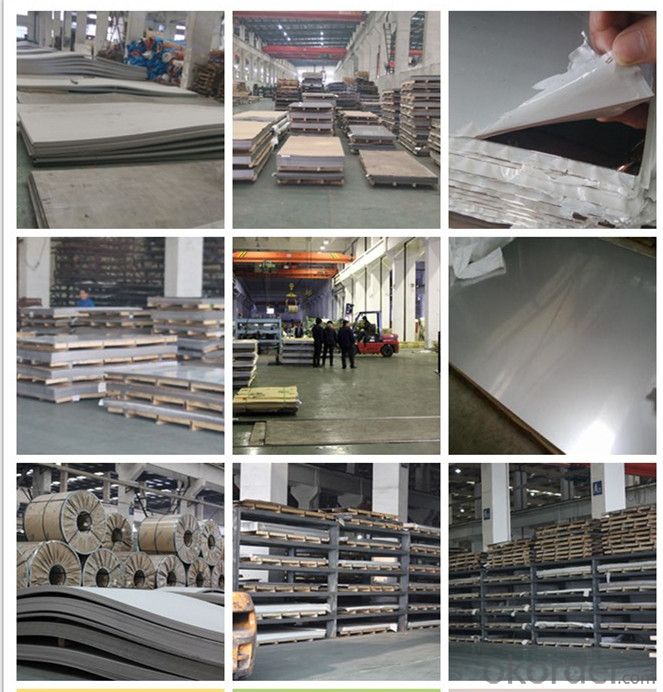

WUXI AOXIANG METAL PRODUCTS CO.,LTD,stainless steel products manufacturer and trading company in China,Our business scope is stainless steel coil/ sheet/ circle/ strip of 410/ 430/ 409L/ 201/202/304/321/316/316L/310S/2205/2507/904L type.

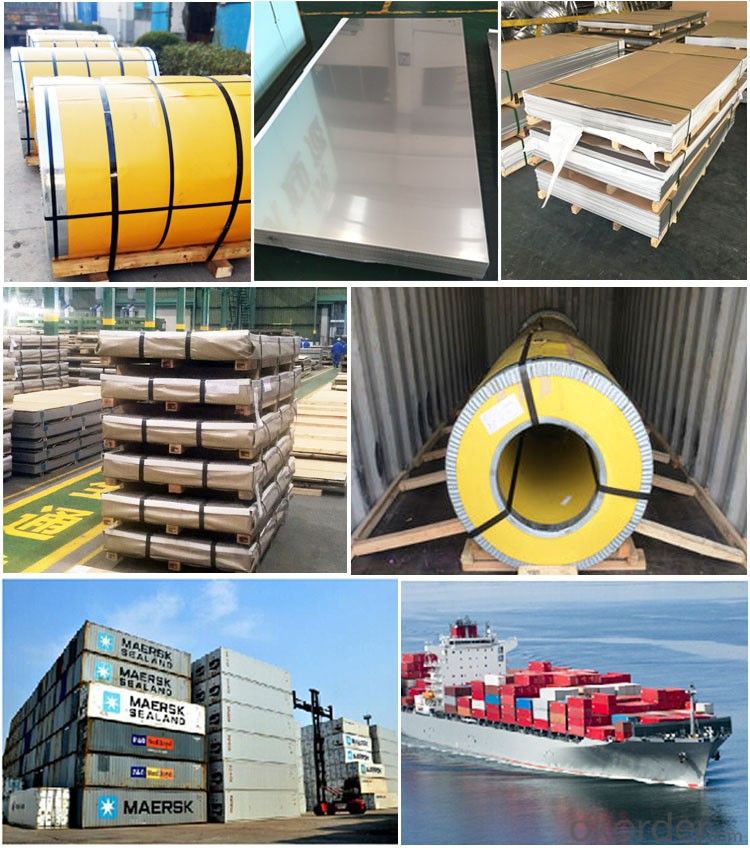

Packaging & Shipping

0.3mm-3mm Thickness Cold Rolled 304 316 316l Stainless Steel Sheet standard export sea-worthy package,covered with PVC ,and wooden case or costomize package.

0.3mm-3mm Thickness Cold Rolled 304 316 316l Stainless Steel Sheet standard export sea-worthy package,covered with PVC ,and wooden case or costomize package.

- Q: What is the price per square foot for stainless steel sheets?

- The price per square foot for stainless steel sheets can vary depending on various factors such as the grade, thickness, finish, and supplier. On average, stainless steel sheets can range from $3 to $10 per square foot. However, high-quality and specialty stainless steel sheets can be priced higher, reaching up to $20 or more per square foot. It is important to consider these factors and shop around to find the best price for your specific requirements.

- Q: Stainless steel plate glued to tiles, what glue?

- In the choice of ceramic and metal bonding, customers will take into account whether the transparent and heat-resistant properties, metal is silver white, except for a few special colors, is solid at normal temperature (except mercury). Metals generally have good ductility, electrical conductivity, heat resistance (which are related to metal is a metal crystal). Ceramic stability, acid and alkali resistance, corrosion resistance, high temperature resistance, good insulation, high hardness.

- Q: Can stainless steel sheets be used in medical applications?

- Certainly, medical applications can indeed utilize stainless steel sheets. The medical sector favors stainless steel for its remarkable resistance against corrosion, its durability, and its simplicity when it comes to sterilization. It finds extensive employment in medical devices, surgical instruments, and implantable components, as it can endure rigorous sterilization procedures like autoclaving. This capability is pivotal in upholding cleanliness and averting infections. Moreover, stainless steel is biocompatible, signifying that it does not interact negatively with bodily tissues or induce any harm or adverse responses. All in all, stainless steel sheets are an unwavering and adaptable material suitable for a plethora of medical applications.

- Q: Can stainless steel sheets be cut to size?

- Yes, stainless steel sheets can be cut to size. Stainless steel sheets are versatile materials that can be easily customized to fit specific dimensions and requirements. They can be cut using various methods such as plasma cutting, laser cutting, or waterjet cutting. These processes allow for precise and accurate cuts, ensuring that the stainless steel sheet is cut to the desired size without compromising its integrity. Additionally, stainless steel is known for its durability and resistance to corrosion, making it an excellent choice for applications that require cutting and shaping.

- Q: Can stainless steel sheets be used for elevator mirrors or panels?

- Stainless steel sheets are indeed suitable for elevator mirrors or panels. Elevator interiors often opt for stainless steel due to its enduring quality, stylish look, and ability to resist corrosion and scratches. By utilizing stainless steel sheets, elevator mirrors or panels achieve a contemporary and sophisticated appearance, while also ensuring effortless cleanliness and upkeep. Moreover, stainless steel is a versatile material that can be personalized with diverse finishes like polished, brushed, or textured, amplifying the allure of the elevator interior.

- Q: Are stainless steel sheets suitable for medical equipment or devices?

- Yes, stainless steel sheets are suitable for medical equipment or devices. They possess excellent corrosion resistance, durability, and high strength, making them ideal for use in medical settings. Stainless steel is also easy to clean and maintain, which is crucial for maintaining a sterile environment.

- Q: What are the benefits of using mirror-finish stainless steel sheets?

- Mirror-finish stainless steel sheets offer several benefits. Firstly, they provide a sleek and modern aesthetic appeal, making them a popular choice for interior and architectural design. Additionally, the reflective surface of these sheets creates the illusion of a larger space, making them ideal for small areas. Mirror-finish stainless steel also has superior corrosion resistance, making it a durable option for outdoor applications. The smooth surface is easy to clean and maintain, reducing the need for frequent upkeep. Finally, mirror-finish stainless steel sheets are often used in food processing and medical industries due to their hygienic properties and ability to resist bacterial growth.

- Q: Are stainless steel sheets suitable for roofing?

- Yes, stainless steel sheets are suitable for roofing. They have excellent durability, corrosion resistance, and can withstand extreme weather conditions. Additionally, their sleek appearance adds aesthetic value to any building.

- Q: How do I prevent stress corrosion cracking on stainless steel sheets?

- To prevent stress corrosion cracking on stainless steel sheets, there are several measures you can take: 1. Choose the right stainless steel grade: Use a stainless steel grade that is resistant to stress corrosion cracking (SCC). Common grades like 304 and 316 have good resistance to SCC, but some specific applications may require higher alloyed grades such as duplex or super duplex stainless steels. 2. Avoid exposure to corrosive environments: Limit the exposure of stainless steel sheets to environments that are known to cause stress corrosion cracking, such as chloride-rich or acidic environments. If exposure cannot be avoided, consider using protective coatings or barriers to shield the stainless steel from these corrosive elements. 3. Control applied stress levels: Avoid subjecting the stainless steel sheets to excessive mechanical or thermal stresses. High tensile stresses can promote the initiation and propagation of stress corrosion cracking. Proper design and fabrication techniques should be employed to ensure even stress distribution and minimize stress concentrations. 4. Maintain proper surface condition: Ensure that the stainless steel sheets are free from surface contamination or defects that can act as initiation sites for stress corrosion cracking. Regular cleaning and inspection of the sheets to remove any contaminants or corrosion products is crucial. 5. Use inhibitors or cathodic protection: In certain cases where exposure to corrosive environments is unavoidable, the use of corrosion inhibitors or implementing cathodic protection techniques can help mitigate stress corrosion cracking. These methods work by reducing the corrosive activity on the stainless steel surface. 6. Proper handling and storage: During transportation and storage, care should be taken to avoid excessive bending, vibration, or exposure to corrosive substances. Stainless steel sheets should be stored in a clean and dry environment to prevent any potential surface contamination. Overall, a combination of material selection, environmental control, stress management, surface maintenance, and proper handling can effectively prevent stress corrosion cracking on stainless steel sheets. It is advisable to consult with material experts or engineers to analyze the specific application requirements and recommend the most appropriate preventive measures.

- Q: How do you remove water spots from stainless steel sheets?

- To remove water spots from stainless steel sheets, you can follow these simple steps: 1. Start by thoroughly cleaning the surface with a mild dish soap and warm water solution. This will remove any dirt or grime that may be contributing to the appearance of water spots. 2. Rinse the sheets with clean water and dry them completely using a soft cloth or towel. This step is important to prevent any new water spots from forming during the cleaning process. 3. Next, prepare a solution of equal parts white vinegar and water. Dip a clean cloth or sponge into the solution and wring out any excess liquid. 4. Gently rub the affected areas of the stainless steel sheets with the vinegar solution-soaked cloth or sponge. Be sure to follow the grain of the stainless steel to avoid scratching the surface. 5. After rubbing the water spots, rinse the sheets with clean water and dry them thoroughly once again with a soft cloth or towel. 6. If the water spots persist, you can try using a stainless steel cleaner or polish specifically designed for removing stains and water spots. Follow the instructions provided with the cleaner, and be sure to test it on a small, inconspicuous area first to ensure it does not damage the stainless steel. Remember to always use soft materials and gentle cleaning techniques when dealing with stainless steel to avoid scratching or damaging the surface.

Send your message to us

201 304 316 316l 2205 hard Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords