Cold Rolled Stainless Steel NO.2B Good Quality Steel Coils Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

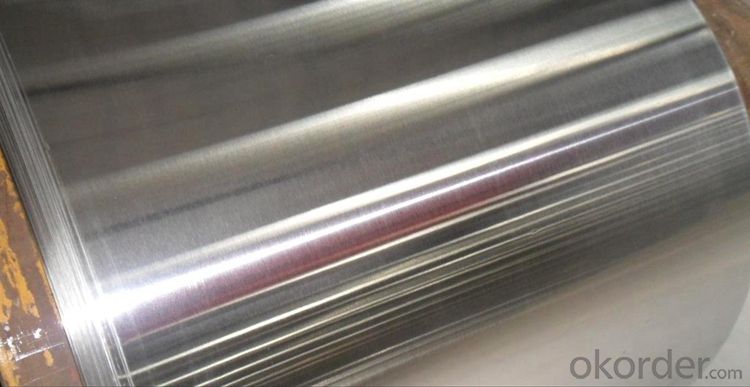

Detail picture for Stainless Steel Coils/Sheets

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Specifications for Stainless Steel Coils/Sheets:

Material | Stainless Steel | |

Standard | AISI, ASTM, JIS,GB,EN,DIN | |

Grade | 304 | |

Technology | Cold Rolled and Hot rolled | |

Form | plate | |

Thickness | 0.3 mm – 8.0mm | |

Width | 1000mm,1219mm,1250mm,1500mm,1524mm,2000mm | |

The sizes or thickness of stainless steel coil can be customized, if you need additional information, please don't hesitate to contact us at anytime. | ||

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: How do you remove scratches from stainless steel sheets?

- There are a few methods you can try to remove scratches from stainless steel sheets. One option is to use a non-abrasive cleaner or stainless steel polish, applying it with a soft cloth and gently rubbing the scratched area in a circular motion. Another method involves making a paste using baking soda and water, applying it to the scratch, and gently rubbing it with a soft cloth. Additionally, you can use a fine-grit sandpaper to lightly buff the scratch in the direction of the grain. Remember to always test these methods on a small, inconspicuous area first to ensure they do not damage the stainless steel.

- Q: What are the different types of stainless steel sheet coatings available?

- A variety of stainless steel sheet coatings are available, each with its own unique properties and benefits. Some commonly used coatings include: 1. Galvanized Coatings: These coatings protect stainless steel sheets from corrosion and rust by applying a layer of zinc. They are ideal for outdoor applications or environments with moisture or chemicals. 2. Powder Coatings: Offering excellent durability and corrosion resistance, powder coatings are a popular choice. They are applied as a dry powder and heated to form a protective layer. They come in various colors and finishes for customization. 3. Electroplating: This process involves depositing a thin layer of another metal, such as chrome, nickel, or zinc, onto the stainless steel sheet. It enhances appearance and improves resistance to corrosion and wear. 4. PVD Coatings: Physical Vapor Deposition (PVD) coatings are created by depositing a thin film onto the stainless steel sheet using a vacuum process. They offer improved hardness, scratch resistance, and color options, making them suitable for architectural or decorative purposes. 5. Organic Coatings: Paints or lacquers can be applied as organic coatings to provide an extra layer of corrosion protection and aesthetic choices. They are commonly used when color matching or branding is important. Each stainless steel sheet coating has its own advantages and is suitable for specific applications. The choice of coating depends on factors such as intended use, desired appearance, and environmental conditions. It is important to carefully consider these factors and seek expert advice to select the most suitable coating for your needs.

- Q: How do I calculate the strength of stainless steel sheets?

- To calculate the strength of stainless steel sheets, you need to consider factors such as the material's tensile strength, yield strength, and thickness. Tensile strength refers to the maximum amount of stress a material can withstand before it breaks, while yield strength is the maximum stress the material can endure without permanent deformation. Additionally, the thickness of the sheet will also affect its overall strength. By referring to the specifications provided by the manufacturer or consulting relevant engineering resources, you can determine the specific strength values for the stainless steel sheets you are working with.

- Q: Can stainless steel sheets be formed into different shapes?

- Yes, stainless steel sheets can be formed into different shapes through processes such as bending, rolling, and stamping.

- Q: Can stainless steel sheets be used for restaurant equipment?

- Certainly! Restaurant equipment can indeed utilize stainless steel sheets. Stainless steel is a highly favored option for restaurant equipment owing to its multitude of advantages. Its durability, resistance to corrosion, and ease of cleaning all contribute to its popularity. By employing stainless steel sheets, restaurant equipment can be crafted into diverse forms and dimensions, fulfilling the particular needs of countertops, sinks, tables, shelves, and food preparation surfaces. Moreover, stainless steel is an exceptionally hygienic substance that does not interact with food or taint it, rendering it perfect for deployment in restaurant environments where cleanliness and food safety are of utmost importance.

- Q: What are the applications of stainless steel sheets in the automotive industry?

- Stainless steel sheets in the automotive industry are used for various applications such as body panels, exhaust systems, fuel tanks, and structural components. They provide excellent corrosion resistance, high strength, and durability, making them ideal for withstanding harsh conditions and ensuring long-lasting performance in vehicles. Additionally, stainless steel sheets can be easily formed and welded, allowing for precise shaping and customization according to the specific requirements of different automotive parts.

- Q: How do you prevent discoloration or staining on stainless steel sheets?

- To prevent discoloration or staining on stainless steel sheets, there are several steps you can take: 1. Regular Cleaning: Clean the stainless steel sheets regularly using mild soap or detergent and warm water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. After cleaning, rinse thoroughly with clean water and dry with a soft cloth to prevent water spots. 2. Avoid Harsh Chemicals: Avoid using harsh chemicals such as bleach, ammonia, or chlorine-based cleaners on stainless steel sheets. These chemicals can cause discoloration or staining. Instead, opt for stainless steel-specific cleaners or natural cleaners like vinegar or lemon juice. 3. Proper Storage: Store stainless steel sheets in a clean and dry environment to avoid exposure to moisture or humidity. Moisture can lead to corrosion or rust, which can cause discoloration. If the sheets are stored outdoors, cover them properly to protect them from rain or snow. 4. Use Protective Coatings: Applying a protective coating or sealant on stainless steel sheets can help prevent discoloration or staining. There are various products available in the market specifically designed for stainless steel protection. Follow the manufacturer's instructions for application and reapplication, if necessary. 5. Avoid Contact with Reactive Metals: Avoid contact between stainless steel sheets and other reactive metals such as iron, copper, or aluminum. When these metals come into contact with stainless steel, a chemical reaction called galvanic corrosion can occur, leading to discoloration and staining. Ensure separation or isolation between stainless steel and reactive metals. 6. Regular Maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration, staining, or damage. Address any issues promptly to prevent further deterioration. If you notice any stubborn stains, use a non-abrasive stainless steel cleaner and a soft cloth to gently rub the affected area in the direction of the grain. By following these preventive measures, you can maintain the appearance and integrity of stainless steel sheets, ensuring they remain free from discoloration or staining for an extended period.

- Q: How do I prevent stress corrosion cracking on stainless steel sheets?

- To prevent stress corrosion cracking on stainless steel sheets, there are several measures you can take: 1. Choose the right stainless steel grade: Use a stainless steel grade that is resistant to stress corrosion cracking (SCC). Common grades like 304 and 316 have good resistance to SCC, but some specific applications may require higher alloyed grades such as duplex or super duplex stainless steels. 2. Avoid exposure to corrosive environments: Limit the exposure of stainless steel sheets to environments that are known to cause stress corrosion cracking, such as chloride-rich or acidic environments. If exposure cannot be avoided, consider using protective coatings or barriers to shield the stainless steel from these corrosive elements. 3. Control applied stress levels: Avoid subjecting the stainless steel sheets to excessive mechanical or thermal stresses. High tensile stresses can promote the initiation and propagation of stress corrosion cracking. Proper design and fabrication techniques should be employed to ensure even stress distribution and minimize stress concentrations. 4. Maintain proper surface condition: Ensure that the stainless steel sheets are free from surface contamination or defects that can act as initiation sites for stress corrosion cracking. Regular cleaning and inspection of the sheets to remove any contaminants or corrosion products is crucial. 5. Use inhibitors or cathodic protection: In certain cases where exposure to corrosive environments is unavoidable, the use of corrosion inhibitors or implementing cathodic protection techniques can help mitigate stress corrosion cracking. These methods work by reducing the corrosive activity on the stainless steel surface. 6. Proper handling and storage: During transportation and storage, care should be taken to avoid excessive bending, vibration, or exposure to corrosive substances. Stainless steel sheets should be stored in a clean and dry environment to prevent any potential surface contamination. Overall, a combination of material selection, environmental control, stress management, surface maintenance, and proper handling can effectively prevent stress corrosion cracking on stainless steel sheets. It is advisable to consult with material experts or engineers to analyze the specific application requirements and recommend the most appropriate preventive measures.

- Q: Can stainless steel sheets be used in high-pressure environments?

- Yes, stainless steel sheets can be used in high-pressure environments. Stainless steel is known for its excellent strength, durability, and corrosion resistance, making it suitable for applications that require withstanding high pressure conditions. The material's ability to resist deformation and maintain its integrity under extreme pressure makes it a preferred choice in industries such as oil and gas, chemical processing, and aerospace.

- Q: Are stainless steel sheets resistant to high-pressure environments?

- Stainless steel sheets exhibit remarkable resistance to high-pressure environments. This material boasts robustness and durability, enabling it to endure the immense force exerted by diverse industrial operations, including hydraulic systems, chemical processing plants, and oil and gas pipelines. Its outstanding tensile strength and capacity to maintain structural integrity even in the face of extreme pressure make it highly esteemed. Moreover, stainless steel also possesses corrosion resistance, further bolstering its suitability for high-pressure settings where exposure to moisture or chemicals is prevalent. Consequently, stainless steel sheets are extensively employed in industries that demand materials capable of withstanding high-pressure circumstances due to their exceptional strength and resistance attributes.

Send your message to us

Cold Rolled Stainless Steel NO.2B Good Quality Steel Coils Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords