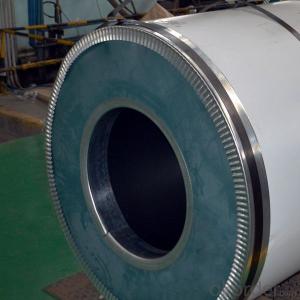

Stainless Steel Coils in Cold Rolled NO.2B Finish Grade 316 with Good Quality from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Packaging & Delivery

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 15-20 days after deposit or according to the order quantity

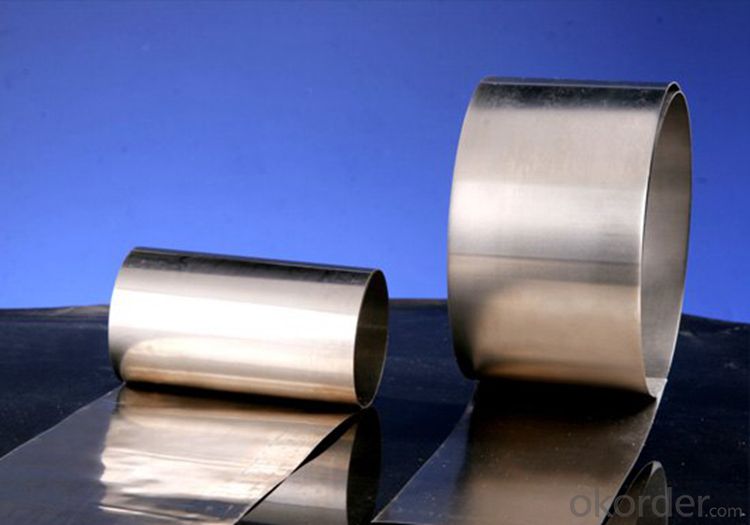

Detail picture of Products:

Application:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What are the different types of stainless steel sheet thicknesses available?

- There is a wide variety of stainless steel sheet thicknesses to choose from, each serving different purposes and applications. The most commonly used thicknesses range from 0.4mm to 3.0mm, with increments of 0.4mm. These sheets are typically utilized in general applications such as construction, automotive parts, and household appliances. For more specialized applications, one can find thinner stainless steel sheets with thicknesses ranging from 0.1mm to 0.3mm. These thinner sheets are commonly employed in industries like electronics, telecommunications, and medical equipment manufacturing, where precise and delicate components are necessary. On the other hand, thicker stainless steel sheets, starting from 3.0mm and going up to 20mm or more, are reserved for heavy-duty applications like industrial machinery, shipbuilding, and construction projects that require exceptional structural integrity and durability. It's important to keep in mind that the available stainless steel sheet thicknesses may vary depending on the manufacturer and the intended use. Moreover, custom thicknesses can be manufactured to meet the specific requirements of a project.

- Q: Are stainless steel sheets suitable for cleanroom applications?

- Indeed, stainless steel sheets prove to be apt for cleanroom applications. The reason lies in the fact that stainless steel boasts exceptional resistance against corrosion, a trait that holds immense importance in cleanroom environments where the utmost cleanliness and hygiene are paramount. Furthermore, stainless steel exhibits remarkable durability and effortless cleanability, rendering it an ideal choice for maintaining cleanliness standards in cleanrooms. Moreover, stainless steel possesses a non-porous nature, thereby preventing the absorption of contaminants and facilitating easy sanitization. Its resistance to chemicals further adds to its suitability for cleanroom applications that involve the use of potent disinfectants or cleaning agents. All in all, stainless steel sheets provide a dependable and hygienic surface for cleanroom applications.

- Q: What are the common uses of stainless steel sheets?

- Stainless steel sheets have a wide range of applications due to their unique properties and versatility. Some of the most common uses include: 1. Construction: Stainless steel sheets are extensively used in the construction industry for roofing, cladding, and facades. They offer excellent durability, corrosion resistance, and a modern aesthetic appeal. 2. Automotive: Stainless steel sheets find applications in the automotive industry for manufacturing various components such as exhaust systems, grilles, trims, and decorative elements. Their resistance to heat, corrosion, and impact makes them ideal for these purposes. 3. Kitchen appliances: Stainless steel sheets are commonly used in the manufacturing of kitchen appliances like refrigerators, ovens, dishwashers, and sinks. Their hygienic properties, resistance to stains, and easy maintenance make them a popular choice for these applications. 4. Food processing: Stainless steel sheets are widely used in the food processing industry due to their non-reactive nature and ease of cleaning. They are used for making equipment such as storage tanks, conveyor systems, work surfaces, and food preparation tables. 5. Medical equipment: Stainless steel sheets are crucial in the manufacturing of medical equipment and devices. They are used for surgical instruments, dental tools, implantable devices, and hospital furniture due to their biocompatibility, corrosion resistance, and ease of sterilization. 6. Aerospace: Stainless steel sheets are utilized in the aerospace industry for constructing aircraft components like fuselage frames, engine parts, and landing gear. Their high strength-to-weight ratio, resistance to extreme temperatures, and corrosion resistance make them suitable for these demanding applications. 7. Energy and power generation: Stainless steel sheets are commonly used in power plants, oil refineries, and chemical processing plants for constructing equipment like heat exchangers, boilers, and storage tanks. Their ability to withstand high temperatures, pressure, and corrosive environments is essential in these industries. 8. Decorative purposes: Stainless steel sheets are also used for decorative purposes in architecture and interior design. They can be used to create unique and modern finishes on walls, ceilings, furniture, and decorative panels. Overall, stainless steel sheets are a versatile material used in various industries due to their exceptional properties like corrosion resistance, durability, hygienic properties, and aesthetic appeal.

- Q: What are the advantages and disadvantages of net drawing stainless steel users?

- The drawing is divided into: stainless steel, oil mill, dry grinding mill, drawing drawing drawing, the drawing effect is the most ideal oil mill, and the appearance is satisfactory!Mirror stainless steel plate making principle is stainless steel plate raw material, with grinding fluid through the polishing equipment in the steel plate surface polishing, make the board surface is smooth and the brightness is as clear as the mirror. Stainless steel mirror panel products are widely used in architectural decoration, elevator decoration, industrial decoration, facilities decoration and other decoration projects.

- Q: How do you prevent staining on stainless steel sheets?

- To prevent staining on stainless steel sheets, it is important to regularly clean and maintain them. This can be done by using non-abrasive cleaners specifically designed for stainless steel, avoiding harsh chemicals and abrasive materials that can scratch the surface. Additionally, wiping away spills or moisture promptly and drying the sheets thoroughly after cleaning can help prevent staining. Using protective coatings or sealants specifically made for stainless steel can also offer an extra layer of protection against staining.

- Q: Are stainless steel sheets resistant to nitric acid?

- Yes, stainless steel sheets are generally resistant to nitric acid. Nitric acid is a strong oxidizing agent that can corrode and dissolve many metals, but stainless steel contains a significant amount of chromium, which forms a protective oxide layer on the surface of the material. This oxide layer acts as a barrier, preventing the nitric acid from coming into direct contact with the stainless steel and thus providing resistance to corrosion. However, it is important to note that the resistance may vary depending on the grade and composition of the stainless steel, as well as the concentration and temperature of the nitric acid.

- Q: Are stainless steel sheets suitable for decorative purposes?

- Yes, stainless steel sheets are suitable for decorative purposes. They offer a sleek and modern aesthetic, are highly durable, and can be customized with various finishes and patterns. Additionally, stainless steel is resistant to corrosion, making it a practical choice for both indoor and outdoor decorative applications.

- Q: Can stainless steel sheets be used in medical equipment?

- Yes, stainless steel sheets can be used in medical equipment. Stainless steel is a popular material choice for medical equipment due to its corrosion resistance, durability, and easy maintenance. It is commonly used in surgical instruments, medical devices, hospital furniture, and other medical applications.

- Q: What are the different shapes available for stainless steel sheets?

- Stainless steel sheets are available in various shapes, including flat sheets, perforated sheets, corrugated sheets, embossed sheets, and diamond plates. These shapes cater to different applications and aesthetic preferences in industries such as construction, automotive, and interior design.

- Q: Are stainless steel sheets good for high-temperature applications?

- Stainless steel sheets prove to be an exceptional choice for applications at high temperatures. With a high melting point that typically ranges from 1400 to 1450 degrees Celsius (2552 to 2642 degrees Fahrenheit), stainless steel becomes suitable for environments with elevated temperatures. Moreover, this type of steel displays remarkable resistance to oxidation when subjected to high temperatures, effectively preventing the formation of scales or rust that could potentially weaken the material. Additionally, stainless steel boasts good thermal conductivity, facilitating efficient heat transfer. These remarkable attributes establish stainless steel sheets as a dependable option for a diverse range of high-temperature applications, such as industrial furnaces, heat exchangers, boilers, and exhaust systems.

Send your message to us

Stainless Steel Coils in Cold Rolled NO.2B Finish Grade 316 with Good Quality from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords