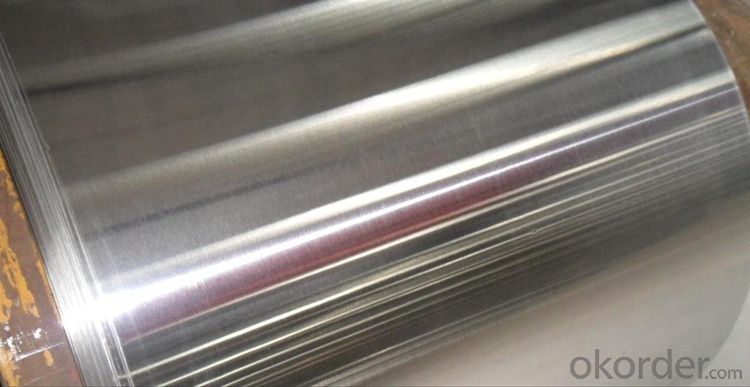

Cold Rolled Stainless Steel Coils,Stainless Steel Plates NO.2B Finish Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Product name: cold roll stainless steel coilcold roll stainless steel coil

Material | Stainless Steel | |

Standard | AISI, ASTM, JIS,GB,EN,DIN | |

Grade | 304 | |

Technology | Cold Rolled and Hot rolled | |

Form | plate | |

Thickness | 0.3 mm – 8.0mm | |

Width | 1000mm,1219mm,1250mm,1500mm,1524mm,2000mm | |

The sizes or thickness of stainless steel coil can be customized, if you need additional information, please don't hesitate to contact us at anytime. | ||

Detail picture for Stainless Steel Coils/Sheets

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: How do you prevent crevice corrosion in stainless steel sheets?

- To prevent crevice corrosion in stainless steel sheets, there are a few key measures that can be taken: 1. Proper design and fabrication: Ensure that the stainless steel sheets are designed and fabricated with smooth surfaces and minimal crevices. This will reduce the potential for stagnant solution entrapment and minimize the risk of crevice corrosion. 2. Regular cleaning and maintenance: Regularly clean the stainless steel sheets to remove any debris or contaminants that can promote crevice corrosion. This can be done using mild detergents or specialized stainless steel cleaners. 3. Avoid exposure to corrosive environments: Limit the exposure of stainless steel sheets to corrosive environments, such as those containing chloride ions (e.g., saltwater). If exposure is unavoidable, consider applying protective coatings or using higher-grade stainless steel alloys that are more resistant to crevice corrosion. 4. Control the environment: Maintain proper environmental conditions, such as controlling temperature, humidity, and pH levels, to minimize the risk of crevice corrosion. Monitoring and controlling these factors can help create a less conducive environment for corrosion to occur. 5. Regular inspections and maintenance: Conduct regular inspections to identify any signs of crevice corrosion, such as discoloration, pitting, or rough surfaces. If any corrosion is detected, take immediate action to remove it and repair the affected area. By implementing these preventive measures, you can significantly reduce the risk of crevice corrosion in stainless steel sheets, ensuring their longevity and performance.

- Q: Are stainless steel sheets suitable for food processing?

- Indeed, stainless steel sheets prove to be an excellent choice for food processing purposes. The food and beverage industry extensively utilizes stainless steel owing to its exceptional properties and hygienic characteristics. Notably, it does not react with food, is highly resistant to corrosion, and does not introduce any taste or smell to the processed food. Moreover, stainless steel is effortless to clean and upkeep, rendering it an optimal selection for food processing machinery, worktops, and various other surfaces. Additionally, it withstands elevated temperatures and effectively resists bacterial proliferation, thereby establishing itself as a reliable and secure material for food processing activities.

- Q: Can stainless steel sheets be used in high-temperature environments?

- Yes, stainless steel sheets can be used in high-temperature environments. Stainless steel is known for its excellent heat resistance properties, making it suitable for various applications in high-temperature environments. The specific grade of stainless steel used and its composition determines its maximum operating temperature. Austenitic stainless steels, such as grades 304 and 316, can withstand temperatures up to 1600°F (870°C) without losing their mechanical strength or corrosion resistance. However, higher alloyed stainless steels, such as grades 309 and 310, are specifically designed to handle even higher temperatures, up to around 2100°F (1150°C). These stainless steel sheets are commonly used in industries like power generation, chemical processing, furnace manufacturing, and aerospace, where exposure to extreme heat is a requirement.

- Q: Can stainless steel sheets be used for column covers?

- Yes, stainless steel sheets can be used for column covers. Stainless steel is a durable and corrosion-resistant material, making it suitable for exterior applications. It provides an attractive and modern finish that can enhance the aesthetic appeal of a building. Stainless steel sheets can be easily fabricated and installed to fit around columns, creating a sleek and seamless appearance. Additionally, stainless steel is low maintenance and easy to clean, making it a practical choice for column covers that are exposed to the elements.

- Q: Can stainless steel sheets be used for pharmaceutical equipment?

- Indeed, pharmaceutical equipment can utilize stainless steel sheets. Stainless steel is highly favored in the pharmaceutical industry due to its remarkable resistance to corrosion, durability, and ease of cleaning. It does not react with other substances and does not emit any detrimental substances that could compromise the quality or purity of pharmaceutical products. Stainless steel sheets can be molded into different forms and sizes to cater to the specific needs of pharmaceutical equipment, including storage tanks, mixing vessels, sterilization devices, and piping systems. Additionally, the sleek surface of stainless steel hinders the buildup of bacteria, rendering it an exceptionally sanitary option for pharmaceutical applications.

- Q: Can stainless steel sheets be used for architectural column covers?

- Yes, stainless steel sheets can be used for architectural column covers. Stainless steel is often chosen for its durability, corrosion resistance, and aesthetic appeal. It can provide a sleek and modern look to architectural structures. Additionally, stainless steel is available in various finishes, such as brushed or polished, allowing for customization and design versatility. Stainless steel sheets can be easily fabricated and installed as column covers, providing a protective and decorative covering for structural columns in architectural projects.

- Q: Can stainless steel sheets be used for magnetic shielding?

- Yes, stainless steel sheets can be used for magnetic shielding to some extent. While stainless steel is not inherently magnetic, it does have some magnetic properties. Stainless steel alloys contain iron, a magnetic material, which allows them to exhibit weak magnetic characteristics. However, the magnetic shielding effectiveness of stainless steel sheets is limited compared to other materials specifically designed for magnetic shielding, such as mu-metal or nickel-iron alloys. These materials have a higher permeability, meaning they can redirect and absorb magnetic fields more effectively than stainless steel. Nonetheless, stainless steel sheets can still provide some level of magnetic shielding, especially in lower intensity magnetic fields. They can help reduce the transmission of magnetic fields from one area to another, which might be useful in certain applications. However, for high-intensity or sensitive magnetic shielding requirements, it is recommended to use specialized magnetic shielding materials for optimum effectiveness.

- Q: Can stainless steel sheets be used for roofing or cladding?

- Yes, stainless steel sheets can be used for roofing or cladding. Stainless steel is a durable and corrosion-resistant material that is well-suited for exterior applications. It offers excellent strength and can withstand harsh weather conditions, making it an ideal choice for roofing or cladding. Additionally, stainless steel has a sleek and modern appearance, which can enhance the aesthetic appeal of a building. Its longevity and low maintenance requirements also make it a cost-effective option in the long run. Overall, stainless steel sheets are a reliable and versatile choice for roofing or cladding projects.

- Q: Are stainless steel sheets suitable for roofing?

- Yes, stainless steel sheets are suitable for roofing. They have excellent durability, corrosion resistance, and can withstand extreme weather conditions. Additionally, their sleek appearance adds aesthetic value to any building.

- Q: Can stainless steel sheets be used for kitchen backsplashes?

- Yes, stainless steel sheets can be used for kitchen backsplashes. Stainless steel is a popular choice for kitchen backsplashes due to its durability, resistance to heat and moisture, and easy maintenance. It provides a sleek and modern look to the kitchen while also protecting the wall from splatters and stains. Additionally, stainless steel sheets are available in various finishes, such as brushed, mirrored, or patterned, allowing homeowners to choose the style that best complements their kitchen design.

Send your message to us

Cold Rolled Stainless Steel Coils,Stainless Steel Plates NO.2B Finish Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords