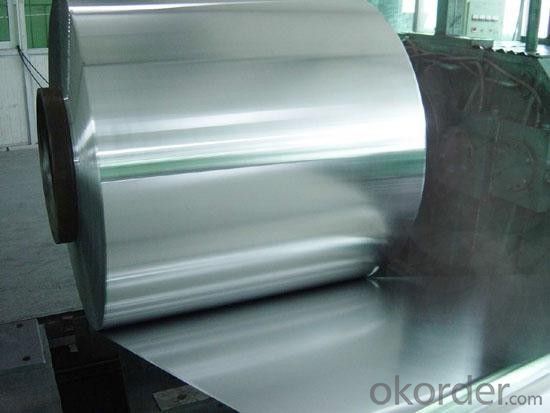

Stainless Steel Sheet and Plate with Polishing Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of stainless steel

304 stainless Steel Plate

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

TISCO stainless Steel Plate 304/NO.1 finished

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

Delivery short and low cost advantage.

Description of stainless steel:

stainless steel plate,hot rolled stainless steel plate,cold rolled stainless steel plate,stainless steel sheet,steel sheet,sheet

Material of stainless steel:

304,304L,309S,310S,316,316L,316Ti,317L,317L,321,347H,409,409L,410S,420,430,201,202,etc.

Thickness of stainless steel:

From 0.3mm to 100mm

Width of stainless steel:

1000mm,1219mm,1250mm,1500mm,1800mm,2200mm,2500mm or as your requirement

Length of stainless steel:

2000mm,2438mm,2500mm,6000mm,6096mm or as your requirement

Application of stainless steel:

Stainless steel plate applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Our company has cooperative relation between the domestic agents. Stainless steel plate can be made accordingto the customers requirements. Fasten delivery. Quality assured.Welcome to order more.

Contacts

If you have any question,please feel free to contact us.

- Q: What is the general width range of stainless steel sheet? What are the common widths?

- According to the agreement can be scheduled to open, usually to add money, commonly used thin 3mm below the general specifications commonly used, 1000*20001219*2438, 3mm or more commonly used specifications 1500*6000.

- Q: Are stainless steel sheets suitable for desalination plants?

- Indeed, desalination plants find stainless steel sheets to be quite appropriate. Stainless steel exhibits remarkable resistance against corrosion and can endure the severe circumstances encountered in such plants, such as contact with saltwater and exposure to high temperatures. Its exceptional durability and mechanical characteristics render it an ideal material for multiple components in desalination plants, such as piping, heat exchangers, and tanks. Furthermore, stainless steel possesses commendable hygiene properties, rendering it suitable for desalination plants that necessitate stringent cleanliness standards. Moreover, the fabrication and installation of stainless steel sheets are effortless, allowing for efficient construction and maintenance procedures in desalination plants.

- Q: How high is the temperature of 2520 stainless steel?

- 310S stainless steel austenitic chromium nickel stainless steel has good oxidation resistance, corrosion resistance, because the higher percentage of chromium and nickel, which has much better creep strength, can continuously work under high temperature, good heat resistance, softening temperature is more than 800[1], and the allowable stress continued to decrease, the highest use temperature of 1200 DEG C.

- Q: Can stainless steel sheets be used for insulation?

- No, stainless steel sheets cannot be used for insulation. Stainless steel is a good conductor of heat and electricity, so it would not provide adequate insulation.

- Q: How do you bend stainless steel sheets?

- To effectively bend stainless steel sheets, a combination of skill, knowledge, and the right tools is necessary. Follow these steps for successful bending: 1. Identify the specific grade of stainless steel you are working with as each grade possesses unique characteristics affecting malleability and bending response. 2. Prior to bending, ensure the stainless steel sheet is clean and devoid of any dirt or debris. Use a mild detergent and a soft cloth for surface cleaning. 3. Mark the precise bending line by measuring and indicating the desired spot. Utilize a ruler or straight edge for accuracy. 4. Select an appropriate bending tool based on the size and thickness of the stainless steel sheet. Options include a press brake, rolling machine, or bending machine. 5. Gradually apply pressure by placing the stainless steel sheet in the bending tool, aligning it with the marked bending line. Avoid excessive force to prevent cracking or deformation. 6. Adjust the bending angle as needed by repositioning the stainless steel sheet within the bending tool. Utilize the tool's adjustments or supplementary tools like clamps for precise angles. 7. Inspect the result by carefully removing the stainless steel sheet from the bending tool. Check for defects, cracks, or unevenness. Minor adjustments can be made using a rubber mallet or a hammer with a soft face. Keep in mind that bending stainless steel sheets requires practice and precision. Begin with smaller projects and gradually advance to more complex bends. If uncertain or lacking experience, consult a professional in metal fabrication for the best outcomes.

- Q: Are stainless steel sheets suitable for architectural mesh or screens?

- Yes, stainless steel sheets are indeed suitable for architectural mesh or screens. Stainless steel is a versatile and durable material that offers numerous advantages for architectural applications. It is resistant to corrosion, which is crucial for outdoor installations or areas with high humidity. This resistance ensures that the mesh or screens will maintain their structural integrity and aesthetic appeal over time. Additionally, stainless steel has a high strength-to-weight ratio, making it an ideal choice for architectural mesh or screens that require both durability and flexibility. It can be easily fabricated into different shapes and sizes, allowing for custom designs and variations. Stainless steel also offers a sleek and modern appearance, which enhances the overall aesthetic of architectural projects. Overall, stainless steel sheets are a reliable and suitable material for architectural mesh or screens due to their corrosion resistance, strength, versatility, and aesthetic appeal.

- Q: What are the benefits of using brushed stainless steel sheets in hospitality design?

- Using brushed stainless steel sheets in hospitality design offers several advantages. To begin with, these sheets provide a sleek and modern aesthetic to any space. The brushed finish creates a unique texture and visual appeal, making it a popular choice in contemporary design. It can elevate the overall look and feel of a hospitality establishment, giving it a sophisticated and upscale ambiance. Furthermore, brushed stainless steel sheets are highly durable and long-lasting. They are resistant to corrosion, scratches, and stains, which is crucial in high-traffic environments like hotels and restaurants where there is constant use and potential for spills. These sheets can withstand the wear and tear of daily use, ensuring they maintain their pristine appearance for years. Moreover, brushed stainless steel sheets are easy to clean and maintain. Being non-porous, they do not absorb liquids or odors, making them hygienic and suitable for use in hospitality settings where cleanliness is of utmost importance. A simple wipe down with a mild detergent is usually sufficient to remove any dirt or smudges, making it a practical choice for busy establishments. Additionally, brushed stainless steel sheets offer versatility in terms of finishes and colors, allowing for creative customization. This versatility enables designers to incorporate them into various design schemes, whether it be minimalist, industrial, or even a more traditional look. The ability to choose from different textures and shades ensures that brushed stainless steel sheets can seamlessly integrate with the overall design concept of a hospitality space. Lastly, brushed stainless steel sheets are environmentally friendly as stainless steel is fully recyclable. By opting for this material, hospitality establishments can contribute to reducing waste and minimizing their environmental footprint. Overall, the advantages of using brushed stainless steel sheets in hospitality design are numerous. From their aesthetic appeal and durability to their ease of maintenance and environmental sustainability, this material is an excellent choice for creating a stylish and functional space in the hospitality industry.

- Q: Are stainless steel sheets resistant to nitric acid?

- Yes, stainless steel sheets are generally resistant to nitric acid due to the presence of chromium in their composition, which forms a passive oxide layer protecting the material from corrosion caused by nitric acid.

- Q: What is the difference between cold rolled and hot rolled stainless steel sheets?

- The main difference between cold rolled and hot rolled stainless steel sheets lies in the manufacturing process. Cold rolled stainless steel sheets are produced by rolling the steel at a lower temperature, which results in a smoother and more polished finish. Hot rolled stainless steel sheets, on the other hand, are produced by rolling the steel at a higher temperature, which makes them less smooth and less polished. Additionally, hot rolled sheets tend to have a thicker gauge compared to cold rolled sheets.

- Q: How do you determine the best thickness of stainless steel sheet for a specific application?

- Several factors need to be taken into account when determining the optimal thickness of a stainless steel sheet for a specific application. First and foremost, the intended use of the stainless steel sheet is of utmost importance. Different applications necessitate varying levels of strength, durability, and resistance to corrosion. For instance, if the sheet will be employed in a high-stress environment or exposed to harsh chemicals, it would be prudent to opt for a thicker gauge stainless steel sheet in order to ensure sufficient strength and corrosion resistance. In addition, the size and dimensions of the application must be considered. Larger structures or components may necessitate thicker stainless steel sheets to maintain structural integrity and prevent deformation under load. Conversely, smaller or more delicate applications may benefit from thinner sheets to reduce weight and enhance flexibility. Furthermore, it is crucial to take into account the expected lifespan and maintenance requirements. Generally, thicker stainless steel sheets offer greater longevity and can withstand more wear and tear. However, if the application calls for frequent cleaning or maintenance, a thinner sheet may be more practical. Budgetary constraints should also be factored in. Thicker stainless steel sheets tend to be more costly due to the increased material expense and manufacturing complexity. Striking a balance between desired performance and available resources is crucial in determining the most cost-effective thickness. Lastly, seeking insights from industry standards, guidelines, and experts can be invaluable. Different industries have specific requirements for stainless steel sheet thickness based on their experiences and safety standards. Engaging with professionals can help ensure that the chosen thickness meets the necessary specifications and regulations. In conclusion, the determination of the optimal thickness of stainless steel sheet for a specific application involves considering the intended use, size, expected lifespan, maintenance requirements, budget, and seeking expert guidance. By carefully evaluating these factors, one can make an informed decision and select the most suitable thickness for their specific needs.

Send your message to us

Stainless Steel Sheet and Plate with Polishing Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords