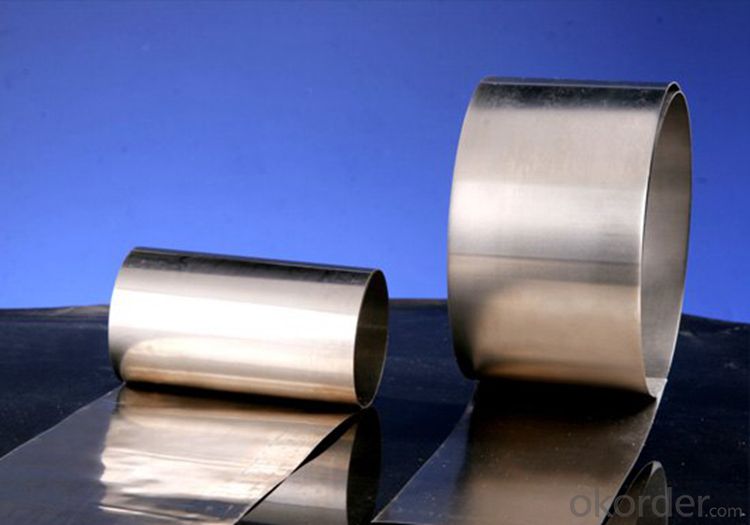

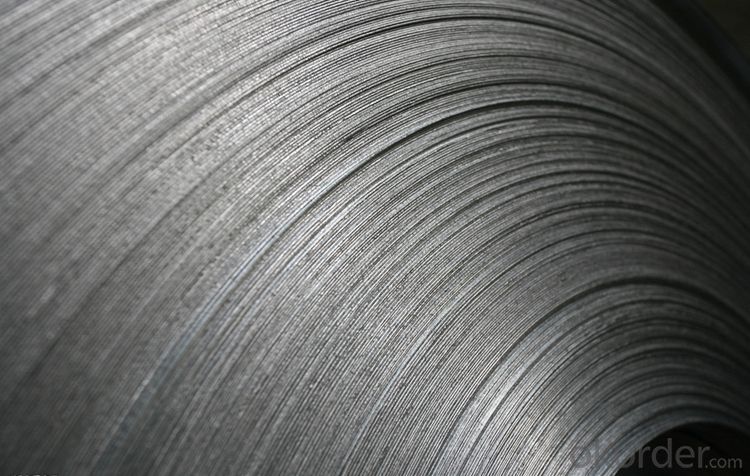

Cold Rolled Stainless Steel sheets,Stainless Steel Coils, Grade 304, NO.2B Finish made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What are the different types of stainless steel sheet finishes for decorative purposes?

- There are several different types of stainless steel sheet finishes that are commonly used for decorative purposes. These finishes are achieved by various surface treatments and processes, each resulting in a unique appearance and texture. Some of the most popular finishes include: 1. No. 4 finish: Also known as brushed or satin finish, it is achieved by applying a series of abrasive belts to the surface, resulting in a smooth, satin-like appearance. This finish is commonly used in architectural and decorative applications. 2. No. 8 mirror finish: This finish is achieved by polishing the surface to a highly reflective mirror-like appearance. It is often used in applications where aesthetic appeal is important, such as wall cladding, signage, and decorative elements. 3. Hairline finish: This finish features a fine, directional grain pattern created by polishing the surface with fine abrasive belts. It provides a subtle and elegant look, commonly used in interior design applications like elevators, appliances, and furniture. 4. Embossed finish: In this finish, the stainless steel sheet is pressed with a pattern or texture, creating a three-dimensional surface. This finish is often used in architectural applications, such as wall panels, ceiling tiles, and decorative trim. 5. Bead blasted finish: This finish is achieved by blasting the surface with fine glass beads under high pressure, resulting in a uniform, matte appearance. It provides a unique texture and is commonly used in applications where a non-reflective surface is desired, such as countertops, kitchen appliances, and signage. 6. Colored finishes: Stainless steel sheets can also be coated with various colors through processes like PVD (Physical Vapor Deposition) or powder coating. These finishes provide a wide range of color options, allowing for more design flexibility in decorative applications. Overall, the choice of stainless steel sheet finish for decorative purposes depends on the desired aesthetic, functionality, and application requirements. Each finish offers its own unique look and feel, allowing for versatile design possibilities in various industries.

- Q: What are the different types of stainless steel sheet finishes for food processing applications?

- There are several types of stainless steel sheet finishes commonly used in food processing applications. These include mill finishes, which are smooth and unpolished; 2B finishes, which are slightly reflective and have a smooth, matte appearance; and mirror finishes, which have a highly reflective surface. Additionally, there are also brushed finishes, which have a textured appearance, and embossed finishes, which feature raised patterns or designs on the surface.

- Q: Can stainless steel sheets be used in construction projects?

- Indeed, construction projects can make use of stainless steel sheets. Stainless steel, a versatile and sturdy material, finds widespread application in various construction scenarios. Its reputation for corrosion resistance renders it suitable for outdoor and high-moisture settings. Buildings often employ stainless steel sheets for roofing, wall cladding, structural elements, and decorative aspects. Moreover, they serve interior purposes like countertops, backsplashes, and elevator panels. Furthermore, stainless steel sheets come in diverse finishes and textures, enabling customization and enhancing aesthetic charm in construction endeavors.

- Q: Can stainless steel sheets be used for chemical storage tanks?

- Yes, stainless steel sheets can be used for chemical storage tanks. Stainless steel is known for its corrosion resistance, making it an ideal choice for storing a wide range of chemicals. It is durable, easy to clean, and can withstand high temperatures and pressure, making it a reliable material for chemical storage applications.

- Q: What is the formability of stainless steel sheets?

- The formability of stainless steel sheets is generally good, as they can be easily shaped, bent, and formed into various complex shapes without cracking or breaking.

- Q: Can stainless steel sheets be used for facade cladding?

- Yes, stainless steel sheets can be used for facade cladding. Stainless steel is a durable and corrosion-resistant material, making it suitable for exterior applications such as facade cladding. It provides a sleek and modern aesthetic while also offering protection against harsh weather conditions.

- Q: What's the difference between stainless steel coil and stainless steel plate?

- One is a coil and the other is a strip.

- Q: Can stainless steel sheets be used for aerospace fasteners?

- Yes, stainless steel sheets can be used for aerospace fasteners. Stainless steel is a commonly used material in aerospace applications due to its high strength, corrosion resistance, and ability to withstand extreme temperatures. It is often used for fasteners such as screws, bolts, and nuts in aerospace engineering.

- Q: What are the different shapes available for stainless steel sheets?

- Stainless steel sheets are available in various shapes, including flat sheets, perforated sheets, corrugated sheets, embossed sheets, and diamond plates. These shapes cater to different applications and aesthetic preferences in industries such as construction, automotive, and interior design.

- Q: How do you prevent crevice corrosion on stainless steel sheets?

- To prevent crevice corrosion on stainless steel sheets, it is important to ensure proper cleaning and maintenance. Regularly inspect the sheets for any signs of damage or corrosion and promptly address any issues. Avoid leaving stagnant water or debris in crevices or gaps as they can promote corrosion. Applying protective coatings, such as paints or sealants, can also help prevent crevice corrosion. Additionally, using stainless steel grades that are more resistant to crevice corrosion, such as 316 or 317, can be beneficial in preventing this type of corrosion.

Send your message to us

Cold Rolled Stainless Steel sheets,Stainless Steel Coils, Grade 304, NO.2B Finish made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords