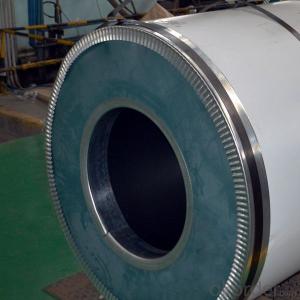

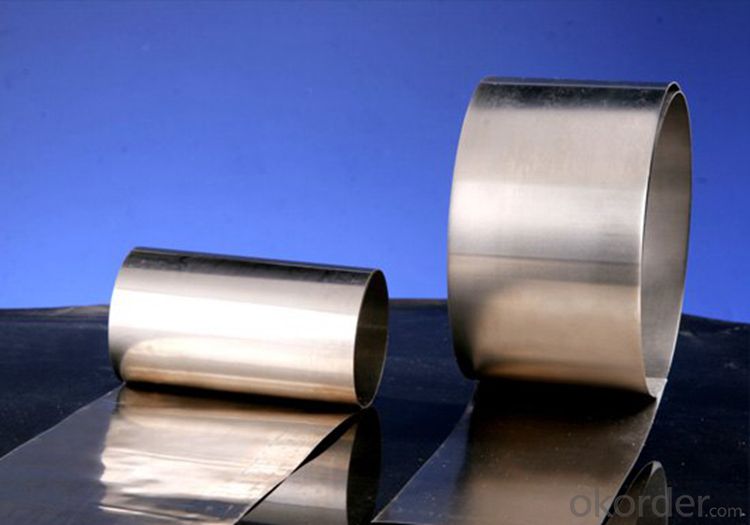

Cold Rolled Stainless Steel Coils 304L NO.2B Finish from China Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for decorative elevator doors or panels?

- Yes, stainless steel sheets can be used for decorative elevator doors or panels. Stainless steel is a versatile material that offers a polished and modern appearance, making it a popular choice for decorative applications. It is known for its durability, resistance to corrosion, and easy maintenance, making it suitable for high-traffic areas like elevator doors and panels. Additionally, stainless steel sheets can be customized with various finishes, patterns, and textures, allowing for endless design possibilities. Whether it's a sleek and minimalist look or a more intricate and decorative design, stainless steel sheets can enhance the aesthetics of elevator doors and panels while providing long-lasting functionality.

- Q: Are stainless steel sheets suitable for industrial applications?

- Yes, stainless steel sheets are highly suitable for industrial applications. Stainless steel is a versatile and durable material that offers several key advantages for industrial use. Firstly, stainless steel is corrosion-resistant, making it ideal for industries that involve exposure to moisture, chemicals, or corrosive substances. It can withstand extreme temperatures, both high and low, without losing its strength or structural integrity. Stainless steel is also highly hygienic, making it suitable for industries such as food processing, pharmaceuticals, and medical equipment. Additionally, stainless steel sheets are known for their excellent strength-to-weight ratio, making them ideal for structural applications in industries such as construction, automotive, and aerospace. They can be easily formed, welded, and fabricated to meet specific requirements. Overall, stainless steel sheets offer a combination of strength, durability, corrosion resistance, and versatility, making them highly suitable for a wide range of industrial applications.

- Q: What is the composition of stainless steel sheets?

- Stainless steel sheets are primarily composed of iron, chromium, and nickel, with varying levels of carbon and other elements depending on the specific grade or alloy.

- Q: Can stainless steel sheets be used for elevator flooring?

- Yes, stainless steel sheets can be used for elevator flooring. Stainless steel is a durable and corrosion-resistant material, making it suitable for high-traffic areas like elevator floors. Additionally, it provides a sleek and modern appearance, making it a popular choice for elevator interiors.

- Q: 304 stainless steel has several advantages, a few big advantages, the more concrete the better

- 304 stainless steel is a universal stainless steel material, antirust performance than the 200 series of stainless steel material stronger. High temperature resistance is also good, the general use of temperature limit is less than 650 degrees centigrade.

- Q: Can stainless steel sheets be used for HVAC systems?

- Yes, stainless steel sheets can be used for HVAC systems. Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it an ideal material for HVAC components such as ductwork, heat exchangers, and exhaust systems. It is also durable and easy to clean, ensuring long-lasting performance in HVAC applications.

- Q: Can stainless steel sheets be used in food processing?

- Yes, stainless steel sheets can be used in food processing. Stainless steel is a common material used in the food industry due to its many beneficial properties. It is highly resistant to corrosion, which is crucial in food processing environments where frequent contact with water, chemicals, and food is expected. Stainless steel sheets are also non-reactive, meaning they do not interact with food or affect its taste, making it a safe choice for food processing equipment. Additionally, stainless steel is easy to clean and maintain, making it suitable for maintaining high levels of hygiene required in food processing facilities. Its durability and strength also ensure that it can withstand the rigorous demands of food processing operations. Overall, stainless steel sheets are a preferred material in the food industry due to their suitability for food processing applications.

- Q: What is the maximum length available for stainless steel sheets?

- The maximum length available for stainless steel sheets can vary depending on the manufacturer and supplier. However, it is common for stainless steel sheets to be available in lengths of up to 120 inches or 10 feet.

- Q: How do stainless steel sheets compare to other materials?

- Stainless steel sheets have several advantages over other materials, making them a popular choice in various industries. Firstly, stainless steel is known for its exceptional durability and strength. It can withstand high temperatures, pressure, and corrosion, making it suitable for a wide range of applications. This durability ensures a longer lifespan and reduces the need for frequent replacements, saving both time and money. Secondly, stainless steel sheets have excellent resistance to corrosion and rust. This property is particularly important in environments with high humidity or exposure to chemicals, as it prevents degradation and maintains the integrity of the material. Other materials, such as aluminum or carbon steel, may require protective coatings or regular maintenance to achieve similar levels of corrosion resistance. Furthermore, stainless steel sheets have a clean and smooth surface finish, making them aesthetically pleasing and easy to clean. This quality is crucial in industries such as food processing, pharmaceuticals, and healthcare, where hygiene and cleanliness are paramount. Stainless steel sheets also offer versatility in terms of fabrication and customization. They can be easily formed, welded, and shaped into different sizes and configurations, allowing for a wide range of applications. This versatility makes stainless steel sheets suitable for architectural, automotive, and industrial uses. Lastly, stainless steel is environmentally friendly. It is 100% recyclable, meaning that it can be melted down and reused without any loss in quality or performance. This recyclability reduces the demand for new materials and lessens the environmental impact associated with manufacturing processes. In summary, stainless steel sheets outperform other materials in terms of durability, corrosion resistance, cleanliness, versatility, and environmental sustainability. These qualities make stainless steel sheets a superior choice for various industries and applications.

- Q: What is the weight of stainless steel sheets?

- The weight of stainless steel sheets can vary depending on their thickness and dimensions. Generally, stainless steel sheets weigh between 1.5 to 3 pounds per square foot.

Send your message to us

Cold Rolled Stainless Steel Coils 304L NO.2B Finish from China Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords