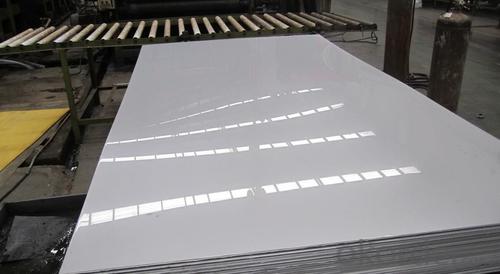

Stainless Steel sheet with best polishing treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

What's the quality?

very fine

How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for storage containers?

- Yes, stainless steel sheets can be used for storage containers. Stainless steel is a durable and corrosion-resistant material that is commonly used in various industries, including food and beverage, pharmaceuticals, and chemical storage. Its ability to withstand high temperatures, resist rust and stains, and its non-reactive nature make it an ideal material for storage containers. Stainless steel sheets can be fabricated into containers of various sizes and shapes, providing a secure and hygienic storage solution for a wide range of products. Additionally, stainless steel is easy to clean and maintain, ensuring the longevity and cleanliness of the storage containers.

- Q: What are the different types of stainless steel sheet perforations available?

- There are several different types of stainless steel sheet perforations available, each with its own unique characteristics and applications. Some of the most common types include: 1. Round hole perforations: These are the most basic and widely used type of perforations. They are simple round holes evenly spaced across the sheet, providing good airflow and visibility. 2. Square hole perforations: Similar to round hole perforations, square holes offer a different aesthetic and can also be used for ventilation or decorative purposes. 3. Slotted perforations: Slotted holes are elongated and provide a larger open area compared to round or square holes. They are often used for drainage or filtering applications. 4. Hexagonal hole perforations: Hexagonal holes offer a unique pattern and are commonly used for architectural or decorative applications. They can also provide good airflow and visibility. 5. Decorative perforations: These types of perforations come in various shapes and designs, including floral, geometric, or abstract patterns. They are typically used for decorative purposes in applications such as building facades or interior design. 6. Micro-perforations: These are very small holes, typically less than 1mm in diameter. Micro-perforated sheets are used in applications where high precision and fine filtration are required, such as speaker grills or air diffusers. It's important to consider the specific requirements of your application when choosing the type of perforation. Factors such as open area, strength, visibility, and aesthetics should all be taken into account to ensure the best perforation choice for your specific needs.

- Q: What's the drill for stainless steel?

- The cutting fluid is made of concentrated emulsions. Commonly used stainless steel drills are: high cobalt bit (M35 bit, M42 bit), in which the M42 bit is the most cost-effective, and carbide drills are also available.

- Q: Are stainless steel sheets resistant to heat and high temperatures?

- Yes, stainless steel sheets are highly resistant to heat and high temperatures. They can withstand extreme temperatures without warping, melting, or losing their structural integrity.

- Q: Can stainless steel sheets be used for countertops or backsplashes?

- Certainly! Countertops and backsplashes can indeed be made from stainless steel sheets. This material is highly durable and can resist stains, heat, and bacteria, which makes it an exceptional option for kitchen surfaces. It is simple to clean, maintains its appearance throughout time, and can endure heavy usage. Not only are stainless steel countertops and backsplashes widely used in commercial kitchens because of their hygienic qualities, but they are also gaining popularity in residential settings due to their stylish and contemporary appearance.

- Q: Are stainless steel sheets available in different patterns?

- Yes, stainless steel sheets are available in different patterns.

- Q: Can stainless steel sheets be used for solar panels?

- Yes, stainless steel sheets can be used for solar panels. Stainless steel is a durable and corrosion-resistant material, making it suitable for outdoor and long-term use. It provides excellent protection against environmental factors such as moisture and UV radiation, which are common in solar panel installations. Additionally, stainless steel has good thermal conductivity, allowing for efficient heat dissipation from the solar cells. This property helps in maximizing the energy conversion efficiency of the panels. Moreover, stainless steel sheets offer a smooth and polished surface, which can enhance the aesthetics of the solar panels. Overall, stainless steel sheets are a viable and popular choice for manufacturing solar panels due to their durability, corrosion resistance, thermal conductivity, and aesthetic appeal.

- Q: Do stainless steel sheets require any special maintenance?

- Stainless steel sheets do not require any special maintenance, but they do need regular cleaning to maintain their appearance and prevent corrosion. Unlike other materials, stainless steel is resistant to staining, rust, and corrosion, making it relatively low-maintenance. However, it is important to clean stainless steel sheets regularly to remove dirt, debris, and fingerprints that can diminish their shine. To clean stainless steel sheets, simply use a soft cloth or sponge with mild soap and warm water, avoiding abrasive cleaners or scrub brushes that can scratch the surface. Additionally, it is recommended to dry the sheets thoroughly after cleaning to prevent water spots or marks. By following these simple cleaning instructions, stainless steel sheets can maintain their beauty and functionality for years to come.

- Q: How do you remove scratches from mirror-finish stainless steel sheets?

- To remove scratches from mirror-finish stainless steel sheets, you can follow these steps: 1. Clean the surface of the stainless steel sheet with a mild detergent and warm water, then dry it thoroughly. 2. Identify the direction of the grain on the stainless steel sheet. The grain usually runs in one direction and appears as faint lines. 3. Using a non-abrasive stainless steel cleaner or a mixture of baking soda and water, gently rub the scratched area along the grain with a soft cloth or sponge. 4. Continue rubbing in a consistent motion until the scratches start to fade. Avoid applying excessive pressure to prevent further damage. 5. Rinse the surface with clean water and wipe it dry with a soft cloth. 6. If the scratches are still visible, you can try using a stainless steel scratch remover or a metal polish specifically designed for stainless steel. Follow the product instructions and apply it to the scratched area following the grain. 7. Once the scratches are no longer visible, clean the surface again with mild detergent and water, then dry it thoroughly to restore the mirror-finish appearance.

- Q: Are stainless steel sheets resistant to staining?

- Yes, stainless steel sheets are highly resistant to staining. This is because stainless steel contains a high percentage of chromium, which forms a protective layer on the surface of the metal. This layer, known as the passive layer, prevents the steel from reacting with oxygen and moisture in the environment, making it resistant to rust and corrosion. Additionally, the smooth and non-porous surface of stainless steel makes it difficult for stains to penetrate and adhere to the material. While stainless steel sheets may still show some signs of staining over time, they can be easily cleaned and restored to their original appearance with minimal effort. Overall, stainless steel sheets are a popular choice for applications where stain resistance is important, such as in kitchens, hospitals, and industrial settings.

Send your message to us

Stainless Steel sheet with best polishing treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords