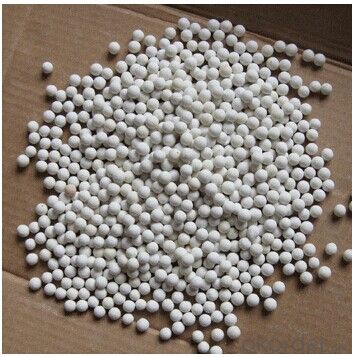

Bio Ceramic Ball Monolithic Refractories for Water Treatment in Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Ingredients:

Tourmaline: 30%

Porcelain clay: 20%

High grade clay: 15-20%

Others: 30-35%

Main Features:

Amount of generating negative ions: 400500pc/s.cm3

Radiance of far infrared ray the wavelength is 225μm≥85%

PH of soaking water solution: 7.2-7.6

Insoluble, gradually releasing mineral substance

Instruction For Use:

Should wash with clean water for two times in the first, then can be directly used for treating drinking water. Keep from raining, and avoid moisture. Stored in dry place.

Note:

the highest using temperature is at 950

Description:

One kind of environmental protection and health care ball that is mainly made of the natural nonmetal mineral tourmaline, kaolin and high-grade clay by nanometer combination technology, special formula and agglomeration techniques, and used with the ceramic ball for activating, purifying and mineralizing drinking water.

Application :

For various types of water purifier, drinking water dispenser and water supply system and equipments, agriculture and industry, etc.

- Q: How do monolithic refractories contribute to reducing emissions in iron and steel processes?

- Monolithic refractories play a crucial role in reducing emissions in iron and steel processes by providing superior insulation, increased energy efficiency, and improved control over the production process. These refractories are designed to withstand extreme temperatures and harsh conditions, effectively minimizing heat loss and reducing the need for excessive fuel consumption. By creating a highly insulated environment, monolithic refractories enable better temperature control, leading to optimized combustion and reduced emissions of greenhouse gases. Additionally, their high resistance to wear and corrosion helps prevent the formation of pollutants, thereby contributing to a cleaner and more sustainable iron and steel industry.

- Q: How are monolithic refractories used in the repair and maintenance of ladles and tundishes?

- Monolithic refractories are used in the repair and maintenance of ladles and tundishes by providing a durable and heat-resistant lining. These refractories can be easily shaped and applied, allowing for quick repairs and preventing heat loss or leakage. They also offer excellent resistance to thermal shocks and chemical corrosion, ensuring a longer lifespan for ladles and tundishes. Monolithic refractories play a crucial role in maintaining the structural integrity and temperature control of these vessels, ultimately improving their overall performance and efficiency.

- Q: What are the key properties of monolithic refractories?

- Monolithic refractories are a type of refractory material that are unshaped or shapeless, meaning they do not have a definite form like bricks or tiles. Instead, they are typically composed of a mixture of aggregates, binders, and additives that can be easily molded and installed in various industrial applications. The key properties of monolithic refractories are: 1. High temperature resistance: Monolithic refractories are designed to withstand extremely high temperatures, making them suitable for applications in industries such as steel, cement, glass, and petrochemicals. They can maintain their strength and structural integrity even at temperatures exceeding 3000 degrees Fahrenheit. 2. Thermal shock resistance: Monolithic refractories have the ability to resist thermal shock, which is the sudden change in temperature that can cause cracking or damage to the refractory. This property is essential in environments where rapid heating or cooling occurs, such as in furnaces or kilns. 3. Chemical resistance: Monolithic refractories exhibit excellent resistance to chemical attack and corrosion from molten metals, slag, gases, and other harsh substances. This makes them ideal for use in environments where they come into contact with acidic or alkaline materials. 4. Low porosity: Monolithic refractories have low porosity, which means they have a high density and are less permeable to gases and liquids. This property helps to prevent the penetration of molten metals or corrosive substances into the refractory, ensuring its longevity and performance. 5. Easy installation and repair: Unlike traditional refractory materials like bricks, monolithic refractories can be easily molded and installed in various shapes and sizes. They can be applied by spraying, casting, or ramming techniques, allowing for faster installation and reduced downtime. Additionally, they can be easily repaired or patched if any damage occurs. 6. Good mechanical strength: Monolithic refractories possess adequate mechanical strength to withstand the stresses and pressures encountered during their service life. This ensures their structural integrity, even under high load conditions. Overall, the key properties of monolithic refractories make them a versatile and reliable choice for a wide range of industrial applications where high temperature resistance, chemical resistance, and thermal shock resistance are required.

- Q: What are the factors affecting the thermal expansion of monolithic refractories?

- There are several factors that influence the thermal expansion of monolithic refractories. 1. Chemical Composition: The chemical composition of the refractory material plays a significant role in its thermal expansion. Different chemical elements and compounds have different coefficients of thermal expansion. For example, materials containing high levels of silica tend to have lower coefficients of thermal expansion compared to materials with higher concentrations of alumina. 2. Particle Size: The particle size distribution of the refractory material can affect its thermal expansion. Smaller particle sizes tend to result in higher thermal expansion due to increased surface area and greater contact between particles. 3. Temperature: The temperature at which the monolithic refractory is exposed can greatly impact its thermal expansion. As the temperature increases, the kinetic energy of the particles increases, causing them to move more vigorously and expand. Different refractory materials have different temperature ranges at which they exhibit significant expansion. 4. Thermal History: The thermal history of the refractory material, including its heating and cooling cycles, can influence its thermal expansion behavior. Repeated heating and cooling cycles can induce microstructural changes in the material, affecting its thermal expansion properties. 5. Porosity: The porosity of the monolithic refractory can affect its thermal expansion. Higher porosity generally leads to higher thermal expansion due to the presence of voids and gaps within the material. 6. Binder Content: Monolithic refractories often contain binders that hold the particles together. The type and amount of binder used can impact the thermal expansion of the refractory. Different binders have different coefficients of thermal expansion, which can influence the overall expansion behavior of the material. 7. Thermal Shock: Rapid temperature changes, such as during quenching or exposure to alternating heating and cooling, can cause thermal shock in the refractory material. This can lead to cracks, spalling, and changes in the thermal expansion behavior. Understanding these factors is crucial in selecting the appropriate monolithic refractory material for specific applications, as the thermal expansion characteristics can directly impact the performance and longevity of the refractory in high-temperature environments.

- Q: Can monolithic refractories be used for the lining of ladle refining furnaces and VOD converters?

- Yes, monolithic refractories can be used for the lining of ladle refining furnaces and VOD (Vacuum Oxygen Decarburization) converters. Monolithic refractories are versatile materials that can be shaped and installed in various applications, including high-temperature environments like ladle refining furnaces and VOD converters. Monolithic refractories are composed of a single, homogeneous material, which makes them easy to install and repair. They can be either cast or gunned in place, providing flexibility in lining design and installation. The lining of ladle refining furnaces and VOD converters requires materials that can withstand high temperatures, chemical reactions, and mechanical stresses. Monolithic refractories, with their excellent thermal shock resistance and resistance to chemical attack, are well-suited for these demanding applications. In ladle refining furnaces, monolithic refractories are used to line the ladle, which holds and processes molten metal. These refractories help maintain the desired temperature and protect the ladle from the corrosive effects of molten metal and slag. They also provide insulation to minimize heat loss and improve energy efficiency. VOD converters are used in the steelmaking process to reduce the carbon content of molten steel. Monolithic refractories are used to line the converter's vessel and maintain the necessary temperature for the decarburization reaction. They also provide protection against the corrosive effects of molten metal and slag, ensuring the longevity and performance of the converter. Overall, monolithic refractories offer excellent properties for the lining of ladle refining furnaces and VOD converters. Their versatility, ease of installation, and resistance to high temperatures and chemical attack make them an ideal choice for these critical applications in the steel industry.

- Q: Can monolithic refractories be used for the lining of reheating furnaces and walking beam furnaces?

- Yes, monolithic refractories can be used for the lining of reheating furnaces and walking beam furnaces. Monolithic refractories are versatile and can be shaped to fit the specific requirements of these furnaces. They offer excellent thermal insulation, high temperature resistance, and durability, making them suitable for withstanding the extreme conditions within these furnaces. Additionally, monolithic refractories can be easily installed, repaired, and replaced, making them a practical choice for lining these types of furnaces.

- Q: How do monolithic refractories resist corrosion and erosion in the iron and steel industry?

- To combat corrosion and erosion in the iron and steel industry, monolithic refractories are designed with a combination of composition and application techniques. Firstly, the composition includes high-quality raw materials like alumina, magnesia, and silica, which possess exceptional resistance to corrosion and erosion. For example, alumina can withstand high temperatures and chemical attacks, making it an ideal choice for protecting against the corrosive nature of the industry. Additionally, the application techniques used in installing monolithic refractories are crucial for their resistance. These techniques, such as gunning, ramming, or casting, ensure a tight and seamless bond between the refractory and the steel structure, reducing the chances of corrosion and erosion. Furthermore, monolithic refractories can be tailored to meet the specific needs of different parts of the iron and steel industry. For areas exposed to molten metal, refractories with high thermal conductivity and resistance to chemical attack are utilized. This customization enhances the refractory's effectiveness in resisting corrosion and erosion. Moreover, monolithic refractories often incorporate additives or binders to further enhance their resistance. These additives provide extra protection against chemical attacks from molten metal or corrosive gases, making the refractory even more durable in harsh conditions. In summary, monolithic refractories effectively resist corrosion and erosion in the iron and steel industry due to their composition, application techniques, customization, and the inclusion of additives. By combining these factors, these refractories ensure the longevity and efficiency of steel structures in the challenging environments of the industry.

- Q: What are the common applications of monolithic refractories in blast furnaces?

- Monolithic refractories, also referred to as unshaped refractories, find extensive use in blast furnaces due to their advantageous properties and versatile applications. Blast furnaces benefit from the following common applications of monolithic refractories: 1. Furnace lining: The walls, hearth, and roof of blast furnaces are lined with monolithic refractories. These refractories possess high thermal resistance and excellent insulating properties, safeguarding the furnace structure against extreme temperatures and thermal shocks. 2. Repair of tuyeres and tapholes: Tuyeres are nozzles that introduce air or fuel into the furnace, while tapholes are openings used for tapping molten iron or slag. Monolithic refractories are employed to repair and maintain these crucial components, as they can endure the high temperatures and chemical reactions taking place in these regions. 3. Hot repair and maintenance: The demanding operating conditions of blast furnaces necessitate frequent repairs and maintenance. Monolithic refractories are utilized for hot repair and maintenance purposes, as they can be easily applied in a plastic or semi-plastic state to fill cracks, mend damaged areas, or replace worn-out linings. 4. Resistance to erosion and corrosion: Blast furnace environments are highly corrosive due to the presence of molten iron, slag, and other molten materials. Monolithic refractories with exceptional erosion and corrosion resistance protect the furnace lining against chemical attacks, extending its lifespan. 5. Gunning mixes: Gunning mixes are extensively employed in blast furnaces for their ability to be sprayed or gunned onto the refractory lining. These mixes comprise fine refractory aggregates, bonding agents, and additives. They are applied to repair worn-out areas, seal cracks, and provide a protective layer against erosion and slag penetration. 6. Repair of slag line and iron runners: The slag line and iron runners in blast furnaces are prone to erosion and wear due to the corrosive nature of molten slag and iron. Monolithic refractories are utilized to repair and reconstruct these areas, ensuring smooth and efficient furnace operation. To summarize, monolithic refractories play a vital role in blast furnaces, fulfilling numerous functions such as furnace lining, tuyere and taphole repair, hot repair and maintenance, erosion and corrosion resistance, gunning mixes, and repair of slag line and iron runners. Their ability to withstand high temperatures, chemical attacks, and mechanical stresses renders them indispensable in maintaining the integrity and efficiency of blast furnace operations.

- Q: How do monolithic refractories contribute to energy efficiency in iron and steel manufacturing?

- Monolithic refractories contribute to energy efficiency in iron and steel manufacturing through their superior insulation properties and ability to withstand high temperatures. These refractories minimize heat loss, reducing the energy required for heating and maintaining the desired temperature in the manufacturing process. Additionally, their durability and resistance to thermal shock help to extend the lifespan of furnaces and other equipment, reducing the need for frequent repairs or replacements, further enhancing energy efficiency.

- Q: What are the recommended storage and handling practices for monolithic refractories?

- The recommended storage and handling practices for monolithic refractories include storing them in a dry and covered area to prevent moisture absorption, avoiding direct contact with the ground to prevent contamination, and ensuring proper ventilation to prevent condensation. It is important to handle them with care, avoiding dropping or hitting them, and using appropriate lifting equipment when necessary. Additionally, following the manufacturer's guidelines for installation, curing, and drying processes is crucial to ensure optimal performance and longevity of the monolithic refractories.

Send your message to us

Bio Ceramic Ball Monolithic Refractories for Water Treatment in Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords