API Cast Steel Check Valve Flange RF in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

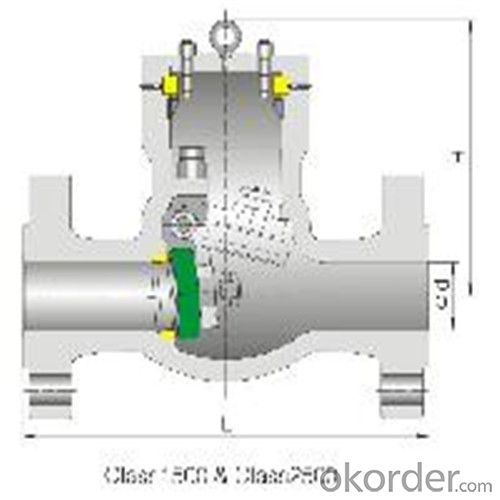

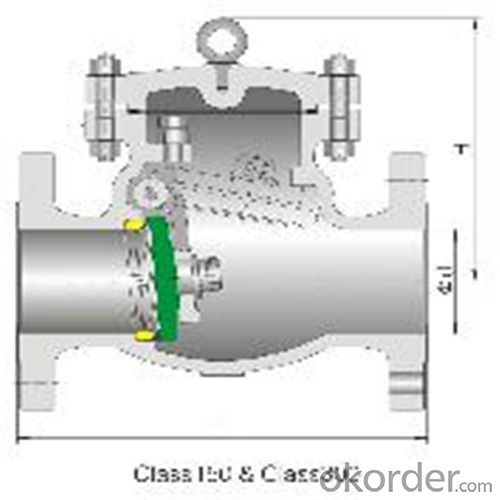

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: How do you clean an EGR valve on a 1999 Ford Taurus DOHC? What do I do and what can I use? Will water work? I've read a lot about a plunger mechanism but I have no idea what this is. Please explain in the best detail you can how to remove, clean, and re install the EGR valve?

- you don,t want to use water. the way i clean mine on my oldsmobile is i take it off and take a rag and some carburator cleaner and clean the bottom off where those little pintals are at. make sure the pintals work back and forth without sticking.

- Q: What are a sing of a bad Idle control valve, will this cause bad mpg?

- No, the valve is there to provide a steady idle regardless whether the transmission is in gear or the air conditioner kicks on. If the Idle Air Control (IAC) valve is not working right the engine will usually idle low and try to stall, although it can also cause high idle.

- Q: I just bought a brand new rain bird sprinkler valve with flow control and when I turn the valve on automatically or manually it makes a loud sound that resembles a muted horn and when I close it, it makes the same sound but thumps at the end. Is this normal? Or do I need to get a new valve?

- Provided you are talking about the valve that controls flow from the constant on of water to the sprinklers, that also cuts it off, the turning on is a groaning of the built up pressure (normal) releasing into the sprinkler line. The thump only occurs at the end when you close it because it's slowly cutting off the pressure. Its more pronounced in the sprinkler valves because you are dealing with greater pressure than say when you turn on a sink or hose, in fact you can nearly mimic a more muffled version of the sound by using a hose, and kinking it or using a nozzle head. Having installed 20+ of these working with my Dad on his rental properties, I can guarantee they are not silent. Unless water is spraying all over the place, I'm 98% positive its a perfectly functioning valve.

- Q: i went to the heart doc today to get the results from an echocardiogram and he told me i had two leakages in one of the valves of my heart. i dont know why, but i didnt even bother to ask him exactly what that meant because he told me it was nothing to worry about. can anyone tell me more about this?

- What okorder /

- Q: Is there a devise to reverse the flow to a cylinder. Not the pump. But a inline flow deverter that would shift the flow from one side of the cylinder to the other at the end of the stroke automatically without a person interjecting.ie it extends fully then the flow reverses retracting it fully. Then the flow reverses, and it extends fully and so on.Preferably, with as little lag as possible during the transition.I want the pump to run constantly(not reversing) and the cylinder to run constantly. Do not worry about the heat generated.Would love something that ran off the main cylinder(like a secondary piston or valve that would opendivert flow at the end of the stroke) through linkage. But, I am open to electronics if need be. Further more want the return to be metered so that the push and pull forces will be the same(metered through a smaller opening to adjust for the rod).Thankyou

- even though this patent claims it will save money by eliminating a servo controller, it would seem to me to be an expensive item in and of itself. Other mechanisms would use linkages and lost motion to control a pilot shuttle valve. This would operate like the valve assemble for steam reciprocating pumps.

- Q: The hot water shutoff valve to the washing machine was dripping. I removed the packing nut and put in new packing over the weekend. Problem is that the packing nut seems to only go back on at an angle no matter what I do...it may have already been that way though. The valve isn't currently dripping, but I'm not liking the way the packing nut only goes on at an angle. Would it be crazy to keep the existing valve if I keep an eye on it and over time it doesn't drip, or is it too risky to keep this valve given that the packing nut is on at a funny angle? (Local plumbers here in Northern NJ all want around $350 if I were to replace both the hot and cold with a watts single handle valve.) Thanks, J.

- An old saying I like is If it ain't broke, don't fix it!. Even though the packing nut appears to be cross-threaded, if there is no leak, I'd leave it alone. Washer connection stop valves seldom get used. They mostly just stay on, unless you have a washing machine breakdown. I'd just peek at it each washday. If it doesn't leak, I'd leave it be.

- Q: My car hesitates on the highway 55 m/h and up after about 20 minutes of highway driving, I unplugged the EGR valve to see if it still hesitates, but the problem went away after disconnected the Egr, so is it for sure that the valve is bad? Just wanted to make sure there's no other component that could be also be bad. I have a toyota avalon 1997.

- This does not sound like an EGR valve problem. As stated previously, failed EGR valve symptoms tend to occur at an idle. Your problem may be in the passages that feed the inert EGR gasses to the engine. On many engines, there are multiple passages feeding the engine. One for each cylinder. Since EGR flow consists of burned fuel and oxygen, it is an inert gas. Not capable of supporting combustion because there is no oxygen or fuel left in it. It simply takes up space and is used to cool your exhaust output for emissions reduction. If several of these passages plug up, then the remaining cylinders are fed too much of this inert gas and it affects combustion in those cylinders. Normally during highway cruising this inert gas can be fed to all cylinders equally without a noticeable effect on performance. This scenario is possible on any engine that uses EGR ports in the heads or intake manifold to feed individual cylinders. Removing the EGR flow removes the imbalance and your symptom goes away. Barring that, it is still unlikely that the valve is the cause of your symptom. EGR flow at the wrong time such as during acceleration but not at idle can be caused by the vac controls. Hope this helps!

- Q: for a big block chevy,best way to adjust valves and rockers

- The running method is a good way to set the valves but you can set them with the engine not running to turn the motor to top dead center the rockers that have got the valves closed you loosen the rocker and spin the push rod kept spinning the push rod and tighten the rocker till you fell a slight resistance on the push rod or it do's not spin freely turn motor over 180 and do the rest this is setting every thing at 0 lash and you will not blow oil all over your engine bay they do make rocker oil stoppers but not had any luck with them. a lot of time ween you set the valves with the motor running and if not done it before you will set them to tight but ether method is a good one. good luck

- Q: are the carborator reed valves supposed to be open or closed on a 1999 yz 250?dirt bike

- reed valves depend on engine vacuum to operate. the reed valves are closed when the engine is off and as the engine load goes up, it requires more fuel so engine vacuum goes up causing the reed valves to open more, letting in more fuel. So, is the engine running or off?. are the reeds bent? if they are, they might be straightened if u use care. they break ez.

- Q: We have a main gas valve outside and there's a gas valve by out air condition and we want to know which way if off and on .. Does anybody know !!!

- Generally speaking the valve has a handle that pivots from parallel, to perpendicular. Open is in line, or parallel. Closed is perpendicular. If it's a rotating handle, then the valve stem will be all the way in when closed, or all the way out when open. The valve stem is located in the center of the wheel that you would turn. Hope that works for you.

Send your message to us

API Cast Steel Check Valve Flange RF in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords