API Cast Steel Check Valve Flange RTJ in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

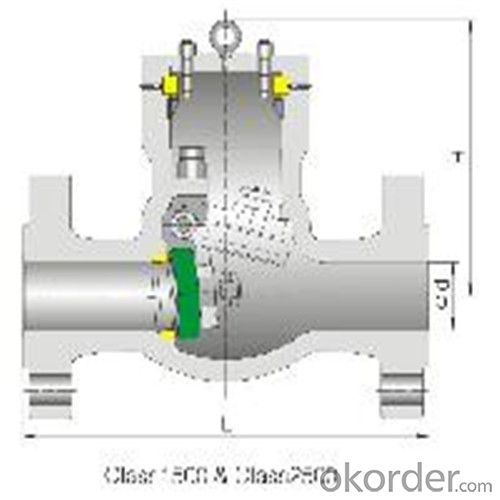

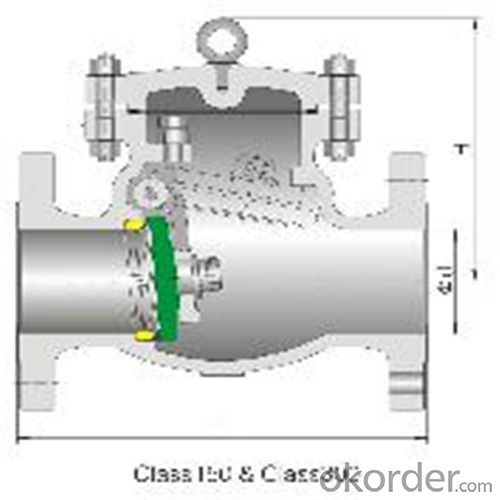

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: After shutting off the hot and cold water lines to my washer to remove the unit from my laundry room i noticed a small leak coming from the hot water valve as if the valve is not completely closing. The valves themselves should be roughly 10 years old and were extremely tight when attempting to close them, my question is how big of a job is this to replace the water valve? Is it as simple as turning off the main water to the house and replacing the valve or are these typically soldered on? Currently i just ran the hose for the hot water to the drain line to prevent water from leaking onto the floor so is this something that is a fairly non issue once i hook the lines back up to the washer and turn them back on? Or is this something i should get addressed asap?

- Of course, the best solution is to replace the valve. Valves are either soldered on or attached to the pipe with compression fittings. If the pipe is copper and you see a silver band of metal between the pipe and the valve, that's probably solder. In this case, it would be best to let a plumber replace the valve. Otherwise, if your valve is attached with a compression fitting, you can get a new valve at your local home improvement store in the plumbing section. I recommend getting a 1/4 turn, steel ball valve. These are very simple and reliable valves. When you remove the old valve, be sure to also remove the compression washer and shoulder nut as well. You'll want to use the new ones that come with your valve. I also recommend using Teflon tape to wrap the threads of your new valve, at least two times in the direction of nut tightening. This will reduce the chance of leakage through the threads. Tighten the compression washer between the valve and the shoulder nut snugly. Make sure the valve is off. Turn the water on and check for leaks. If you see periodic drips, tighten the shoulder nut until the dripping stops. The other cheap and dirty alternative is to get a cap for your existing valve. These are also available in the plumbing section of your home improvement store. They run about $2-3, I believe, and are threaded onto the faucet where your hose attaches. That will keep your leaking valve from dripping all over the place.

- Q: A reading from my 2002 ford explorer said insufficient flow from the EGR valve. Would it be possible to clean the valve or fix it or would I need to buy a whole new valve?

- Could be dirty, or it could be the egr solenoid failing

- Q: I was looking at the specs on my audi a4 and it said 30 valves and I was looking at a few other cars and they said 24 valves. What do the valves determine? Whats the difference if the car has more valves than another?

- Audi now uses 5 valves per cylinder. Why? They obviously believe it offers advantages over conventional 12 or 24 valve systems (for 6 cylinders) but it's not clear what benefits it has to Audi buyers. Is is just more complex and more likely to have problems? Who knows?

- Q: i have a zone that - when turnd on by timer or manually only about 1 foot of spray comes out of sprinkler heads (used to wk fine). When i turn the ittle screw on top of valve (its about the size of a dime) water pressure comes up and wks fine - only water leaks at screw and when zone comes on next time NO pressure??? metal valves were just replaces about 1 yr ago.

- No. that's not gas tight and the plastic factors would possibly no longer delight in the petroleum ecosystem. you will choose a valve it is meant for propane. And the suitable valve would matter on the rigidity the place you meant to place in the valve interior the line. you will additionally would desire to layout the entire element very intently - no open touch relays - to steer away from a spark that would spark off errant propane.

- Q: ok im buying a kx 125 from 96 and he said the only problem with the bike is that it has a small oil leak around the power valve too me it sounds like a gasket. but i want someone elses opinion on what else it could be.

- The kx125 actually has 3 valves in the exhaust, a main, a left-hand one and a right-hand one. Each is fitted with o-rings which require disassembly in order to be reached. This would also be a good time to clean the power valves since they tend to become encrusted with carbon deposits which interfere with their normal operation.

- Q: does it moves up and down with the valve stem??

- A poppet valve is a valve consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve.. not sure if you are talking about tire valve stems? if so the poppet valve moves within the valve stem. I have also heard them referred to as Schrader valves see link

- Q: My third valve is always sticking, despite the fact that I oil them thoroughly every other day. It scrapes the sides of the case when I take it out/put it in, it's almost as if the valve is too big for it. Often times it will stick and I'll have to unscrew it and physically pull it out for it to be functional again.I've inspected it, and the inside looks just like the others which are fine. I've tried washing it, oiling it, and putting a trace amount of vaseline on it. What is the problem?

- Have you tried cleaning the valve casing (what the valve moves in)? If not, you can use a clean cloth that won't leave fibers in there, or a valve casing brush (couple dollars at the music store) to clean the inside. Many times dirt builds up at the bottom of the valve casing where it's supposed to and the valve eventually gets stuck in it. Also, like the poster above said, the plastic/metal guide could be getting caught. You can use slide grease to lubricate the slot in the top part of the valve (not the casing) where the guide moves. Just don't get any on the piston part of the valve. If all else fails, it is possible that the valve was not honed correctly at the factory and a professional will need to fix it.

- Q: I want to put a blow off valve in my car to make it sound cool lol but i dont have a turbo yet ... do i even need one?

- Without a turbocharger there is nothing to blow off. Like asking if you need a lamp to use a light bulb.

- Q: My pressure reducing valve (or restricting valve) was looked at by three master plumbers and they all said I need a new one. My water pressure has been low for weeks. It measures about 100 psi at the outside hose bibs, but it is very low inside and suddenly reduces after you turn on the facets inside. The shower is ok. My automatic sprinkler system is not able to work now due to low pressure. A relative of mine thinks we can just add a handle (as one is missing) on the valve and adjust the pressure ourselves. The repair of the valve is around $500-600! I am told in Texas that we have to have a permit and inspection to repair this valve. Also I was told by the last plumber that came out, that I have to install a expansion tank on my new hot water heater according to code. I'm not sure if that is a city code or federal. Please respond as to information you may have on this problem. The expansion tank is required I'm told when you have a pressure reducing valve for safety, is this true?

- The cost you quoted seems a bit high to me. Mine didn't cost anywhere near that amount in East Texas. A pressure reducing valve acts like a check valve when there is no flow. That is it closes as the pressure rises when you are not using any water. In this condition, the hot water heater can raise the pressure even higher since there is no place for the expanding water to go. That is the reason for the expansion tank. Without the expansion tank the pressure relief valve on the hot water heater can relieve unnecessarily or weep a bit.

- Q: My boyfriend is getting mitral valve replacement surgery soon, he is getting a mechanical valve put in.Has anyone had this surgery done? What are the risks. Anything else need to know about this surgery that is important. Im just worried about the surgery wanting to know as much as I can to be prepared. thank you

- Haven't had it done before but: It's a pretty involved procedure. Patient is put under general anesthesia and is usually on the cardiopulmonary bypass machine (heart-lung machine) since you can't really replace a heart valve if the heart is beating. mortality for full valve replacement according to wiki is 6-8 percent, prob less than 5% for young healthy patients. Recently, many people have been doing the procedure laparoscopically. Patients are put into the surgical ICU for typically 1-2 days after the surgery. You can be discharged about a week after. Obviously there's risks, this is a very involved and definitely not a simple procedure. However, the cardiothoracic surgeons do these procedures every day for their entire lives-they're very skilled and qualified. good luck!

Send your message to us

API Cast Steel Check Valve Flange RTJ in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords