API Cast Steel Check Valve A216 WCB Body Material in Accordance with ISO17292、API 608、BS 5351

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

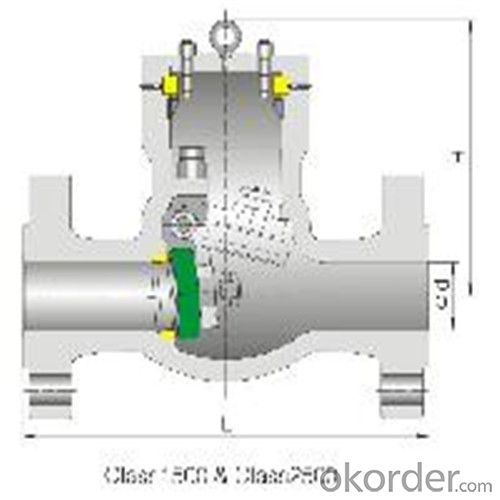

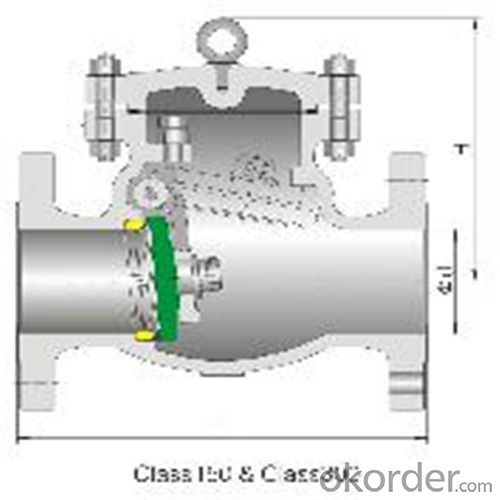

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Im looking for a new BBb tuba. i would like six valves at 4+2. but if not looking for 6 valve BBb tuba

- Better get busy with that search engine, then!

- Q: i was thinkin i needed rings cause my car was smokin like hell and had a bad compression test on one cylinder. anyways i got the head off and my valves are caked with black **** all down one side and the others are completely white. i dont know if when the car turns off if they're supposed to seal but four of them were about a quarter inch off the head. before i tested everything i was smokin like hell and barely runnin and you could hear a knockin sound in the exhaust at the rear of the car. could the head be the problem or still sound like rings??

- have the head checked for level milling it may be warped if it has ever overheated..

- Q: I gotta 89 Crx si. Just wondering if you could put on a blow off valve and it work without it boosted

- Simply put...No...If you mount it on a cold air intake, you will intake air from where you mount it, and most likely throw off your MAFS and make your car run poorly

- Q: I am doing a big project on Valve and it's games. I am currently doing some research on the company and wanted to see if anyone had any interesting facts or information about Valve that may be useful when doing research, thank you. :)

- Valve Corporation Information

- Q: i have a zone that - when turnd on by timer or manually only about 1 foot of spray comes out of sprinkler heads (used to wk fine). When i turn the ittle screw on top of valve (its about the size of a dime) water pressure comes up and wks fine - only water leaks at screw and when zone comes on next time NO pressure??? metal valves were just replaces about 1 yr ago.

- It's hard to say exactly what's wrong without knowing what type of valves you have since different valves have different components. In any case, I'd start by checking that the bleed screw and/or handle (depending on type) and that the flow control screw or handle (again depends on what make/model you have) to make sure they are in good condition and properly set. Be careful when turning these screws or handles don't force them past the normal stopping points. If that all checks out, there may be some dirt or debris stuck in the valve that's not allowing the diaphragm to open all the way.

- Q: I have a 1997 ford aerostar and my mechanic just called me and said that the pop off valve needs to be replaced, but it is attached to the line so the hole line has to be replaced to. I want to try to find the pop off valve to see if I can get it b/c he can't find the replacement part, what I need to know is what it looks like. or where it is on an aerostar, because I have 5 more sitting in the driveway and I can look for it.

- 1. the pop off valve is normally located in the compressor so if it over pressures it will relieve some of the pressure. it's not in a line. #2. if it's a 1997 it doesn't have R12. it has R134. the only valve in the line is the port to check pressures and vacuum and recharge it. it could have one of those valves leaking and most can be taken apart and a new schrader valve installed. hope this helps.

- Q: hi friends i want to know about the calibration technque of foundation fieldbus based control valve by a analog source

- * okorder moreinfo

- Q: if safe, at what age should a woman with mitral valve prolapse be pregnant?

- definite you could nicely be in threat, and in case you get implants you will ought to circulate to surgical treatment each and every 10 years because of the fact the implant can go down or in specific circumstances it could explode so i prefer to advise to no longer do it

- Q: My son was born with bicuspid aortic valve which has developed a leak. He is now on enalipril 2x per day to decrease the afterflow and buy some time before he has to have surgery, but the doctor has discussed our options and we basically have to choose when it comes down to it, whether we go with a valve repair, or valve replacement and if we do replacement we can do mechanical or donated valve or The Ross procedure. And he will probably be under 5 yrs old when this needs done, (he's 2 now) so I would like to keep him off of coumadin (blood thinner) so he can play sports in school if he would like. But I also want to do what is the best for him long term. Any advice would be helpful. thanks

- Wow, okorder /... Good luck to you and your son and I am very sorry you are having to go through this difficult decision.

- Q: I'm going to replace a valve guide and wondering how I should do it.Should I drill into the existing valve guide to the point it's small enough to pinch with some pliers and pull it out?When I put the new one in, should I use a wooden dowel and an air nailer to pound the guide into place?The more info. the better. It's my first time doing this.Thanks!

- Ohhhh man. NO DRILLS. I assume you are referring to an Aluminum Cylinder head. To do it correctly you need a drift punch that has a pilot size of the valve stem, and an outside diameter that is just a few thousands smaller than the guide. Disassemble the head completely, put in Moms oven at the highest setting it will go to ( 5-6 hundred degrees ) Pound old guide out from the combustion camber side. ( have every thing ready to go this FFer will be hot ). Coat new guide with something like STP, put in freezer, carefully align it, then slam it home from the valve train side, don't pussy around, get it in before it attracts the heat of the head, if you stop or it stops you will have to repeat the entire process. If you gall the Aluminum ( say O-**** ) Since you have to hit this thing fairly hard you will need to refinish the inside of the guide with the appropriate reamer. Then refinsh Valve seat ( they never, NEVER line up perfectly )

Send your message to us

API Cast Steel Check Valve A216 WCB Body Material in Accordance with ISO17292、API 608、BS 5351

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords