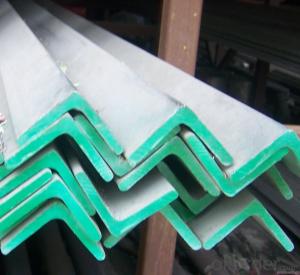

Angle steel for sale with high quality ;

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Are steel angles available in different grades?

- Yes, steel angles are available in different grades. Steel angles are commonly made from carbon steel, which is available in various grades such as A36, A572, and A588. These grades have different chemical compositions and mechanical properties, making them suitable for different applications. Additionally, stainless steel angles are also available in different grades such as 304 and 316, which offer excellent corrosion resistance properties. The choice of steel angle grade depends on the specific requirements of the project, including strength, durability, and corrosion resistance.

- Q: How do you maintain and clean steel angles?

- To maintain and clean steel angles, you can start by removing any dirt or debris using a mild soap and water solution. Avoid using abrasive cleaners or tools that can scratch the surface of the steel. After cleaning, it is important to thoroughly dry the angles to prevent any water spots or rust formation. Applying a protective coating or wax can also help maintain their appearance and prevent corrosion. Regular inspections and prompt removal of any rust spots or stains will ensure the longevity of the steel angles.

- Q: Are steel angles subject to deformation?

- Yes, steel angles are subject to deformation. Steel is a strong and durable material, but it is not immune to the forces that can cause deformation. Deformation can occur in steel angles due to various factors such as excessive loads, bending moments, temperature changes, and improper design or installation. When subjected to these forces, steel angles can experience bending, twisting, or warping, leading to a change in their original shape. To prevent or minimize deformation, engineers and designers can consider factors such as selecting the appropriate steel grade, calculating load capacities, and ensuring proper support and bracing.

- Q: What are the design considerations when using steel angles?

- When incorporating steel angles into design, there are several important factors to keep in mind. Firstly, the load-bearing capacity of the steel angles must be thoroughly evaluated. The anticipated loads and stresses that the structure will endure should dictate the selection of the appropriate size, thickness, and configuration of the angles. Another factor to consider is the structural integrity of the connections between the steel angles and other design elements. The connections must be designed to provide sufficient strength and stiffness, while also accommodating any potential movement or deformation of the angles. The potential for corrosion when using steel angles should also be taken into account. To prevent rust and deterioration, it is essential to apply suitable protective coatings or treatments, especially in outdoor or high-moisture environments. Aesthetics and visual appeal are also significant considerations in design. The shape, finish, and overall appearance of the steel angles should align with the desired aesthetic of the project, whether it is a modern, industrial look or a more traditional and ornamental design. Finally, cost and availability should be considered when incorporating steel angles. The project's overall budget should be weighed against the cost of materials, fabrication, and installation. Additionally, it is important to consider the availability of the desired sizes and configurations of steel angles to ensure a smooth and timely construction process. By carefully considering these design factors, designers can effectively integrate steel angles into their projects, guaranteeing structural integrity, aesthetic appeal, and cost-effectiveness.

- Q: What are the different types of steel angles?

- There are several different types of steel angles, each designed for specific applications and purposes. Some of the common types include: 1. Equal angle: This type of steel angle has equal sides and is widely used in construction for structural support, bracing, and framing. 2. Unequal angle: Also known as L-shaped or unequal leg angle, this type of steel angle has unequal sides, with one longer side and one shorter side. It is commonly used in building construction to create corners, edges, and supports. 3. Stainless steel angle: Made from stainless steel, this type of angle offers excellent corrosion resistance and is commonly used in applications where exposure to moisture or chemicals is a concern, such as in marine environments or food processing facilities. 4. Galvanized angle: Galvanized steel angles are coated with a layer of zinc to provide protection against rust and corrosion. They are commonly used in outdoor and industrial applications where durability is essential. 5. Slotted angle: Slotted steel angles have holes or slots along their length, allowing for easy attachment and adjustment of components. They are commonly used in shelving systems, storage racks, and DIY projects. 6. Rolled steel angle: This type of angle is created by rolling steel into a specific shape, resulting in a uniform and smooth surface. Rolled steel angles are often used in manufacturing, machinery, and structural applications. 7. Structural angle: Structural steel angles are designed to bear heavy loads and provide structural support in construction projects. They are often used in building frames, bridges, and other infrastructure projects. These are just a few examples of the different types of steel angles available. The choice of angle will depend on the specific requirements of the project, including load capacity, corrosion resistance, and aesthetic considerations. Consulting with a professional or structural engineer can help determine the most suitable type of steel angle for a particular application.

- Q: What are the different types of steel angles connections for roof trusses?

- Roof trusses commonly utilize different types of steel angle connections to ensure strong and stable support. These connections are crucial for maintaining the structural integrity of the roof. One frequently employed steel angle connection is the gusset plate connection. This method involves using triangular steel plates to connect the truss members at their intersection points. To establish a secure connection, these plates are typically welded or bolted to the steel angles. Another type of steel angle connection is the angle cleat connection. This approach relies on steel angles to connect the truss members using bolts or welding. These angles are usually bolted or welded to the top and bottom chords of the truss, adding strength and stability. A third option is the angle clip connection, which employs steel clips or brackets to connect the truss members at their intersection points. These clips are typically bolted or welded to the steel angles, creating a robust and secure connection. Lastly, there is the angle bracket connection. This type of connection involves using steel brackets or brackets to connect the truss members. The brackets are typically bolted or welded to the steel angles, providing a reliable and sturdy connection. In summary, various types of steel angle connections can be used for roof trusses, each offering distinct advantages and characteristics. The choice of connection depends on factors such as design requirements, load-bearing capacity, and construction methods.

- Q: Can steel angles be used in the construction of schools?

- Yes, steel angles can be used in the construction of schools. Steel angles are versatile structural elements that can be used to create strong and durable frameworks for various construction projects, including schools. They are commonly used in the construction industry for their high strength-to-weight ratio, which makes them ideal for supporting heavy loads and providing structural stability. Steel angles can be incorporated into the design of school buildings to reinforce walls, support staircases, create open spaces, or serve as structural components for roofs and ceilings.

- Q: Can steel angles be used for roof trusses?

- Yes, steel angles can be used for roof trusses. Steel angles are commonly used in construction for their strength and durability. They can be easily fabricated and installed to create the framework for roof trusses. Steel angles provide excellent support and stability, making them suitable for use in various roofing applications. Additionally, steel angles can withstand heavy loads and adverse weather conditions, making them a reliable choice for roof trusses.

- Q: Can steel angles be used in window frames?

- Yes, steel angles can be used in window frames. Steel angles provide strength and stability, making them suitable for supporting and reinforcing window frames.

- Q: Can steel angles be used in overhead crane or hoist systems?

- Yes, steel angles can be used in overhead crane or hoist systems. They are commonly used as structural components to support and reinforce the various parts of the system, such as the crane bridge, runway beams, and trolley frames. Steel angles provide strength, stability, and durability, making them suitable for withstanding the heavy loads and dynamic forces associated with crane and hoist operations.

Send your message to us

Angle steel for sale with high quality ;

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords