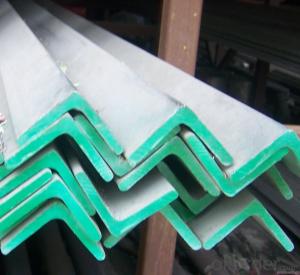

Angle steel with high quality ; Steel angle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: What are the common bending or forming processes used for steel angles?

- There are several common bending or forming processes used for steel angles, depending on the desired shape and specifications. One common process is roll bending, where the steel angle is passed through a series of rollers that gradually bend it into the desired curve or shape. This process is often used for larger angles and provides precise and consistent bending. Another common process is press braking, where the steel angle is placed between a punch and die and a significant amount of force is applied to bend it into the desired shape. This process is versatile and can be used for both small and large angles, allowing for various bending angles and shapes. Hot bending is another method used for steel angles, where the angle is heated to a high temperature and then bent into the desired shape using specialized equipment. This process is suitable for larger angles and allows for more complex bending shapes. Lastly, cold bending is a popular process for steel angles, where the angle is bent using force without the need for heating. This method is commonly used for smaller angles and provides a cost-effective and efficient way to achieve simple bending shapes. Overall, the choice of bending or forming process for steel angles depends on factors such as the size, thickness, and shape requirements, as well as the desired cost and production efficiency.

- Q: How do steel angles contribute to the overall torsional stiffness of a structure?

- There are several ways in which the overall torsional stiffness of a structure can be improved with the use of steel angles. Firstly, the high moment of inertia possessed by steel angles makes them resistant to bending. This resistance to bending aids in the distribution and resistance of torsional forces exerted on the structure, consequently reducing any twisting or warping that might occur. Secondly, steel angles can be strategically positioned and connected within a structure to form bracing or reinforcement systems. These systems serve to transfer and distribute torsional forces throughout the structure, preventing localized areas from undergoing excessive twisting or distortion. In addition, steel angles can be employed to establish rigid connections between different structural components, such as beams or columns. These connections enhance the overall stiffness of the structure by efficiently transmitting torsional forces between the connected components, thereby minimizing any relative movement or deformation. Furthermore, steel angles can also function as diagonal members in truss structures or frames. Through the introduction of diagonals, these angles aid in resisting and distributing torsional forces, thereby upholding the overall stability and rigidity of the structure. Overall, the utilization of steel angles plays a critical role in bolstering the torsional stiffness of a structure. By providing resistance to bending, forming bracing or reinforcement systems, creating rigid connections, and acting as diagonal members, steel angles effectively manage and distribute torsional forces, thus contributing to the overall stability, durability, and performance of the structure.

- Q: What are the different types of connections used for steel angles in steel frames?

- There are several types of connections used for steel angles in steel frames, including welded connections, bolted connections, and riveted connections. Welded connections involve fusing the angles together using heat, creating a strong and permanent bond. Bolted connections involve using bolts and nuts to secure the angles together, allowing for easy disassembly if necessary. Riveted connections involve using rivets, which are metal pins, to hold the angles together by forming a permanent, tight fit. The choice of connection type depends on the specific requirements of the steel frame and the desired level of strength and durability.

- Q: Are steel angles suitable for high-temperature environments?

- Depending on the type of steel used, steel angles can be suitable for high-temperature environments. Excellent heat resistance properties are known for certain stainless steel grades, such as 304 and 316. These stainless steel angles can withstand high temperatures without significant loss of strength or corrosion resistance. They also possess good oxidation resistance, which is crucial in high-temperature environments where oxidation may occur. However, it should be noted that not all steel angles are suitable for high-temperature applications. Carbon steels, for instance, are not recommended for prolonged exposure to high temperatures. They may experience significant structural changes, such as softening or even melting, which can compromise their integrity and strength. When choosing steel angles for high-temperature environments, it is crucial to consider factors such as the specific temperature range, duration of exposure, and the presence of corrosive gases or chemicals. Seeking guidance from a material engineer or a steel supplier with expertise in high-temperature applications can help ensure the selection of the appropriate steel angle with the necessary heat resistance properties for the specific environment.

- Q: What are the different specifications for steel angles?

- The different specifications for steel angles include the dimensions (length, width, and thickness), the weight per foot, the shape of the angle (equal or unequal leg), the type of steel used (such as carbon steel or stainless steel), and any additional features or finishes required (such as galvanized or painted).

- Q: What are the maximum allowable deflections for steel angles?

- The maximum allowable deflections for steel angles depend on various factors such as the type of angle used, the material properties, the loading conditions, and the design codes and standards being followed. In general, the deflection limits are determined to ensure the structural integrity and functionality of the steel angles. Excessive deflections can cause structural instability, reduced load-carrying capacity, and potential failure of the angles. Design codes and standards such as the American Institute of Steel Construction (AISC) specify deflection criteria for different applications. For example, the AISC 360-16 specification provides deflection limits based on the span length and the serviceability requirements of the specific structure. The allowable deflections for steel angles are usually expressed as a fraction of the unsupported span length. Typical deflection limits for steel angles range from 1/240 to 1/360 of the span length, depending on the specific application and loading conditions. It is important to note that these deflection limits are guidelines and should be assessed in conjunction with other design considerations such as strength, stability, and dynamic effects. Additionally, consulting the applicable design codes and standards, as well as seeking professional engineering advice, is crucial to determine the precise maximum allowable deflections for steel angles in a given project.

- Q: Can steel angles be used for temporary structures or scaffolding?

- Certainly, temporary structures or scaffolding can make use of steel angles. Because of their strength and durability, steel angles find frequent employment in construction endeavors. They are regularly employed to furnish structural support and maintain stability in temporary structures and scaffolding arrangements. Steel angles possess versatility, allowing for effortless welding, bolting, or fastening, leading to the creation of robust and secure temporary structures or scaffolding setups. Furthermore, due to the assortment of sizes and thicknesses available, steel angles prove highly suitable for diverse temporary construction applications.

- Q: Are there any industry standards or certifications for steel angles?

- Yes, there are industry standards and certifications for steel angles. The most widely recognized standard for steel angles is the American Society for Testing and Materials (ASTM) standard. The ASTM A36 specification is commonly used for structural steel angles and provides specific requirements for chemical composition, mechanical properties, and dimensional tolerances. In addition to ASTM, other organizations such as the American Institute of Steel Construction (AISC) and the Steel Joist Institute (SJI) provide guidelines and standards for steel angles used in construction and structural engineering applications. These standards ensure that steel angles meet specific requirements for quality, strength, and performance. Furthermore, certifications such as ISO 9001:2015 and ISO 14001:2015 are widely recognized in the steel industry, indicating that a manufacturer has implemented a quality management system and meets environmental management standards. It is important for manufacturers, suppliers, and construction professionals to adhere to these industry standards and certifications to ensure the reliability and safety of steel angles in various applications.

- Q: Can steel angles be used for solar panel mounting?

- Yes, steel angles can be used for solar panel mounting. Steel angles are commonly used in solar panel mounting systems due to their strength, durability, and flexibility. They provide a sturdy and secure structure to support the weight of the solar panels and withstand environmental conditions such as strong winds and heavy snow loads. Steel angles also allow for easy adjustment and positioning of the solar panels to maximize sunlight exposure. Additionally, steel angles can be easily customized and fabricated to meet specific project requirements, making them a popular choice in the solar industry.

- Q: Can steel angles be used in high-temperature environments?

- Steel angles can be used in high-temperature environments, but their performance depends on the specific grade of steel being used. Some steel angles are specifically designed for high-temperature applications and can withstand extreme heat without significant distortion or structural failure. These high-temperature steel angles are typically made from alloys that have excellent heat resistance properties, such as stainless steel or nickel-based alloys. However, it is important to consider the operating temperature and duration of exposure when selecting steel angles for high-temperature environments. Prolonged exposure to high temperatures can still lead to some degradation of the material, including oxidation, reduction in mechanical properties, or even melting in extreme cases. To ensure the suitability of steel angles in high-temperature environments, it is recommended to consult with experts or engineers who have knowledge of the specific application and can provide guidance on selecting the appropriate grade of steel angle. Additionally, regular inspections and maintenance are crucial to identify any signs of degradation or wear caused by high temperatures.

Send your message to us

Angle steel with high quality ; Steel angle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords