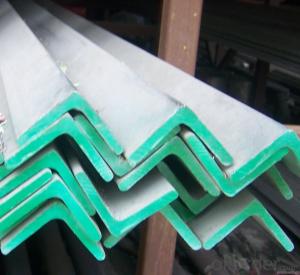

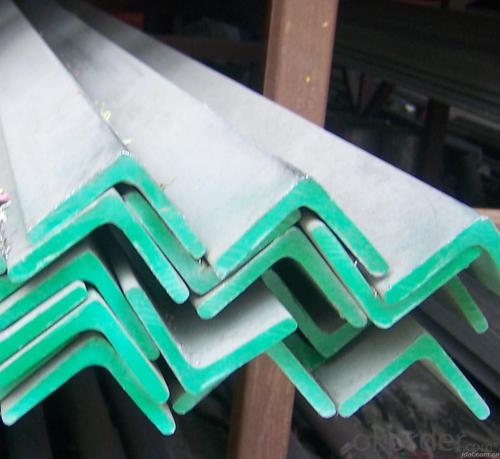

Stainless angle steel; high quality angle steel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless angle steel; high quality angle steelGeneral Informaiton of Stainless angle steel; high quality angle steel

1. Grade: SS200, 300,400 series

2. Size: 25×25×3 mm-100×100×10mm

3. Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package: Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry etc.

Specification of Stainless Steel Angle Bar

Name | Stainless Steel Angles | |||||

Standard | ASTM A554, A312, A249, A269 and A270 | |||||

Material Grade | 304,316,201,202, 316L,430 | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Thickness: +/-0. 15mm | |||||

b) Length: +/-4. 5mm - 0mm | ||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | |||||

Application | Decoration construction, upholstery, industry instruments | |||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | |||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316 | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <253 | <253 | <200 | <200 | ||

Pictures of Stainless angle steel; high quality angle steel

- Q: Can steel angles be used for reinforcing steel structures?

- Steel angles are capable of reinforcing steel structures. Their versatility and widespread use in construction projects stem from their strength and durability. Steel angles serve as reinforcements to fortify and provide additional support to steel structures including beams, columns, and trusses. To enhance the overall structural integrity of steel structures, steel angles are often used in conjunction with other reinforcing materials such as steel bars or mesh. The angle shape of steel angles facilitates easy welding or bolting, making them a popular choice for reinforcing steel structures. Moreover, steel angles are available in various sizes and thicknesses, offering flexibility in design and application. All in all, steel angles prove to be an effective and commonly employed option for reinforcing steel structures.

- Q: How are steel angles used in structural framing?

- Steel angles are commonly used in structural framing as they provide stability and support. They are often used to reinforce corners and joints, adding strength to the overall structure. Steel angles are also used as braces and supports in various construction projects, helping to distribute weight and prevent sagging or collapsing.

- Q: Can steel angles be used in residential construction?

- Indeed, residential construction can make use of steel angles. These versatile structural elements find widespread application in various construction projects, including residential buildings. They are commonly employed for framing, reinforcing, and providing structural support in walls, roofs, and floors. In residential construction, steel angles are favored due to their notable strength, durability, and capacity to withstand heavy loads. Their ease of installation, whether by welding, bolting, or screwing, renders them suitable for a wide array of construction endeavors. Furthermore, the corrosion resistance of steel angles can be enhanced through galvanization or coating, assuring their longevity. In essence, steel angles present a dependable and cost-effective option for residential construction.

- Q: What is the difference between the main keel and the angle steel and the channel steel?

- Light steel keel is made of high-quality continuous hot-dip galvanized sheet and used as raw material and rolled by cold bending technology. It is used for decorative design of non load bearing wall and building roof with plasterboard, decorative gypsum board and other lightweight board. The utility model is suitable for the decoration of the roof of various buildings, the internal and external wall of the building and the basic material of the trellis suspended ceiling. According to the use of ceiling keel and partition keel, in accordance with the form of section V, C, T, L keel. Ceiling keel is divided into: the main keel and vice keel. The main keel is the weight of the weight of the suspended ceiling.

- Q: Can steel angles be used for support structures in stadiums or arenas?

- Yes, steel angles can be used for support structures in stadiums or arenas. Steel angles are commonly used in construction and engineering projects due to their strength, durability, and versatility. They are often utilized in structural applications where load-bearing support is required, making them suitable for supporting the weight of stadium or arena structures. Steel angles can be used as beams, columns, or trusses to provide the necessary support and stability for large structures. Their ability to withstand heavy loads and resist bending or warping makes them a popular choice for constructing stadium roofs, grandstands, and other support systems. Additionally, steel angles can be easily fabricated and customized to meet specific design requirements, allowing for efficient and cost-effective construction of stadium and arena support structures.

- Q: Galvanized steel angles under what conditions?

- Galvanized angle itself coated zinc and iron rust, common need to be coated with a layer of anti rust paint in the construction process, so the galvanized angle in the construction without paint. Suitable for field and outdoor support and Engineering

- Q: Can steel angles be used in mezzanine construction?

- Yes, steel angles can be used in mezzanine construction. Steel angles are often used as structural supports in mezzanine construction due to their strength and versatility. They can be used to create the framework and provide stability for mezzanine floors, making them a popular choice in this type of construction.

- Q: What is the lifespan of steel angles?

- The durability and longevity of steel angles can be influenced by several factors, including the quality of the steel, the environmental conditions in which they are used, and the level of maintenance they receive. It is widely recognized that steel angles are highly durable and long-lasting, which is why they are commonly chosen for construction and structural purposes. When high-quality steel angles are manufactured and maintained properly, they can endure for several decades or even longer. However, their lifespan can be significantly reduced by factors such as exposure to harsh weather, corrosive environments, and neglectful maintenance. To ensure the maximum lifespan of steel angles, it is crucial to select the appropriate steel grade for the specific application, carry out proper installation, and regularly inspect and maintain them. This may involve actions such as periodically applying paint or protective coatings to prevent corrosion, conducting routine inspections to detect any signs of wear or damage, and promptly addressing any issues that arise. In conclusion, the lifespan of steel angles can vary, but with adequate care and maintenance, they can last for many years, providing strength and stability to a wide range of structures and applications.

- Q: Can steel angles be used for support structures in sports arenas or stadiums?

- Yes, steel angles can be used for support structures in sports arenas or stadiums. Steel angles are commonly used in construction due to their strength, durability, and versatility. They are particularly suitable for support structures as they can withstand heavy loads and provide stability. In sports arenas or stadiums, steel angles can be used for various purposes such as supporting the roof, creating seating platforms, constructing staircases, and forming the framework for walls and partitions. The flexibility of steel angles allows architects and engineers to design custom support structures that meet the specific requirements of each sports arena or stadium. Furthermore, steel angles can be easily fabricated and joined, making them ideal for the construction of complex support systems. Their ability to resist bending, twisting, and compression ensures the overall stability and safety of the structure. Moreover, steel is a sustainable material that is 100% recyclable. This makes it an environmentally friendly choice for sports arenas or stadiums. By using steel angles for support structures, the construction industry can contribute to reducing carbon emissions and promoting a more sustainable future. Overall, steel angles are a reliable and efficient choice for support structures in sports arenas or stadiums. Their strength, durability, versatility, and sustainability make them an excellent option for ensuring the safety and stability of these large-scale structures.

- Q: Can steel angles be used as structural supports?

- Indeed, structural supports can be provided by steel angles. Construction and engineering projects frequently employ steel angles due to their remarkable strength and stability. Their distinctive L-shape design renders them perfectly suited for lending support and ensuring structural integrity to various structures. Buildings, bridges, and other infrastructure projects often incorporate steel angles as beams, braces, or supports. These angles are capable of bearing heavy loads and resisting bending and compression forces, thereby establishing themselves as a dependable choice for structural support. Moreover, the ease of fabrication and installation associated with steel angles renders them a cost-effective solution for construction purposes.

Send your message to us

Stainless angle steel; high quality angle steel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords