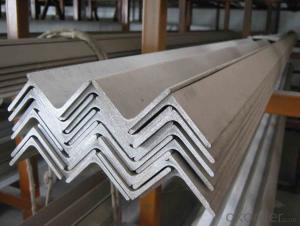

Angle Steel ASTM A36 or GB Q235 Q345B or Equivalent for ALL SIZES

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel angles be customized or fabricated to specific requirements?

- Yes, steel angles can be customized or fabricated to specific requirements.

- Q: Can steel angles be used in sign support structures?

- Yes, steel angles can be used in sign support structures. Steel angles are commonly used in construction as they provide excellent strength and structural support. They can be easily welded or bolted together to form sturdy sign support structures that can withstand various weather conditions and loads.

- Q: Bearing capacity of angle steel and channel steel

- Channel steel is a strip of steel with a cross section. Section steel with groove shape.Channel steel is a kind of carbon structural steel used for construction and machinery. It is a complex section steel. Its cross section has a groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing, etc.. In use, it requires better welding, riveting performance and comprehensive mechanical properties. The raw material steel billet for channel steel is carbon or low alloy steel billets with a carbon content of not more than 0.25%. The finished channel steel is delivered by hot forming, normalizing or hot rolling. The specifications are expressed in millimeters of height (H) * leg width (b) * waist thickness (d), such as 100*48*5.3, which means waist height is 100 mm, leg width is 48 mm, waist thickness is 5.3 mm channel, or 10# channel steel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25#a, 25#b, 25#c and so on.Channel steel is divided into ordinary channel steel and light channel steel. Standard Specification for hot-rolled plain channel steel is 5-40#. Specifications for hot rolled flexible channel steel supplied by supply and demand agreement are 6.5-30#. Channel steel is mainly used for building structures, vehicle manufacturing, other industrial structures and fixed plates, cabinets, etc., and channel steel is often used in conjunction with i-beam.

- Q: Can steel angles be used for fencing or gating?

- Certainly, fencing or gating can indeed utilize steel angles. Steel angles are incredibly versatile and frequently employed in various construction endeavors, such as fencing and gating. They possess the essential attributes of strength, durability, and stability that are imperative for these particular applications. The assembly of a robust framework for fencing panels or gates can be effortlessly achieved by welding or bolting steel angles together. Moreover, these angles can be galvanized or coated to augment their resistance against corrosion, rendering them highly suitable for outdoor utilization. All in all, steel angles present a dependable and economically viable resolution for fencing and gating projects.

- Q: Can steel angles be used in lighting or electrical fixtures?

- Lighting or electrical fixtures can utilize steel angles. These angles are highly adaptable and can be easily shaped and sized to suit various needs. In lighting fixtures, steel angles serve as secure brackets or supports for the lighting components. Their presence offers stability and strength to the fixture, ensuring it can endure the weight of the lighting elements. Similarly, in electrical fixtures, steel angles function as frames or mounting brackets for electrical components like switches, outlets, or junction boxes. The toughness and load-bearing capacity of steel angles make them an excellent option for these purposes, as they can handle the weight and stress associated with lighting or electrical fixtures. Furthermore, steel angles can be effortlessly painted or coated to match the aesthetic requirements of the fixture. Therefore, they are a versatile and pragmatic choice for lighting or electrical applications.

- Q: What are the common applications of steel angles in architecture?

- Steel angles are widely used in architecture for various applications due to their versatility and strength. Some common applications of steel angles in architecture include: 1. Structural support: Steel angles are often used as structural support elements in building construction. They can be welded or bolted together to form a sturdy framework that provides strength and stability to the structure. 2. Framing: Steel angles are commonly used in framing applications such as door and window frames, as well as in the construction of roof trusses. They provide rigidity and support to the overall structure, ensuring that it remains stable and durable. 3. Reinforcement: Steel angles are often used to reinforce concrete structures. They can be embedded into concrete walls, columns, and beams to enhance their load-bearing capacity and resistance to deformation. 4. Staircases and handrails: Steel angles are frequently used in the construction of staircases and handrails. They provide a strong and durable framework that ensures the safety and stability of these architectural elements. 5. Architectural detailing: Steel angles are also utilized for architectural detailing purposes. They can be used to create decorative elements such as cornices, brackets, and ornamental features that add aesthetic appeal to the building. 6. Industrial applications: Steel angles find application in industrial settings, such as factories and warehouses, where they are used to create sturdy platforms, mezzanines, and equipment supports. Overall, steel angles are a versatile and reliable material that offers numerous benefits for architectural applications. Their strength, durability, and flexibility make them an ideal choice for a wide range of architectural structures and features.

- Q: Can steel angles be used for shelving?

- Yes, steel angles can be used for shelving. Steel angles are commonly used in shelving systems due to their durability and strength. They provide sturdy support for shelves and can withstand heavy loads. Additionally, steel angles are versatile and can be easily customized to fit different shelving configurations. They are often used in industrial settings, warehouses, garages, and even in residential applications where a strong and reliable shelving solution is desired.

- Q: What are the different types of steel angle profiles?

- There exists a variety of steel angle profiles, each possessing distinct characteristics and uses. Here are some of the most prevalent types: 1. Equal angle: Designed with sides of equal length, this steel angle is predominantly employed for structural purposes, such as providing support for beams or framing. It ensures equal strength and stability in both directions, making it a popular choice in the construction and manufacturing sectors. 2. Unequal angle: This particular steel angle, as suggested by its name, features sides of unequal length. It finds common application in scenarios where enhanced strength is required in one direction, like supporting shelves or bracing components. Unequal angle profiles are also utilized in the construction of bridges and buildings. 3. L-shaped angle: This steel angle possesses one longer side, forming an L shape. It is commonly utilized as a support or bracket in various industries, including furniture manufacturing, automotive production, and construction. 4. Slotted angle: Slotted angle profiles are characterized by holes or slots along the angle's length, facilitating effortless attachment and adjustment of components. They are frequently employed in shelving units, workbenches, and storage systems, offering flexibility and versatility in design. 5. Stainless steel angle: Manufactured from corrosion-resistant steel, stainless steel angles are ideal for environments with moisture and harsh chemicals. They are commonly used in the food processing, pharmaceutical, and chemical industries. 6. Galvanized angle: Galvanized steel angles are coated with a protective layer of zinc, which prevents corrosion and rusting. They are extensively utilized in outdoor applications, such as fencing, signposts, and support structures, where exposure to weather elements is a concern. These are merely a few examples of the various steel angle profiles available, each offering specific advantages and applications based on project requirements.

- Q: How do you prevent steel angles from vibrating?

- There are several ways to prevent steel angles from vibrating: 1. Damping materials: Applying damping materials such as rubber pads, neoprene, or foam between the steel angles and the structure they are attached to can help absorb and dissipate vibrations. 2. Structural modifications: Reinforcing the steel angles by adding additional supports or bracing can help reduce vibrations. By increasing the stiffness and rigidity of the structure, the tendency for vibrations to occur can be minimized. 3. Mass modification: Adding additional mass to the steel angles can help stabilize them and reduce vibrations. This can be achieved by attaching weight plates or heavier components to the angles. 4. Tensioning: Applying tension to the steel angles can help reduce vibrations by increasing their natural frequency and stiffness. This can be done by tightening bolts or using tensioning devices. 5. Vibration isolation: Using vibration isolation techniques, such as mounting the steel angles on rubber isolators or spring mounts, can help isolate them from the surrounding structure and minimize vibration transmission. 6. Resonance avoidance: Identifying and avoiding the natural frequencies of the steel angles is crucial in preventing vibrations. By analyzing the structural dynamics and adjusting the design or operational conditions, resonance can be avoided, reducing the chances of vibrations. 7. Regular maintenance: Regularly inspecting and maintaining the steel angles can help identify any issues or potential sources of vibrations. This includes checking for loose connections, corrosion, or any signs of wear and tear that could contribute to vibration problems. It is important to note that the specific method(s) chosen to prevent steel angles from vibrating will depend on various factors, including the application, structural design, and environmental conditions. Consulting with a structural engineer or vibration specialist is recommended to ensure the most effective and appropriate solution is implemented.

- Q: What are the common methods of joining or connecting steel angles together?

- Common methods of joining or connecting steel angles together include welding, bolting, and using angle brackets or cleats.

Send your message to us

Angle Steel ASTM A36 or GB Q235 Q345B or Equivalent for ALL SIZES

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords