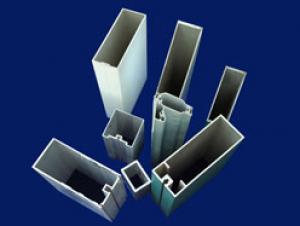

Aluminum Construction Profiles - Aluminum Frame Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium profile

1) Alloy: AA6061, AA6063

2) Temper: T5, T6

3) Series of surface treament:

1. Mill Finished

2. Anodizing: Silver, champagne, light bronze, dark bronze, black, light titanium, dark titanium.

3. Electrophoretic Coating: Silver, champagne, bronze, black, light bronze, dark bronze.

4. Electrostatic Color Powder Coating: Normal color, special color.

5. Fluorocarbon Powder Spraying: Normal color, special color.

6. Wood Grain Coating: Import paper, domestic paper.

- Q: What are the different surface treatments for aluminum profiles?

- Aluminum profiles can be treated with various surface treatments, each offering its own advantages and characteristics. Anodizing is a popular method that involves forming a protective oxide layer on the aluminum surface. This enhances the corrosion resistance and allows for the aluminum to be dyed in different colors, creating a sleek and modern finish. Another commonly used technique is powder coating, where a dry powder paint is applied and cured under heat to create a durable coating. This provides excellent resistance to scratching, chipping, and fading, making it perfect for applications that require long-lasting and vibrant finishes. Painting is a versatile option that allows for a wide variety of color choices and finishes. Aluminum profiles can be painted using different methods, such as spray painting or electrostatic coating. This creates a smooth and attractive appearance suitable for both indoor and outdoor use. For a distinctive and decorative look, brushing is a technique that involves brushing the aluminum surface with a wire brush or abrasive material. This creates a textured finish, often chosen for architectural and design applications that require a unique and stylish appearance. Ultimately, the choice of surface treatment for aluminum profiles depends on the specific requirements of the application. Factors such as corrosion resistance, durability, aesthetic appeal, and functionality all play a vital role in determining the most suitable surface treatment method.

- Q: What are the different bending radius options for aluminum profiles?

- The bending radius options for aluminum profiles vary depending on the specific profile design, thickness, alloy, and temper. Generally, aluminum profiles can be bent to a radius of 1.5 to 2 times the profile's thickness. However, this can be influenced by factors such as the alloy's strength, the profile's cross-sectional shape, and whether it has internal or external radii. For thicker profiles, the minimum bending radius tends to be larger, while thinner profiles can achieve smaller bending radii. It is important to note that attempting to bend a profile below its recommended minimum bending radius can lead to deformation, cracking, or even failure. In some cases, aluminum profiles can undergo cold bending, where they are bent without the need for heating. Cold bending allows for tighter radii and can be achieved through specialized bending equipment or processes. However, it is essential to consult the manufacturer's specifications or seek professional advice to determine the appropriate bending radius options for specific aluminum profiles.

- Q: What are the dimensions and sizes of aluminum profiles?

- The dimensions and sizes of aluminum profiles can vary greatly depending on their intended use and design. They can range from small and narrow profiles, such as 10mm x 10mm square tubes, to larger and wider profiles, such as 100mm x 100mm square tubes. Additionally, aluminum profiles can come in various shapes, including square, rectangular, round, and custom shapes, to accommodate different applications and structural requirements. It is important to consult specific product catalogs or manufacturers for precise dimensions and sizes of aluminum profiles.

- Q: What are the methods to prevent water infiltration in the gaps between aluminum profiles during the installation process?

- <p>To prevent water from getting into gaps between aluminum profiles during installation, use high-quality sealants and gaskets. Ensure proper alignment and fit of the profiles to minimize gaps. Install weep holes to allow water to drain out. Apply a water-resistant membrane or flashing behind the profiles. Regularly inspect and maintain the installation to identify and fix any issues promptly. Proper installation techniques and materials selection are crucial to prevent water infiltration.</p>

- Q: This question asks for a list of various fastening methods used to connect aluminum profiles to the structural frames of buildings.

- <p>There are several types of fasteners used to attach aluminum profiles to building frames, including: 1) Bolts and Nuts: Commonly used for strong, secure connections. 2) Rivets: Provide a permanent connection that is resistant to vibration. 3) Self-Tapping Screws: Can be used in materials without pre-drilling. 4) Structural Glue: Offers a strong bond and is often used in combination with mechanical fasteners. 5) Welding: Used for permanent, load-bearing connections, though not common for aluminum due to the risk of thermal distortion. 6) Clamps and Brackets: Used for temporary or adjustable connections. 7) Adhesive Tapes: Provide a quick and easy method of attachment, though not as strong as other methods. Each type of fastener has its own advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: What are the different surface sandblasting options for aluminum profiles?

- There are several surface sandblasting options for aluminum profiles, including: 1. Aluminum oxide blasting: This involves using aluminum oxide particles to remove surface impurities and create a smooth finish on the aluminum profiles. It is commonly used for cleaning and preparing the surface before further treatments or coatings. 2. Glass bead blasting: Glass beads are used to blast the aluminum surface, which helps to remove oxidation and provide a satin-like finish. This method is often employed for decorative applications or to achieve a specific aesthetic look. 3. Walnut shell blasting: Crushed walnut shells are used as the blasting media to gently remove contaminants and provide a smooth, matte finish on aluminum profiles. It is a non-aggressive option that is suitable for delicate or sensitive surfaces. 4. Steel shot blasting: Steel shot particles are propelled onto the aluminum surface to remove scale, rust, and other imperfections. This method is ideal for heavy-duty cleaning and surface preparation, especially for profiles that will undergo subsequent coatings or treatments. Overall, the choice of sandblasting option for aluminum profiles depends on the desired outcome, surface condition, and the specific requirements of the application.

- Q: Is it possible to recycle aluminum profiles and incorporate them into new construction projects?

- <p>Yes, aluminum profiles can be recycled and reused in new building projects. Aluminum is highly recyclable, and the recycling process is energy-efficient, requiring only 5% of the energy needed to produce new aluminum. Recycled aluminum maintains its properties, making it suitable for various applications in construction. This practice not only conserves resources but also reduces waste and environmental impact.</p>

- Q: Are aluminum profiles resistant to chemicals and acids?

- Generally, aluminum profiles exhibit resistance to chemicals and acids due to their natural oxide layer, making them appropriate for diverse industrial uses. Nevertheless, the level of resistance may differ depending on the exact type of chemical or acid employed, as certain aggressive substances can still corrode aluminum. In these instances, one can enhance the resistance by applying supplementary protective coatings or surface treatments. To guarantee the utmost performance and durability, it is recommended to consult experts or manufacturers to ascertain the compatibility of aluminum profiles with specific chemicals or acids.

- Q: Is it possible to incorporate recycled aluminum extrusions into a construction project?

- <p>Yes, you can use recycled aluminum extrusions in your building project. Recycled aluminum is not only environmentally friendly but also offers the same strength and durability as new aluminum. It is commonly used in construction for framing, window and door profiles, and structural components. Ensure that the recycled aluminum meets the required industry standards for your project to guarantee quality and performance.</p>

- Q: What are the advantages of using aluminum profiles in the automotive aftermarket?

- There are several advantages of using aluminum profiles in the automotive aftermarket. Firstly, aluminum profiles are lightweight, which helps in reducing the overall weight of the vehicle. This, in turn, improves fuel efficiency and performance. Secondly, aluminum profiles offer high strength-to-weight ratio, making them durable and capable of withstanding heavy loads and impacts. Additionally, aluminum is corrosion resistant, which ensures long-lasting performance and reduces maintenance costs. Lastly, aluminum profiles can be easily customized and fabricated, offering flexibility in design and allowing for easy installation in various automotive applications.

Send your message to us

Aluminum Construction Profiles - Aluminum Frame Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords