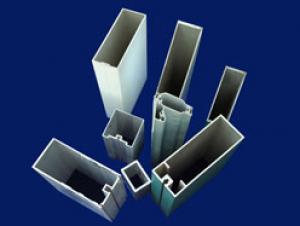

Aluminum Profiles for Glass - Industrial Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: Is it possible to utilize aluminum profiles in the construction or structure of commercial buildings and factories?

- <p>Yes, aluminum profiles are commonly used in commercial buildings and factories due to their strength, durability, and lightweight properties. They are ideal for constructing frameworks, window and door frames, and support structures. The corrosion resistance of aluminum also makes it suitable for industrial environments where exposure to harsh chemicals or weather conditions is a concern. Additionally, aluminum profiles are easy to maintain and can be recycled, contributing to the sustainability of construction projects.</p>

- Q: Are aluminum profiles recyclable and can they be used again in flooring applications?

- <p>Yes, aluminum profiles can be recycled and reused in flooring applications. Aluminum is a highly recyclable material, with recycling processes that retain its properties without loss in quality. This makes it an environmentally friendly choice for flooring as it reduces waste and conserves resources. Recycled aluminum can be used to create new profiles for flooring systems, maintaining strength and durability while offering a sustainable solution.</p>

- Q: What are the advantages of utilizing aluminum profiles in construction projects in terms of environmental impact?

- <p>Aluminum profiles in construction offer several environmental benefits. They are highly recyclable, which reduces waste and conserves natural resources. Aluminum is lightweight, reducing transportation emissions. It also has a high strength-to-weight ratio, allowing for more efficient use of materials. Additionally, aluminum has excellent thermal conductivity, which can contribute to energy efficiency in buildings. Furthermore, aluminum production technology has advanced to reduce energy consumption and emissions during the manufacturing process. Overall, the use of aluminum profiles can lead to more sustainable and environmentally friendly construction practices.</p>

- Q: Can aluminum profiles be used in automotive applications?

- Yes, aluminum profiles can be used in automotive applications. Aluminum profiles are lightweight, strong, and corrosion-resistant, making them suitable for various automotive components such as body panels, chassis parts, and engine components. Their use helps reduce the overall weight of the vehicle, improving fuel efficiency and performance.

- Q: Can aluminum profiles be used in interior design applications?

- Yes, aluminum profiles can be used in interior design applications. They are versatile, lightweight, durable, and available in various finishes and designs. Aluminum profiles can be used for creating furniture, partitions, shelving, lighting fixtures, decorative elements, and more, adding a modern and sleek aesthetic to interior spaces.

- Q: What are the different surface texturing options for aluminum profiles?

- Some of the different surface texturing options for aluminum profiles include anodizing, powder coating, brushing, polishing, and sandblasting. These techniques can be used to create different textures and finishes on the surface of the aluminum profiles, enhancing their appearance and providing additional protection against corrosion and wear.

- Q: Can aluminum profiles be used in lighting fixture manufacturing?

- Aluminum profiles are indeed suitable for the manufacturing of lighting fixtures. In the lighting industry, aluminum is widely employed because of its many advantageous qualities. It possesses light weight, durability, and corrosion resistance, which make it perfect for both indoor and outdoor lighting fixtures. By easily molding and manipulating aluminum profiles, one can create diverse designs and forms, thereby enabling innovative and imaginative lighting solutions. Moreover, these profiles can be coated or anodized, thereby enhancing their visual appeal and providing extra protection against damage. All in all, due to their versatility, functionality, and aesthetic appeal, aluminum profiles are highly favored in the manufacturing of lighting fixtures.

- Q: What are the various energy-saving characteristics that can be incorporated into aluminum profiles?

- <p>Aluminum profiles can incorporate several energy-saving features to enhance thermal insulation and reduce energy consumption. These include: 1. Thermal breaks: Inserts that reduce heat transfer between the interior and exterior of a profile. 2. Multi-chamber designs: Multiple air chambers within the profile that act as insulators. 3. Low-E coatings: Reflective coatings that reduce heat transfer. 4. Insulating glass units: Double or triple glazed units with gas fills that provide superior insulation. 5. Passive solar design: Profiles designed to maximize heat gain in winter and minimize it in summer. 6. High-performance seals: Gaskets and seals that minimize air infiltration. 7. Aerodynamic shapes: Profiles that reduce air resistance and heat loss. These features can significantly contribute to energy efficiency in buildings.</p>

- Q: What are the different sizes and dimensions of aluminum profiles?

- The different sizes and dimensions of aluminum profiles can vary greatly depending on the specific application and manufacturer. They can range from small, narrow profiles with dimensions of a few millimeters to larger, wider profiles with dimensions of several inches or more. The length of the profiles can also vary, typically ranging from a few feet to several meters.

- Q: What are the advantages of using aluminum profiles in the automotive aftermarket?

- There are several advantages of using aluminum profiles in the automotive aftermarket. Firstly, aluminum profiles are lightweight yet strong, making them ideal for automotive applications. By using aluminum profiles instead of traditional steel or other heavy materials, vehicles can be made lighter, resulting in improved fuel efficiency and reduced emissions. This is especially important in today's world where environmental concerns are at the forefront. Secondly, aluminum profiles offer excellent corrosion resistance. This is crucial for automotive parts that are exposed to various weather conditions and road salt. Unlike steel, aluminum does not rust, making it a durable and long-lasting choice for aftermarket automotive components. Additionally, aluminum profiles can be easily customized and shaped to fit specific design requirements. This flexibility allows for the creation of complex and intricate designs that can enhance the aesthetics and functionality of aftermarket automotive parts. Whether it is for body panels, interior trim, or structural components, aluminum profiles can be easily tailored to meet the unique needs of each vehicle. Furthermore, aluminum profiles have excellent thermal conductivity. This means that they can efficiently dissipate heat, making them suitable for applications such as heat exchangers or cooling systems in the automotive aftermarket. This property helps to prevent overheating and ensures optimal performance of the vehicle. Lastly, aluminum is a highly recyclable material. This makes it a sustainable choice for the automotive aftermarket, as it can contribute to reducing waste and minimizing the environmental impact. By using aluminum profiles, manufacturers and consumers can participate in the circular economy by recycling and reusing the material, thereby reducing the overall carbon footprint. In conclusion, the advantages of using aluminum profiles in the automotive aftermarket are clear. From weight reduction and improved fuel efficiency to corrosion resistance, customizability, thermal conductivity, and sustainability, aluminum profiles offer numerous benefits that make them an excellent choice for aftermarket automotive components.

Send your message to us

Aluminum Profiles for Glass - Industrial Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords